Stick Plexiglas correctly - glue acrylic glass waterproof

- foreknowledge

- UV adhesive

- Original Plexiglas adhesive

- Solvent adhesives

- Reaction adhesives

- superglue

- Alleskleber

- Adhesives for aquariums

- dyes

- acetone

- Avoid dangers

- Glue Plexiglas

- preparation

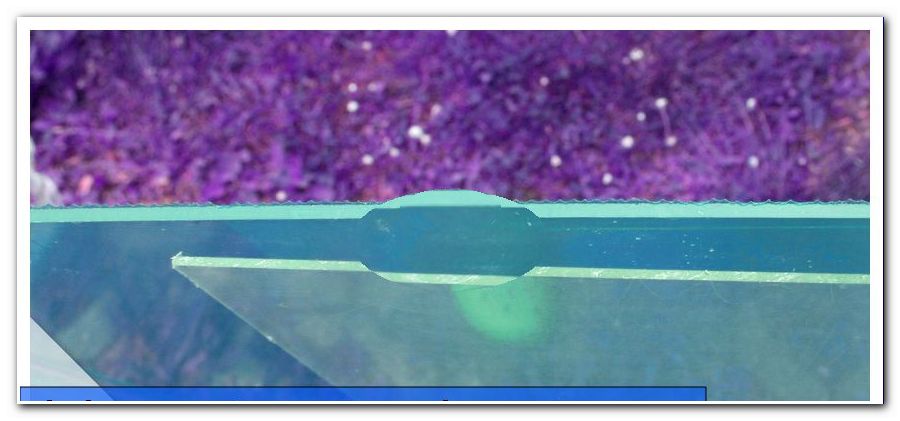

- Glue acrylic glass on acrylic glass

- Glue acrylic glass on other materials

- Prepare edges

- Costs for bonding

- Tips for quick readers

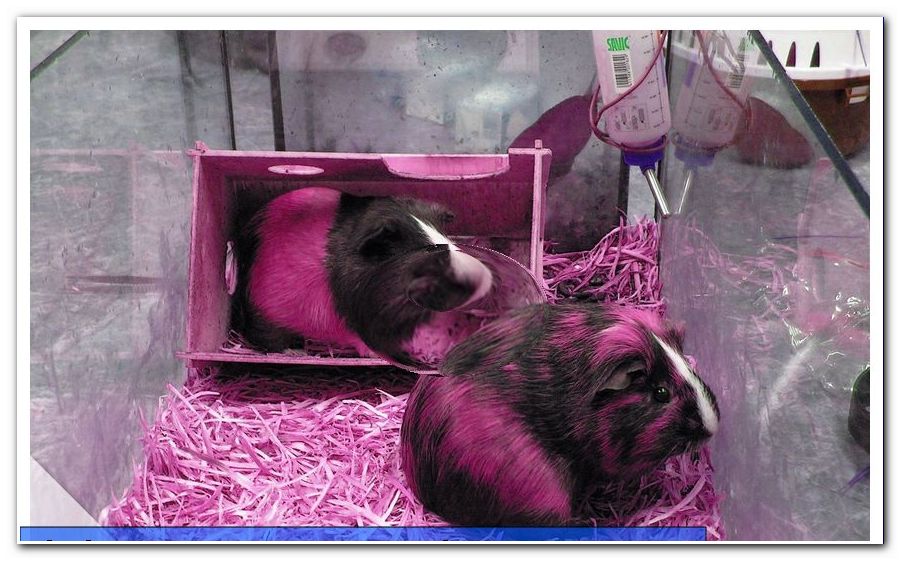

Plexiglas is one of the popular building materials because it is very similar to optical glass panels. However, the material is unbreakable and thus less sensitive than glass. It is therefore often used as a substitute for glass and can be used in the form of window panes or for aquarium construction. But how do you glue the plates together or on other fabrics ">

The acrylic glass can be either transparent or colored variants. The adhesive surfaces can also be seen later or hidden. Since the material has a smooth surface and conventional adhesive does not retract, it is important to pay attention to the choice of adhesives and to work precisely. Applying too much adhesive will cause smudging and the result will be messy. Errors when cutting the plates are now noticeable. It is also a particular challenge to glue the boards watertight. You have to work very carefully and avoid transitions. Find out which way of working is ideal for this.

foreknowledge

Acrylic glass can be glued waterproof and is therefore a valuable building material for various projects. During processing, you must observe the material of the surface. For example, there are differences whether you want to put Plexiglas on Plexiglas or wood. Therefore, when selecting the adhesive, make sure which materials it is suitable for. Particularly waterproof are adhesives based on silicone. Common adhesives include:

UV adhesive

It is usually offered where you can buy acrylic sheets. Buy the glue together with the plexiglas sheets, then you can be sure to find a suitable product.

Tip: Apply the UV adhesive as a thin film, then it remains invisible after curing. The more evenly you apply the layer, the greater the waterproofness. Unevenness is the height to ensure that gaps form, through which moisture can penetrate.

Original Plexiglas adhesive

ACRIFIX® adhesives are considered to be exceptionally durable and waterproof. They are suitable for gluing Plexiglas on Plexiglas and are available in different versions:

Solvent adhesives

Solvent adhesives consist of a mixture of different solvents. They dissolve the surface to be bonded, causing the polymer chains to swell. As a result, they can get caught up with each other. The solvent escapes through evaporation or transfer into the substrate from the adhesive and the polymer chains contract further. This creates a good adhesion of both materials. The biggest advantages of solvent adhesives include fast strength and suitability for outdoor projects. The transitions between the assembled parts are waterproof.

Important: Evaporation of the solvents produces vapors that must not be inhaled. Wear appropriate protective clothing such as respiratory protection during processing.

Reaction adhesives

ACRIFIX® adhesives are available in the form of reaction adhesives. They are manufactured on the basis of MMA / PMMA. These are polymerization adhesives that are offered as one-component adhesives and as two-component adhesives. Depending on the exact variant, the adhesives may cure, for example, when light or UV radiation acts on them. Or there is a hardening by the addition of a catalyst instead. One of the biggest advantages is that you could use these adhesives on large surfaces. In addition, the substances are gap filling. After sufficient curing, these are weather-resistant and high-strength compounds that can withstand heavy loads.

superglue

If the bonded area is no longer visible later, then you can also use super glue for bonding. It is important that the selected model is suitable for the two materials to be joined together. To achieve high water resistance later, you can then use silicone to form a joint over the transition. It should be noted, however, that superglue is mainly suitable for smaller areas indoors. The adhesive is made of cyanoacrylate and is not temperature and moisture stable. However, it is suitable for making a first connection, which is liable within a very short time. Subsequently, a further processing can take place. In addition, can be achieved in craft work for indoor very good results.

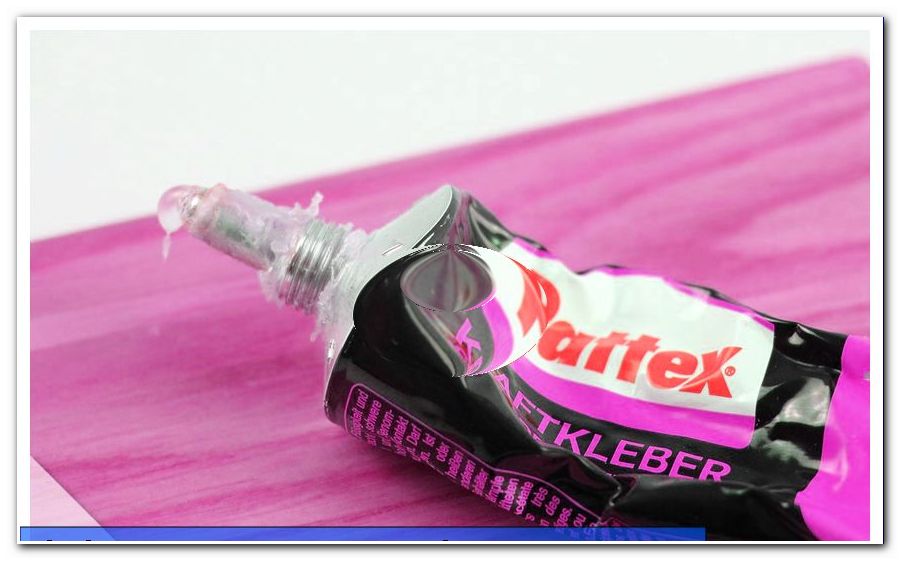

Alleskleber

An alternative to super glue is all-purpose glue. However, it should also be used only where the adhesive is not visible because it does not become "invisible" after curing. Its advantage is that the acrylic glass is easily dissolved and thus the adhesive cures quickly.

Adhesives for aquariums

You would like to build an aquarium or the components will later be close to food, children or animals ">

dyes

Many adhesives, such as the ACRIFIX® adhesives, can be treated with special dyes. This allows the color to be selected and adapted to the environment. They realize the construction projects as desired, without the adhesive used being noticeable afterwards.

Tip: If you use a colored adhesive, you must take extra care to ensure that you are working properly, as it is difficult to remove glue stains.

acetone

Acetone is a solvent which is also often recommended for gluing the plates. However, it dissolves plastics, which leads to changes in the material. The basic principle of acetone is the softening of the edges, so that a bonding and bonding takes place with each other. However, you must be aware that the appropriate remedies have health risks and therefore may only be used with appropriate protective clothing. High doses can be narcotic and thus life-threatening.

Avoid dangers

The adhesives are effective and effective adhesives. These, however, develop fumes, so inhalation must be avoided. It is best to wear a surgical mask while working, and to ensure adequate ventilation during and after the bonding process. Since the same substances are already used for cleaning, you also have to do this

Observe safety measures. Contact with the skin and eyes must also be avoided. Gloves and long-sleeved clothing are therefore recommended. After processing, you must store or dispose of any leftovers.

Glue Plexiglas

preparation

- First you have to clean the acrylic glass, so that the glue can adhere optimally.

- Since hardly any dirt can adhere to the surface of the non-porous material, it is easy to dust off the plates first. Take some water with dishwashing detergent and wipe the surface with a damp cloth. The cloth should be soft and lint-free to prevent scratches. Dry cleaning is not recommended as it can also cause scratches.

- If there are stronger, such as greasy, dirt on the plates, then use benzine-free gasoline for cleaning.

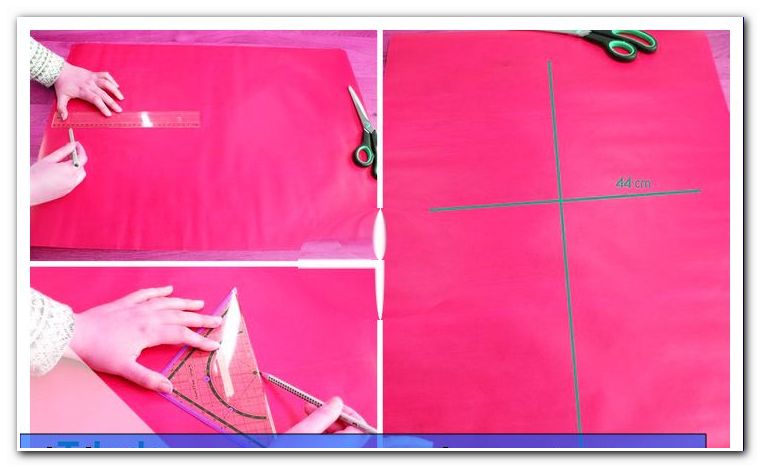

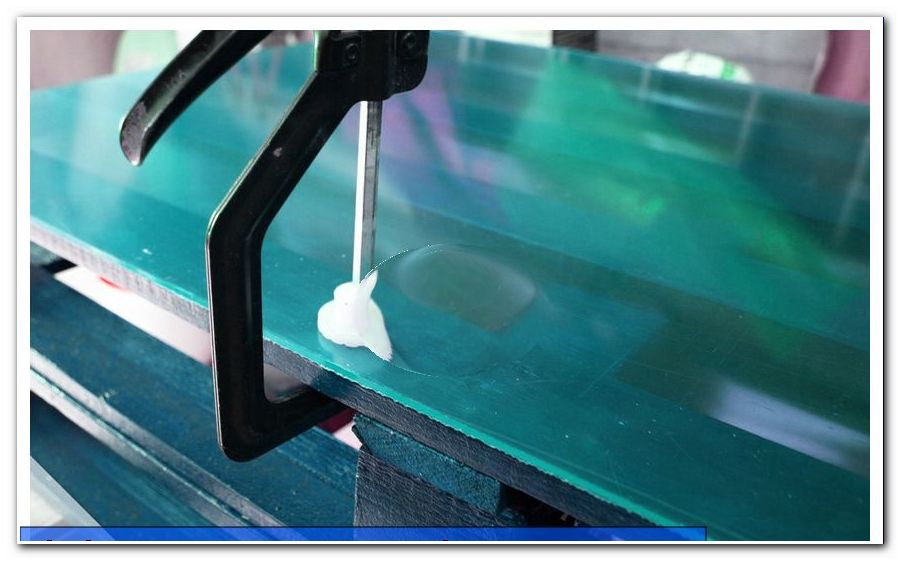

Glue acrylic glass on acrylic glass

In this case it is best to use the ACRIFIX® 1S 0116 or a suitable all-purpose adhesive. The ACRIFIX® 1S 0116 is especially suitable for dyed material.

Tip: It is important that the edges are perfectly fitting and flat. Only then is an exact way of working possible, which leads to a watertight gluing.

1. Clean the adhesive surfaces again briefly before the gluing process and allow them to dry sufficiently.

2. Apply the adhesive to the surface. Particularly useful is an agent that is purchased in a tube, since the amount can be optimally dosed.

3. Immediately join the parts to be glued. To prevent them from slipping, fix them with tape or some other means.

4. After about 1 to 2 hours, the first adhesion should be sufficient. Now you can handle the parts. The final curing is given only after several days.

Tips for choosing the right glue

- When it comes to colorless acrylic glass, the ACRIFIX® 1R 0192 is a good choice. Apply the glue directly from the tube. It is filling and can be cured by daylight or fluorescent lamps.

- If you only need to join smaller parts together, cyanoacrylate-based superglue is suitable.

Tips for bonding

- Make sure that the parts to be bonded are free of tension.

- The adhesive or its vapors should not penetrate into cavities. This could lead to cracking.

Glue acrylic glass on other materials

If you want to glue acrylic glass on other materials, then this is possible with many materials, such as metal, stone or glass. For this purpose, especially elastic adhesives are suitable. They can be silicone-based. Popular adhesives are ACRYLGLAS SILICON 400 and Otto Seal S 72.

Tips

- When selecting the adhesives and the application, pay close attention to the manufacturer's instructions and, if necessary, use adhesion promoters. Silicone rubber or the corresponding vapors must not get into cavities in order to avoid the formation of cracks.

- Moreover, do not apply silicone rubbers to tensioned or cold-bent PLEXIGLAS®. This can lead to the formation of tension.

Method:

- The adhesive surfaces must be cleaned, dust-free and dry.

- Limit the detention zone strongly. You can use adhesive strips for this.

- If recommended by the manufacturer, treat the edges or surfaces with adhesion promoter.

- Fix the parts to be glued.

- Apply the silicone rubber with light pressure.

- Use a moistened tool and smooth the adhesive surfaces.

- Pull off the boundary strip so no skin can form over it.

- Let the adhesive harden sufficiently. The exact time depends on the selected adhesive and can be read in the manufacturer's instructions.

Prepare edges

After you have cut the plexiglas sheets, it is often necessary to work the edges before gluing. Grinding and polishing give you a smooth surface, so the parts can be put together optimally.

1. grinding

- Always sand wet. This prevents thermal stress in the material and the friction surfaces are protected.

- Perform the grinding process in 3 stages. First, use a coarse grain size (80 to 240). This is followed by a medium grain size (400) followed by a fine grain size (600 to 1000).

2. Polishing

- For polishing, use pastes, waxes or a classic car polish. Make sure that the fabrics used are very soft.

- Then remove the polish and clean the edges with benzine. It is important to provide adequate ventilation, avoid skin contact and eliminate fire hazards.

Remove edges and deburr

If it is milled or sawn cut edges, you can deburr and smooth them with a machine file or a scraper blade.

The profiling of the outer edges

With a profile cutter with ball bearings, the edges are brought into the required shape.

The right workmanship

To prevent stress from building up after processing, which leads to damage, you must determine the optimum board dimension. Plan for this a sufficient heat and moisture expansion game. If you want to install the panels waterproof indoors, then you should consider 3 mm game per meter length and width.

Make a note of all planned blanks in advance. Do not remove the surface protection. Mark the cut edges only on the slide.

Costs for bonding

The ACRIFIX ® 1R 192 is available in the 100 gram tube for around 7 euros. It is a very rich product, so the cost of the glue is considered low. Just when only edges are glued together, the tube is sufficient for several meters. However, prices generally only apply to tube adhesives. For example, if you want to use a cartridge equipped with a spray tip, the cost will increase. The advantage is that you can apply the adhesive precisely in the desired amount. Here are the prices for 100 millimeters at around 20 euros. Even products from other manufacturers are in similar price ranges. Acetone is cheaper and already available for 4 Euro per 250 milliliter bottle.

Adhesive: 7 euros per tube

Car polish for the preliminary work: 15 Euro (Since only a little of it is needed, the remainder can be used elsewhere.)

Cleaning agent: 10 Euro (Again, only little is needed)

Towels: 1 Euro

Tip: Often, large towels are cheap to buy and can be tailored.

The costs seem high at first glance, however, depending on the surface to be bonded, only a small amount is needed so that the cleaning agents and the polish are not completely used up.

Tips for quick readers

- ensure smooth edges

- clean the plates sufficiently

- work without tension

- plan sufficient tension space

- Make sure you have adequate ventilation

- wear protective clothing

- Use silicone-based adhesive

- Silicone adhesives are especially waterproof

- Acetone possible

- Use adhesives from the manufacturer of the panels

- fix the parts when gluing

- cure well

- for blanks, mark on protective foil