Make strip foundation for base plate in only 7 steps

- Calculation and planning

- Quantities and purchasing

- Pour strip foundation in 7 steps

- Step 1 - stake out and measure

- Step 2 - Dig the foundation trench

- Step 3 - shelling the foundation

- Step 4 - Prepare steel

- Step 5 - Mix cement

- Step 6 - Add mixture

- Step 7 - Peel off and smooth the foundation

Whether for the garden shed, a garage or your own home, under the floor slab of the building belongs a stable strip foundation. If the bottom plate is only placed in a sand bed, the plate can break later. How to easily concretise the strip foundation itself, we show here.

If the strip foundation is for a larger base plate, for example when building a house, then you should create it in a ring shape and possibly pass further strips under the plate. So the loads are discharged evenly into the ground. Cracks or breaks in the plate do not arise at all by this measure. To concretize a strip foundation for the bottom plate is not overly complicated, however the foundation must be put on frost-free, that means you have to go about 80 centimeters deep into the ground. Here is the detailed step-by-step guide to your strip foundation.

You need this:

- hammer

- Spade, shovel, wheelbarrow

- Ruler, guideline

- Sheathing boards, slats, pegs

- spirit level

- bucket

- Trowel, leveling plate

- Mason's bucket / blender

- Sand, gravel, cement

- nails

- Reinforced steel mesh / iron

Calculation and planning

A strip foundation must usually be only about 20 to 30 centimeters wide, but should in any case protrude below the frost line into the ground. Therefore, a depth of the foundation of at least 80 centimeters is actually recommended everywhere. In addition, you must pay attention to the size of your base plate. A base plate can not be transferred arbitrarily far and should therefore be intercepted in addition with another strip in between at large widths.

Of course, their individual strip foundations must all be the same height. If these are not connected to each other, you can use a long straight board and the spirit level to check that you have applied the strips correctly. Of course, that works better with a laser spirit level, which already exists for a few Euros in every hardware store and in the network.

Safer you go with a ring foundation. This is usually not really ring-shaped, but rectangular or square. Basically, the ring foundation consists of at least four strip foundations, which are connected to each other at the corners.

Quantities and purchasing

If you want to mix the concrete for the foundation yourself, you should know in advance how much cement and how much sand you will need later. Therefore, you should first calculate the cubic meter of the required cement mixture as roughly as possible. The length of the foundation must be multiplied by the width and depth of the foundation. Keep in mind that there is always some mixture going on and therefore add up to a certain reserve of about ten percent.

Example:

Foundation 10.00 m long x 0.20 m wide x 0.80 m deep = 1.6 cubic meters of cement mixture

So you can also estimate whether it is even possible to produce the entire mixture in the short time itself. The above example is still to be realized with a small cement mixer, as many do-it-yourselfers own it. But for a significantly larger amount, you should have the cement mixture supplied by a concrete plant. Keep in mind that the complete mix must be poured into the formwork within a relatively short period of time. Otherwise, the concrete will bind off before the complete mass can be filled.

Pour strip foundation in 7 steps

Step 1 - stake out and measure

Measure the position for the foundation exactly. If only one strip is to be concreted, then you can cut a peg at the beginning and end of the foundation and mark a strip in between. However, if you actually want to use the foundation for a floor slab, you should mark each of the four corners with a peg. If the floor slab is delivered in one piece by a contractor, you should make sure that you concretes the foundations really wide enough so that the slab does not stick out.

Tip: Tighten a string from peg to peg to keep the perfect direction during the excavation work. You should still check the angles with an angle corner, otherwise a trapezoid will be created instead of a rectangle.

Step 2 - Dig the foundation trench

It does take a bit of work and is tedious, but you should work relatively well and not dig up the digging foundation. Not only does this look unprofessional, it also costs you a lot of additional material. Therefore, the ditch should be kept as evenly wide as possible. If the earth is solid enough, you will only need to cover the top edge that protrudes from the earth later.

If you encounter rocks or extremely solid layers, you may even have to work with a hammer drill. Usually it is enough to use a hoe or a strong spade. The ditch must be 80 centimeters deep, so that your foundation can not be damaged by frost after concreting.

Step 3 - shelling the foundation

For a very soft floor, you need to make the shape of the foundation complete with formwork panels or sheathing boards. In order for the formwork panels to get enough hold on the sides, you should pile in pointed pegs here.

Tip: If you want to create strip foundations in a very sandy, loose ground, it is often not possible to properly excavate and encase the width of the foundation. Then you can build a foundation box out of the sheathing boards that you put in the ground completely.

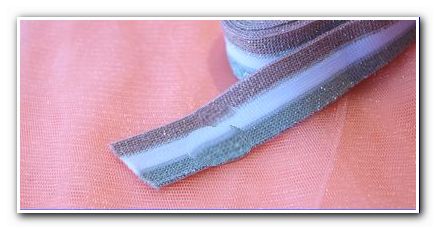

You should nail laths around the upper edge of your formwork panels, so that they are still stable when concreting. The cement mixture exerts strong pressure on the formwork panels, making sure that the panels are well nailed together. The border should be leveled immediately. Check with the spirit level again and again that the edges are straight. You should also compare the two sides.

Tip: For a sandy bottom, it is also recommended to cover the ground in the foundation pit with a little coarse gravel. However, the layer should not be too thick and evenly distributed.

Step 4 - Prepare steel

Cut the steel mesh mats into strips that fit well into the foundation trench. Bear in mind that the steel must not protrude from the concrete at any point. Otherwise the steel would rust and cause the concrete to burst. You should prepare the structural steel before concreting so that you have the steel at hand immediately. Of course you can also use slim iron for narrow foundations.

Tip: If you still have fractured concrete or clinker bricks from a demolition, you can later embed a small part of it in the foundation. This is handy if you use iron, because the stones provide a perfect distance between the iron bars. To do this, first fill in some concrete and then insert the stones or the break into the liquid concrete at a distance of about 20 centimeters. Then lay the monier iron horizontally and repeat this step about two more times.

Step 5 - Mix cement

Mixing the concrete is not so important for accuracy. It is enough if, for example, you fill in the running mixer with four blades of coarse sand and then a shovel of cement. Repeat this mixing ratio about three times. Depending on how much you have on the shovel, the machine is then filled to a third of a third. Gradually add water with the bucket until you have a creamy mass. After one or two blended mixtures, you'll figure out how much water you need for a mix.

Mixing ratio: normal concrete = 4 parts sand and 1 part cement - water as needed

Tip: A cement mixture can also be mixed to death. Then the water separates again from the mass and the concrete can not set properly later. So you should be very careful with the first mixes that all ingredients are mixed together, but still not let the machine run too long.

If only a small amount of concrete is to be mixed, you can do it directly in the wheelbarrow. Stir the sand-cement mixture in the cart several times before adding the water, then mix well with the shovel.

Step 6 - Add mixture

From the mixing machine, you can run the concrete directly into a wheelbarrow. So it's easy to transport the concrete. If you have a helper, you can keep the wheelbarrow slightly inclined while filling the mixture into the formwork with the shovel.

Slide about ten inches of mixture into the trench and spread it with the shovel. Then the structural steel is inserted. Make sure that the structural steel does not stick out of the foundation. On the structural steel, another layer of concrete is filled. Depending on how stable your foundation must be, up to three layers of steel mesh should be inserted at intervals of about twenty centimeters. So remains above the last layer of mild steel still a sufficient amount of concrete.

Tip: Take two or three iron bars and poke them repeatedly in the concrete during concreting, so that air bubbles are released and the concrete slips well.

Step 7 - Peel off and smooth the foundation

If the formwork has been completely filled with concrete, you must remove the mass top with a lath or a board. Check again the spirit level, if your foundation has not moved. With the trowel you should smooth the top a bit more. If bad weather is approaching or there are many trees around your construction site, you should protect the strip foundation from leaves, branches and rain.

Tip: After concreting, quickly clean all tools with plenty of water. Later, the concrete can not be removed. In a concrete mixer, you can fill some small stones with the water and then let it run. With the water and the stones, you can also rinse out stuck concrete residues.

Tips for quick readers

- Plan the size of the foundation

- Calculate quantities of sand and cement

- Stake foundation with stakes and string

- Check corners with angle

- Dig trench for foundation

- Line foundation trench with scarf boards

- bring some gravel to the foundation floor

- Cut the reinforcing steel mats

- Mix concrete mixture

- fill in concrete about ten centimeters high

- Insert mild steel mesh

- Continue to fill foundation

- possibly after 50 centimeters second layer of mild steel

- Completely fill foundation

- Peel off concrete and smooth