Build smokehouse yourself - construction manual for the walls

- functionality

- Build smoking oven - construction manual

- EXTRA - build wooden chamber

They love to grill and smoke and are an absolute DIY fan ">

The smokehouse is considered a precursor to the refrigerator. Before the food could be preserved by cold or vacuum packaging, only the smoking or salting remained. A different way to keep germs and fungi away was just a few decades ago just not yet. These preservation methods were not only quite effective - especially the smoking produced a very special, distinctive taste. The smoking of meat and fish was therefore not abandoned even after the advent of refrigerators, but retain as an extension of the culinary spectrum. But anyone can buy a finished ham or smoked salmon - the self-smoking is becoming more of a hobby for many. Read in this article how you can enjoy homemade smoked delicacies.

Simple and inexpensive - the smokehouse

In a smokehouse are lower temperatures than in a smoker. That makes his construction easier. The cooking takes in the smokehouse but also much longer. Also in terms of taste are significant differences between the quick preparation in the smoker and the time-consuming smoking: The grilled food from the smoker should be consumed immediately after heating. When the meat gets cold from the smoker, it becomes very dry, tough and barely edible. On the other hand, meat and fish from the smokehouse can be kept for weeks.

functionality

A smokehouse consists of a tall, slim, cylindrical room with two chambers. Both chambers have their own doors. The lower chamber is for lighting the smoke fire. There, the suitable for smoking fuel, such as beech wood, inserted. In the large chamber above, the smoking material is hung up. Many hobby smokers use their smokers for trout, salmon or eels. So you can make yourself in a few hours already very delicious delicacies yourself. To smoke a ham takes much longer. But once you really get the taste of the smoked dishes, you will get the trick out of the pig.

Build smoking oven - construction manual

A masonry smoker in the garden is the highlight of every barbecue party. Here a connoisseur and experts can show what is in it. Especially if the stove fits visually to the facade of the house, you have here with a few simple steps a real eye candy, which can make the neighbors jealous. Fortunately, this is the easy part, especially if you have a verklinkerte facade: The clinker bricks are ideal for building a smokehouse. Of course, you can also with three to four hollow blocks, as used in horticulture, build an incense tower. But that looks very tinkered and does not live up to the claim of a truly self-built oven. In addition, this solution is limited to the cross section of the hollow chamber block. A neat, brick smoker made of clinker bricks can be designed freely in its size.

The construction manual provides:

- flat shovel

- 4 boards with a width of about 20 cm

- 2-3 sacks of ready-mixed concrete

- 3-4 sacks of ready to use mortar (50 kg)

- a bag of gravel

- large bath for mixing concrete and mortar

- 1 square meter of structural steel mat

- Approx. 200 clinker bricks in normal format

- 10 x galvanized threaded rods (diameter 1 - 2 cm)

- hacksaw

- steel strips

- 2 square meters of stainless steel sheet for doors

- spirit level

- ruler

- trowel

- Quast

- Angle grinder with cutting disc for stainless steel

- exhaust pipe

IMPORTANT: Before you buy the hardware store empty, you should calculate exactly how many stones and how many meters of threaded rod you need for the suspension and the bracing of the false ceiling. Be sure to read the complete instructions in front of the walls to understand the principle. You do not necessarily have to use the number of rows and the size of the smoker as described in this manual. If you have internalized the principle, you can also design your own smokehouse according to your ideas.

1st foundation

Like any decent masonry building, the earthen smokehouse begins with a neat foundation. For this purpose, about 1 square meter is staked straight and excavated to a depth of about 15 cm.

The soil is laid out with gravel and pulled smooth. With the four boards, the foundation is turned on. It is sufficient a bottom plate of about 1 m² and 15 cm thickness. Of course, a steel mesh mat can not be missing. The high pressure load of the masonry would otherwise break the plate quickly. After the concrete has been mixed and poured, it will be left to rest for two days. Then it can be switched off and the walls can begin.

2. walls

A practical basic form is already achieved with 4 stone widths and 3 stone depths. First build an "outer circle" and then a staggered "inner circle" - this is the first row of stones.

When walling always pay attention to a 50% overlap. This creates the most beautiful joint and the highest stability. To the edge of the foundation should be left about 1 stone width distance. If you want to build a larger stove, you have to lay out the foundation accordingly wide. When walling always on straight growth, exact alignments, constant distances between the stones (about 1 cm) and vollfugiges placing the stones pay attention.

In the next row you leave 2 stone widths free for the combustion chamber. The combustion chamber is bricked approx. 50 cm high.

3. Move false ceilings

Now wall the next row so that the stones close the combustion chamber again. For this purpose, a simple support structure made of wood in the desired height is installed: A suitably cut board that is supported with a few wooden feet, is already sufficient.

In order for the stones to sit stably in the fall, they can additionally be fixed to each other with steel straps.

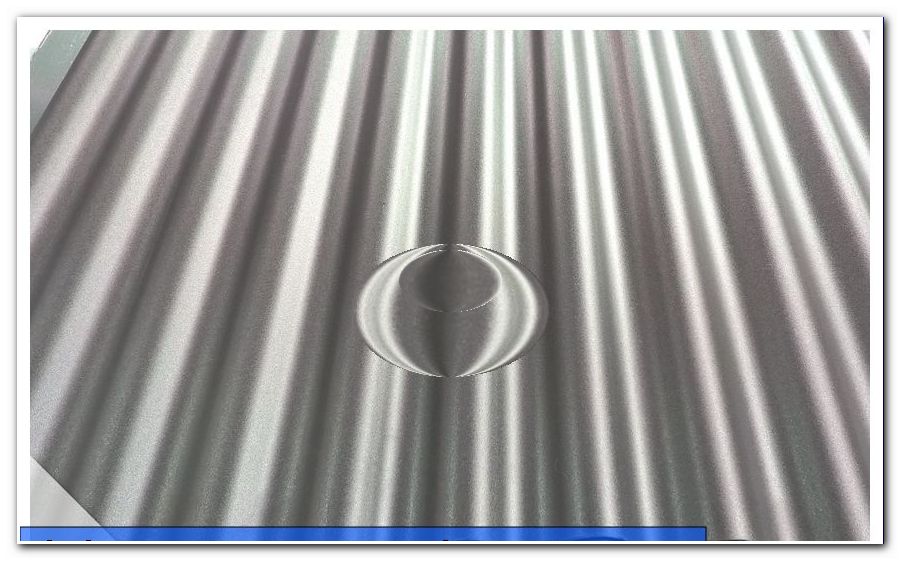

Then the smokehouse needs a false ceiling with a 10 cm x 10 cm hole in the middle - this separates the combustion chamber and smokehouse from each other.

The false ceiling ensures that the smoking material only gets smoke but no open flame. The masonry false ceiling must be walled up conscientiously Vollfugig. Otherwise you have no stability and the ceiling collapses quickly.

On the newly bricked row now cross bars are incorporated. These can be simple threaded rods - cut the rods to the desired length with the metal saw. Then save the space for the crossbars in the brick - by picking out the stone and sinking the crossbars - four for each direction. The cross bars must just complete with the row. Then the crossbars are covered with bricks as in the picture. The stones of the middle "circle" are arranged so that the hole in the middle remains.

Thereafter, the outer circle is bricked in the offset as usual.

4. Finish masonry

Now a tower of about 2 meters height is being built. The cleaner the masonry, the more impressive the result will be. Again, in this construction manual, the two-chamber principle is used: The lower, smaller chamber for the fuel and the larger chamber for the smoker. The crossbars for hanging fish and meat are simply inserted into the storage joint or sunk back into the stone - in the row, in which they are of course to hang later. You have to think about this well and calculate where it should be later. The crossbars are then walled solid. This saves you the need to drill afterwards. The brick oven is left for two days.

5. Doors

Then it is equipped with doors made of sheet steel. These are cut to fit with the angle grinder and provided with hinges. The hinges screw the door to the masonry. The edges of the sheets are ground round so nobody can hurt themselves. The handle of the doors should, however, be made of wood, otherwise you burn your fingers when opening.

6. Build the roof

As a roof, the simplest solution is again a masonry or concrete false ceiling. They work just like the false ceiling between the burning and smokehouse. In this is then installed from the top of a small piece of pipe as a trigger - finished is the masonry smokehouse.

The fresh masonry is carefully turned away with the tassel. So you get a more beautiful joint.

The advantage of a brick smoking oven is also that it can not burn down. In order to burn it dry, so unrestrained fire can be kindled in it. When he stops steaming, he is ready for the first load of incense.

A construction manual for everyone

Because internet is full of designs and ways to build your own smoker. The simple design of this very special preparation cabinet makes it possible that everyone can find the appropriate building instructions for themselves. We recommend that you start with a simple smoker first and then gain your own experience. Who has come to the taste, can gradually work up to the nobler variant. After all, no one is helped with a chic, brick-built smoker, when the good piece is then left unused in the garden.

EXTRA - build wooden chamber

A wood smokehouse is not only an ecological and visually appealing alternative to the drum oven. The natural material wood is also a flavor enhancement for the smoking product. However, only untreated wood comes into question for this construction manual! Lacquered wood, chipboard or veneer are not suitable for the au of a smokehouse made of wood! That's why the ideal material for the shuttering is tongue and groove boards made of solid wood. Simple, untreated ceiling panels are ideal.

You need:

- 5 10 × 10 bars of about 2 meters in length

- 2 packages ceiling panels

- Insulating material (rock wool, no Styrofoam)

- aluminum foil

The wood stove is built according to the proven two-chamber principle. Both chambers get an inside and an outside formwork. In between comes the insulation material. So no heat is lost and the stove does not get too hot from the outside. There are no limits to creativity for the user here. The combustion chamber should be lined with several layers of aluminum foil so that it does not accidentally set the whole stove on fire. Also, the wooden smoke box should first be smoked dry before the first meat is hung. For wood smoke ovens, of course, you have to pay special attention to the temperature. To be on the safe side, an electric heating element should be used with this type of stove. This avoids the danger of burning off the oven.