Tin roof - structure, prices and costs for laying

- Components of a trapezoidal sheet metal roof

- Advantages and disadvantages of a sheet metal roof

- materials

- Galvanized steel sheet

- aluminum

- copper

- stainless steel

- Assembly

- 1. Establish lower connection

- 2. Mount trapezoidal sheets

- 3. Theses

- Tips for quick readers

The trapezoidal sheet roof is much cheaper and faster laid than a tiled roof. In terms of leak-tightness, the roof made of folded rolled steel is in no way inferior to the fired clay tiles or slate shingles. Nevertheless, they have some disadvantages that do not make them suitable for any building.

Roof off the rolling mill

This text is about tin roofs, which are made of trapezoidal sheet metal. In addition to these very efficient covering methods, there are also normal roof tiles made of sheet metal. These hardly differ in their type of installation from the normal clay tiles.

A trapezoidal sheet is a multi-edged or roll-rolled sheet, which can cover several square meters at a time. If a high-quality sheet is used, it is as hard-wearing and durable as a normal tile roof. The roof profiles are available in numerous standard sizes, which make it visually suitable for every application. Even a simulated brick structure is today possible as a tin roof. This allows even demanding local building codes to be operated while choosing a very fast and economical solution for the roof. The cheapest form of roofing sheets is the famous corrugated iron. This is not very aesthetic and is usually used only for garages, arbors, carports or extensions. As a house cover they are only technically suitable. The local building regulations do not usually provide for the use of corrugated iron roofs.

Components of a trapezoidal sheet metal roof

A roof made of trapezoidal sheet metal consists of:

- standardized trapezoidal sheets in the ordered length

- individually folded eaves sheets

- domes

- special screws

- gutters

- Gutter brackets

- individual entrance panels

- individually edged ridge sheet

- Profile filler made of rubber

The trapezoidal sheets form the actual roof skin. They make up the majority of the roof covering.

The eaves panels sit on the sides of the roof, just above the gutter. Their task is to reliably guide the rainwater draining from the roof membrane into the gutter.

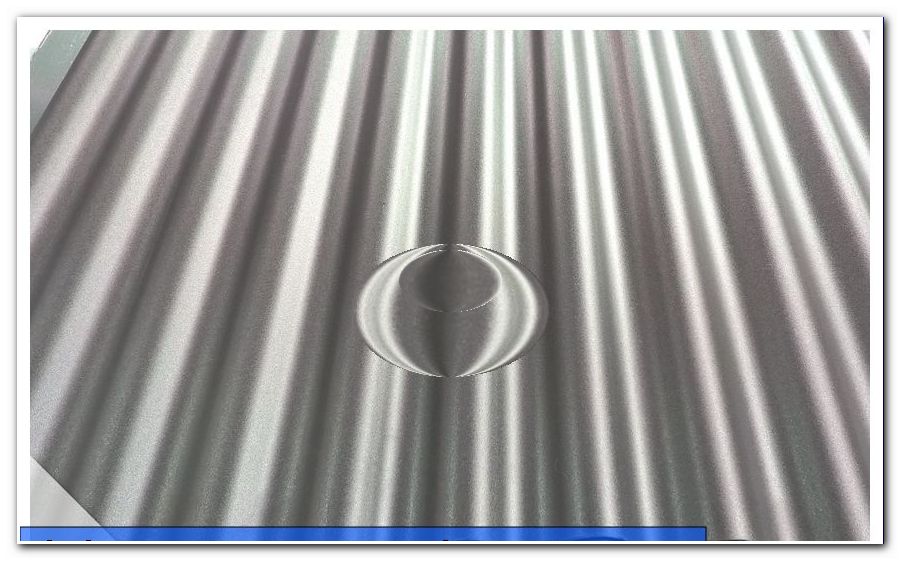

The calottes are the underlay for the screw connection. They ensure that the compressive force is evenly distributed over a large area, so that in strong wind, the sheet can not tear at this point.

As a screw connection, special bolts for trapezoidal sheets are recommended. Although they look like long wood screws, but have a sharp point. These facilitate the drilling through the sheets considerably.

The gutters direct the rainwater into a downpipe. There it can be forwarded to the sewage system. Alternatively, a cistern in which the rainwater is collected is suitable at this point.

The verge sheets form the lateral conclusion of the roof skin on the roof slopes.

Finally, the ridge sheet is the top of the roof. The profile fillers are used wherever a metal sheet is overlapped by another one. This is above all the point between trapezoidal sheet metal and eaves sheet metal and between ridge sheet and trapezoidal sheet metal.

Advantages and disadvantages of a tin roof

A tin roof has the following advantages:

- Very fast installation: A sheet metal roof covers several meters at a time with each work step. The large modules give the roof a very special wind stability. The prerequisite for this is a sufficient number of glands.

- Good tightness: A sheet-metal roofing membrane is as dense as a roof made of slate or slate.

- Customizable: Today, there is a very large selection of colors and structures.

- Inexpensive (depending on the material): Trapezoidal sheets are already available from 7 euros per square meter.

- easy to assemble and well suited for DIY applications, as well as large light paths

But you have to consider the following disadvantages:

- the installation of a metal roof must comply with local building codes

- uninsulated is a tin roof in the rain very loud: We therefore advise against using it for roofs, under which a living room should be set up.

- Despite the best materials, a tin roof can rust after some time, as well as tarnish.

- Tin roofs are (except for stainless steel) very sensitive to pressure.

- The metal makes the tin roofs temperature sensitive. In the summer they heat up a lot, but in winter they form a big thermal bridge. If the tin roof is not used for a little-used warehouse, then it has to be insulated with great care.

Corrective action is taken here, for example, by trapezoidal sheet metal modules with integrated thermal insulation. They offer a very fast and cost-effective option for an optimally insulated roof. Their installation is almost identical to that of normal trapezoidal sheet laying.

A tin roof is by no means always a "cheap solution". If high quality copper is used instead of normal steel sheet, then the house gets a particularly noble appearance.

materials

Be sure to use high quality materials for your tin roof! If you are offered cheap trapezoidal sheeting, then stay away from it! You have nothing of it, if you have saved properly during the roofing and the roof is rusted away after two years!

For tin roofs, three metals have proven themselves, which have distinguished themselves by their good endurance properties:

Galvanized steel sheet

The standard material for trapezoidal sheet metal roofs is available in many different profiles. They are already supplied as galvanized sheets in the press shop and thus guarantee a good rust protection. In addition, a tin roof can be coated in any color. A weak point, however, arises during assembly: as soon as a trapezoidal sheet is pierced, it loses its protection against corrosion at the site. This is especially true when screws are used that do not match the metal of the roof. The cost of materials for roofs made of galvanized sheet steel is about 7-10 euros per square meter. Instead of galvanized sheet steel also very durable Titanium zinc sheet is often used. It costs about 20 euros about twice as much as normal galvanized steel. Due to the high price of titanium zinc sheet is usually used only for the eaves panels. Where the water can stand, sufficient high-quality material should be used.

aluminum

Much less frequently aluminum is used for tin roofs. This is less the price, but the softness of the material. Rolled aluminum is extremely sensitive to scratches and knocks. Aluminum is guaranteed to be rustproof, even at its attachment points. In addition to the normal coatings of lacquer or plastic powder, the aluminum foil is also the most aesthetic anodizing available. This method creates a noble glow, which gives the house a particularly high-quality impression. However, the anodized surfaces are also particularly sensitive to scratches and can then hardly be improved. Aluminum trapezoidal sheets cost between 30 and 40 euros per square meter.

copper

The copper is the king of tin roofs. Where normal steel sheet roofs are always a bit cheap compared to the tiled roofs, copper is a particularly noble variant. With about 100 euros per square meter, it is also not very cheap. The beautiful copper gloss loses the roof, however, quite fast and starts with a greenish patina.

stainless steel

Occasionally, stainless steel is also used for the roofing. However, this is an extremely expensive option. The material is very difficult to press in shape, which is why it causes the high cost. However, it is a very durable and consistently aesthetic solution. Especially brushed stainless steel is very resistant to scratches. In addition, stainless steel is very stable. In addition, it is particularly suitable for receiving roof structures such as solar thermal or photovoltaic modules.

Assembly

Mount a tin roof

The prerequisite for a tin roof is a load-bearing roof truss with battens. The purlins of the roof truss bear the load and carry it off into the load-bearing walls of the house. The battens provide leveling and sufficient attachment options. A tin roof can not be built "on the spot". Each roof must be individually planned and manufactured. This is especially true for the ridge sheet: It must have exactly the angle of the roof pitch, otherwise it can not be mounted afterwards.

Roof pitch is particularly important for sheet metal roofs: standing water is very dangerous for this type of roof. It quickly form rust nests there, which can hardly be eliminated. That is why a roof made of sheet metal is not suitable for a flat roof or a very slightly pitched pent roof. The minimum gradient for a sheet metal roof is three percent. However, every roofer will recommend an absolute minimum gradient of five percent. From five percent, a roof is considered "self-cleaning". Overlying dirt, such as leaves, dust or bird droppings will be reliably rinsed off during the next downpour.

The following tools are required for mounting a sheet metal roof made of trapezoidal sheets:

- Hand-Kantzange (about 18 euros)

- Powerful cordless screwdriver (about 150 Euro)

- Ruler, pencil

- cut-resistant gloves (about 5 euros per pair)

1. Establish lower connection

The gutter holders are milled into the ridge beams with a milling cutter and mounted. The gutter is then inserted and fixed by the bending of the tabs on the gutter bracket. Above it comes the eaves. It is firmly nailed to the purlins or screwed. Above this comes the profile filler made of foam rubber.

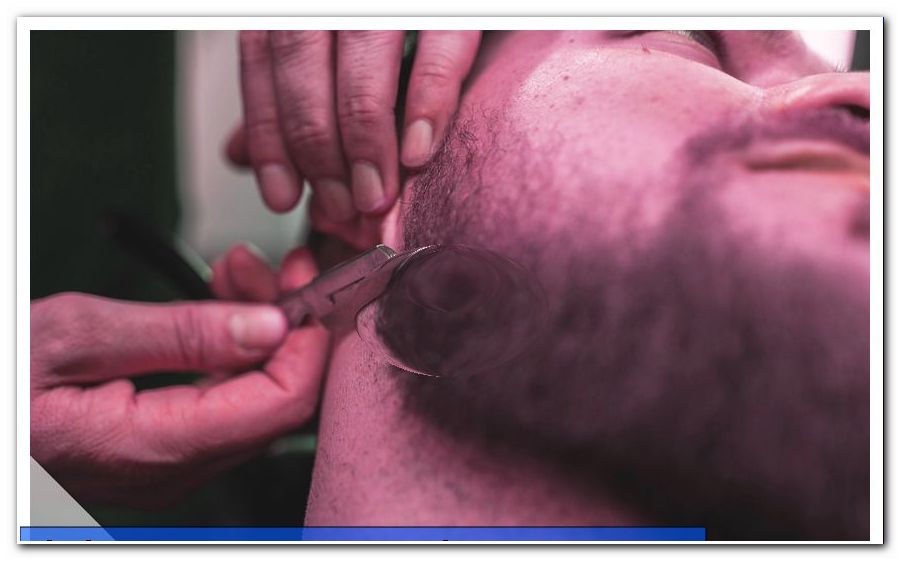

2. Mount trapezoidal sheets

Now the trapezoidal sheet is mounted. It has to protrude slightly above the gutter. When mounting the trapezoidal sheets, do not forget the calottes! The mounting screws can otherwise tear and the roof will be covered in the next storm. The trapezoidal sheets are machined after complete screwing with the square tongs. At the bottom, the edge is bent vertically downwards. So the water runs reliably into the gutter. At the top, the sheet is bent vertically upwards. This prevents wind from pushing up the water and into the roof. Then the upper profile filler is mounted.

3. Theses

The ridge sheet is laid on and fastened. Subsequently, the slopes of the roof are covered with the local aisles. This means there is no chance of rain falling on the side to penetrate the building.

Do it yourself or have it done "> Tips for quick readers

- Brick modules as sheet metal roof profiles are generally accepted

- Trapezoidal and corrugated roofs are mounted very quickly

- Always pay attention to safety, especially with sharp metal sheets

- Use only special screws - this facilitates the work afterwards and prevents rust damage