Lay cork floor yourself - instructions and costs for the professional

- Facts - cork floor

- surface

- manufacturing

- selection

- Instructions: Lay cork flooring floating

- 1. Lay down the impact sound

- 2. Lay cork panels

- 3rd click function

- 4. Theses

- Glue and seal cork parquet

- 1. Balance ground

- 2. Glue cork boards together

- 3. Seal

- Costs: Lay cork floor

- Cost overview

- Tips for quick readers

Cork has numerous advantages, so it is not surprising if it is increasingly selected as flooring in the living spaces again. Especially for the bedrooms and children's rooms offers a cork floor improved noise insulation and remains flexible and elastic. There are different types of cork floors. Here are the instructions for the different types of installation and what costs this raises a professional.

Despite the elastic and insulating effect, a cork flooring is not quite as robust as many other floors. Therefore, the cork floor is also more suitable for living spaces. There are considerable differences in cork flooring, also in terms of the way it is laid. Here we show you the instructions for laying floating cork flooring and a working instruction for a fully glued floor of cork tiles. If you would rather have a professional do the work, then below you will find an overview of the costs that you have to expect. The prices of the craftsmen but are regionally different.

You need this:

- jigsaw

- table saw

- Japan saw fine

- rubber hammer

- bat

- crowbar

- fitting wedges

- ruler

- pencil

- Carpet Knife / Cutter

velor role - notched trowel

- roller

- Leveling compound

- Tiefengrund

- Korkkleber

- Cork tiles

- Sealing for cork

- Korkpaneele

- sound insulation

Advantageous natural flooring

There are many reasons for a floor covering with cork. Cork simply provides a warmer and softer foot feel. So in cottages and especially in the nursery a cork flooring is the best choice. The pleasantly warm surface invites children to play for hours directly on the floor. No mother has to be afraid, the children could be cold. Even if the little ones are jibbing and falling, the consequences are much lower than on a stone or wooden floor. The cleaning is very easy despite the warm surface. Here's how it's done: Clean the cork floor

Facts - cork floor

surface

However, the exact nature of the surface depends on the type of cork floor. The most popular type of cork flooring is very similar to the laminate. The surface is similarly sealed and sometimes even has a wood decor. So the floor does not look like a laminate floor after installation. But the inner life consists of the warm flexible cork. As a result, a footfall sound insulation is supported very effectively, because this floor is laid floating. How to lay the floor yourself, we show in the first manual.

Cork tiles, on the other hand, usually have a natural cork appearance, which is sealed with certain substances. These often square panels are glued to the floor over the entire surface and must then be sealed again depending on the material. This flooring is particularly suitable for laying on a floor heating.

manufacturing

Cork is obtained from certain oak trees called cork oaks. This tree has a particularly thick bark that is peeled off every nine years. For the production of both types of cork floors mentioned above, the bark pieces are chopped into small granules. Then cork blocks are pressed from the granules, from which later thin slices are cut off. Very fine cork floors consist of these discs, which were additionally coated with a thin layer of natural cork. Very rare and extremely expensive are completely natural cork boards, but these are more used for fine wall coatings.

selection

Before work comes the idea of which variant of cork flooring you choose for your floor. Both the cork panels and the cork parquet have their own advantages. While you can choose from the panels, whether you prefer a floating installation, or whether the floor should be glued, with the cork parquet there is only the possibility to stick the individual cork tiles firmly to the substrate. The costs that you have to expect in each case for an example room of 30 square meters can be found below in our cost overview.

- floating floor can be taken along with the move

- glued floor usually better suited for underfloor heating

- Cork panels offer a variety of décor

- The substrate must often be prepared additionally for the bonded floor with leveling compound

- Cork parquet, depending on the seal, is also suitable for use in wet rooms

Instructions: Lay cork flooring floating

The cork panels must acclimatize to the installation room for at least 24 hours. For this purpose, the packages should not be opened, but kept only at normal room temperature there.

1. Lay down the impact sound

Even though cork is very flexible and has a good insulating effect, footfall sound insulation should always be laid under a floating floor. The cork in the panels is highly compacted and usually sealed with a decorative layer that would make the floating floor rattle with every step. By the way, your heating costs will benefit from footfall sound insulation.

The footstep plates are laid joint to edge and glued together. This does not have to be completely continuous, but only serves for anti-slip protection. You will have it much easier when laying the click panels. Under no circumstances may the footfall plates overlap.

Tip: Impact sound insulation is available both on the roll and as plates. The roles are usually a bit cheaper. However, they are also much thinner and brittle. Especially if there is also a smooth bottom underneath, the thin polystyrene rollers like to wander around. More effective and easier to work with are the mostly green footstools.

2. Lay cork panels

For a floating installation, a gap of about 1.5 centimeters must always remain at the edge of the floor towards the wall. All natural materials such as wood or cork expand in temperature changes something. The flooring made of cork panels would squeal when laid out to the wall. The edges are secured during the installation of the cork panels with wedges to the wall. This keeps the joint while laying the floor.

In the first row of cork panels you often have to make adjustments to the wall. If there are small protrusions or larger irregularities of more than five millimeters, you must transfer them to the first row and cut them out accordingly. The easiest way to do this is to click together the first row and put it on the wall. With a small spacer, you can then transfer the course of the wall to the row of panels.

Tip: To transfer the unevenness of a wall, the painting templates of your children are quite suitable. There are usually punched holes in which you can put the pencil. Otherwise, you can also make such a template simply from a small board by drilling a hole for the pencil at the correct distance.

3rd click function

The click panels are first carefully pushed together. This always happens in rows. If the panel with the spring is pushed into the groove of the previous row, the hammer on the other side is pushed over the groove and hit briefly with a rubber hammer. Then the panel clicks firmly in the previous row. Laterally, the click function is used as well. The side edge pieces on the wall are clicked into place with the pull bar instead of with the bat. The iron can also be hammered with a rubber mallet until you hear the click.

Tip: You can use the remainder of the laterally sawn panel as the starting panel in the next row. It should have at least a length of about 20 centimeters, since the panel can otherwise break out of the guide.

4. Theses

Mostly they have to adapt the last row to the wall. Here you proceed in a similar way as in the first row. You should also join the last row and then measure the distance to the wall. With the jigsaw, you can adjust the entire series. This series is also inserted with the train iron.

Tip: Use a matching skirting board that matches the decor of the cork panels. At the same time, many manufacturers offer skirting boards and matching apertures for pipe passages for every décor. If you have little experience with miter cuts, you should also buy the corresponding inside and outside corners for the baseboards.

Glue and seal cork parquet

The above click panels can also be glued over the entire surface, then of course no footfall sound insulation must be placed. When cork parquet, which must always be glued, there are again two variants, which differ slightly in processing. The one variant is already prepared for gluing on the underside, here only the substrate has to be coated with glue. For the other panels, the cork tile and substrate must be coated with adhesive. For this a special cork contact adhesive is used.

Tip: The cork tiles must also acclimatize. You should put the cork tiles in the room between 24 and 48 hours before gluing. Then turn on the heating there. If it is the living room, the room temperature during this phase should be calm 22 degrees. In a dormitory about 18 degrees should be created for the acclimatization.

1. Balance ground

Depending on the substrate, it must be prepared. Highly absorbent substrates must be provided with either a primer or a primer. An old tiled floor should be leveled with a leveling compound, otherwise the tile pattern will transfer to the surface. Other floors must always be thoroughly cleaned, dust-free and dry before cork tiles can be glued.

Tip: For a concrete floor, it may be necessary to apply a leveling layer of at least two millimeters to the substrate so that the adhesive can later set safely. So you need to know exactly which pre-treatment is recommended for your substrate in conjunction with the appropriate adhesive. If this can not be found in advance, you should first glue only a cork board and check after drying if the bond was sufficient.

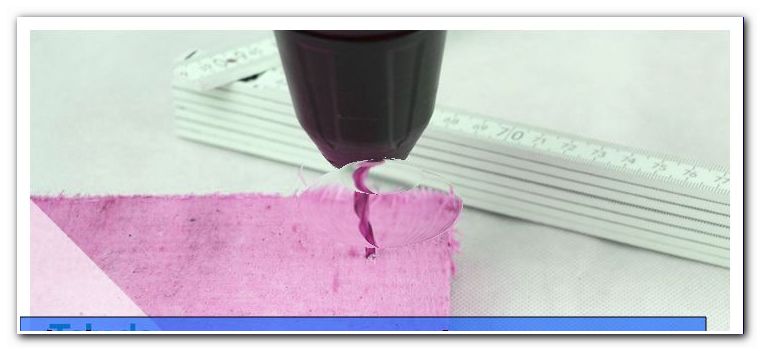

2. Glue cork boards together

Pre-glued cork boards are simply placed on a bed of cork adhesive and pressed with a rubber hammer or a small pressure roller. Depending on the manufacturer, either a short-pile velor roll or a toothed spatula is used to apply the cork adhesive.

Tip: Pay close attention to the instructions of the glue manufacturer. Some adhesives have to be left to air for a few minutes after application, while others need to be connected to the cork sheets immediately.

Cork boards that are not pre-glued must also have a layer of contact adhesive on the underside in addition to the cork adhesive on the substrate. These plates must also be firmly pressed or struck. Make sure that there are no joints and the panels are each at right angles.

3. Seal

Some types of glue cork must be sealed after installation. The special cork paint is solvent-free in most cases, but it has to be applied in three coats. Between the sealings is always a long drying time. In contrast to the sealing of a wooden floor, however, the cork parquet floor must not be sanded between the individual seals. In addition, the seal should be applied quite well with a velor role. Pay attention to the drying times and the curing times before the floor is fully loadable.

Tip: If you want to use the floor as quickly as possible, you should definitely buy end-sealed cork parquet. Then all you have to do is stick to the drying time of about a day. With the installation of the furniture but you should wait more three days until the glue is completely dried out. There is also a pre-sealed type of glue cork which requires only one coat of sealant.

Costs: Lay cork floor

The craftsmen usually demand hourly wages. This is depending on the region in which you want to have laid a floor for a carpenter between 15 and 40 euros. In large cities and in the southern German area you will probably find no trained carpenter under 30 euros per hour for the flooring. For the fully bonded floor covering, you can also entrust a carpet laying machine with the task. This is especially suitable as a complete package with the floor covering. In general, you should always ask for three offers from different craftsmen for a larger number of square meters.

- Select a craftsman according to the type of installation

- Check hourly wages, but if possible agree flat-rate

- Get three offers about costs for larger construction projects

- always work on account, otherwise there is no guarantee for the work

Tip: Many craftsmen want to know exactly what to expect and either check the material or buy it yourself. You should take this into account, especially if you have to settle for hourly pay. What you have then saved on the material, you spend otherwise again several times for the wages of the craftsman. Our tip is therefore always to include the craftsman in the purchase, because he knows the matter and has to deal with it every day. So you will find the best cork flooring for your purposes, which will last a long time.

Cost overview

Here is a small example of what costs you have to expect in each case. In our example, we have taken a large room of 30 square meters as a basis. Of course, in both variants, there are very significant differences in the prices that are required in the trade, so all listed prices are approximate.

Cost cork with click system

- Conveniently - 14 euros square meters - 30 square meters - 420 euros - with skirting board - 480 euros

- Medium - 25 euros square meters - 30 square meters - 750 euros - with skirting board - 900 euros

- High - 50 euros square meters - 30 square meters - 1500 euros - with skirting - 2, 000 euros

- Baseboards between € 1.50 and € 15 per meter depending on the quality of the floor

- Impact sound insulation about 2 euros per square meter - 30 square meters - 60 euros

- Small material complete for 30 square meters - about 10 euros

Costs of fully glued cork

The prices refer to already sealed cork. Unsealed cork was hard to find in the offers.

- Conveniently - 16 euros square meters - 30 square meters - 480 euros - with baseboard - 540 euros

- Medium - 28 euros square meters - 30 square meters - 840 euros - with skirting board - 1, 000 euros

- High - 65 euros square meters - 30 square meters - 1, 950 euros - with skirting - 2, 500 euros

- Glue - requires about 300 grams per square meter - 30 square meters = 9 kilos - containers with 5.5 kilos about 60 euros - floor complete 120 euros

- Small items - about 20 euros

Tips for quick readers

- Select soil type and adapt it to the purpose

- Floating cork panels with click system

- Lay out the impact sound

- Fit panel row one to wall

- Always secure the click system sideways with wedges

- Lay out the panels together

- fit last row of cork panels

- If necessary, prepare the floor with leveling compound

- If necessary, mix the glue

- Apply glue to the surface with a toothed spatula

- work off small areas - glue dries quickly

- Lay out cork parquet - press with roller

- Finally, roll again

- possibly seal cork surface

- ask for several cost estimates for installation