Step heights / stair dimensions to DIN 18065 calculate

- Increment in a staircase

- Determine raw construction dimension

- Calculation of the stairs

- Which stairs take "> Installation or shell stairs - advantages and disadvantages

A staircase is indeed a commonplace component. However, their production is very complicated and should only be carried out by professionals. In order to ensure consistently safe staircases in all buildings, their manufacture was firmly written in DIN 18065. An improperly built staircase is a very heavy Baumangel. As a client, you have the full right to dismantling and correct implementation. How to calculate and check a staircase, read in this text.

The natural stride length as a basis

The step rule is the most important formula for any craftsman involved in staircase construction. In addition to carpenters and staircase builders, these are mainly concrete workers and masons. Only a staircase made in the step rule complies with DIN 18065 and thus has the necessary security when going up and down.

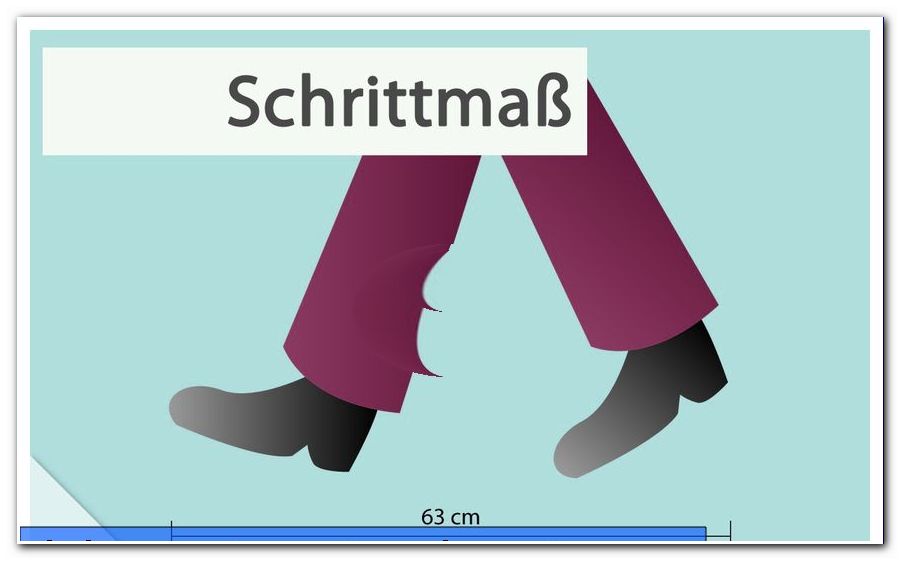

The basis of the step rule is the average stride length of an adult human. Although the body sizes of people with 1.60 m - 1.90 m form a fairly large spread in the average size, the step length remains relatively constant at about 61 - 65 cm.

Therefore, in DIN 18065 a step length of 63 centimeters has been defined as the average.

From this dimension build up the slope and the aspect ratio of a staircase.

Increment in a staircase

Stairs are designed to be accessed by a healthy, adult human. This means that one step usually takes two steps. This construction also allows the "Trippelschritt". This also allows elderly and handicapped persons to use a staircase. It is climbed step by step with both feet.

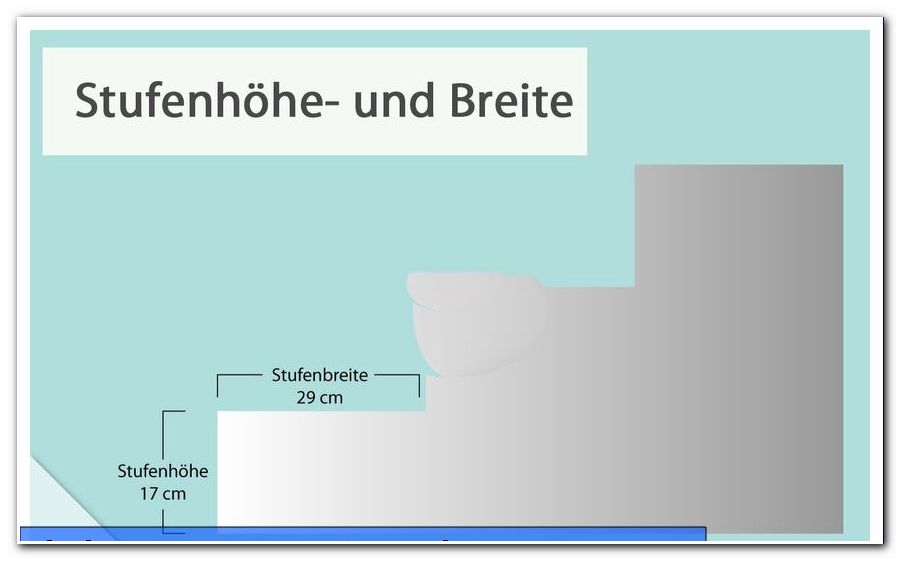

Starting from the average stride length, this must therefore be split into two gradients and one performance. A simple division by three would make the gradients and appearance equal. At 63 cm: 3 = 21 cm, however, it turned out that the steps are still a bit too steep and the appearance a bit too narrow to use the stairs comfortably. Therefore, the slope has been reduced by three centimeters and widened the appearance by six inches.

The standard size for a staircase is therefore:

- 18 centimeters per grade

- 27 centimeters per step width

In order to achieve more flexibility on site, however, this rigid requirement is extended by a slight variance. The step width or the appearance should be between 23 - 29 cm. Nevertheless, the sum of two gradients plus one performance must always be between 59 and 65 centimeters. That is why a variance is allowed, but this then compulsorily prescribes the dimensions of the other component. Therefore, these ratios are specified from step height to step width:

- 17/29

- 17.5 / 28

- 18/27

- 18.5 / 26

- 19/25

- 19.5 / 24

This measure can be found in all normal, straight or pedestal steps again. In spiral staircases rigid adherence to this measure has proved impractical. Therefore, a slight deviation from the standard measure is allowed for coiled or curved stairs.

Determine raw construction dimension

Now it is relatively easy to calculate the stairs in such a way that they make a permanent use possible. But there are still some traps lurking along the way. Basically, you measure from the upper edge of the raw floor to the upper edge of the unfinished floor of the next floor in order to maintain the degree of overcoming. The first mistake that can be made here is not to consider the thickness of the floor slab. Therefore: Always measure from top edge to top edge!

The normal room height in a detached house is at least 2.10 meters, but the rule is a measure between 2.20 and 2.50 meters. Room heights of only two meters or less are usually felt by the residents as depressing and uncomfortable, even if they are even much smaller than 2.00 meters. The thickness of a concrete false ceiling in normal family houses is between 16 and 20 cm. So you get a raw construction of 2.40 meters to 2.70 meters, which must be overcome by the stairs.

Calculation of the stairs

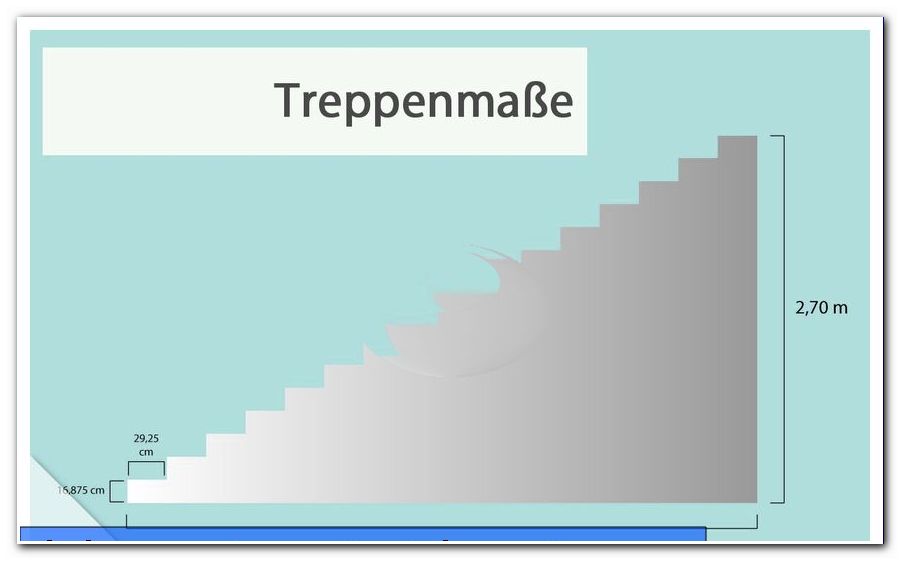

This measure can now be easily divided by the given standard heights for stairs. Starting from a clear bodyshell height of 2.70 meters, we arrive at a number of stages of:

270 cm: 17 cm / step = 15.88 steps

But since you never work with sub-steps, you now go from 16 levels at least. Now take again the clear shell height and divide it by the determined number of steps:

270 cm: 16 = 16.875 cm

This gives the height of a single step. With the aid of the incremental rule 2 x S + A = 63 cm, the width of the tread surface can now be calculated:

16, 875 cm x 2 + A = 63 cm

33.75 + A = 63 cm

A = 63 cm - 33.75 cm = 29.25 cm

However, since we now know that the finished staircase will have 16 steps and every step except the last one will have a width of 29.25 cm, the stair length can now also be determined:

15 x 29.25 = 438.75 cm or 4.39 meters

This length must have at least the stairwell to safely enter the stairs without bumping his head.

Raw construction is not finished measure!

This method is well suited for temporary built-in stairs or for retrofitted wooden or steel stairs. For concrete stairs, however, caution is required, because you can now very easily negotiate a construction error.

There is another factor added to make matters worse: The staircase must have the standard rules in the final state of installation, not already in the shell! As a rule, both the floors and the stairs themselves are still occupied, so that all height conditions change. For example, if the lower floor of the storey is fitted with a screed with built-in heating and the upper one has a strong floor insulation, then all the dimensions are no longer correct. Also, a coating of the stairs with thick marble slabs results in different step heights than a thin coating of tiles or PVC. It is therefore important to know in advance exactly how the stairs and floors are to be occupied. The height of the coverings must be included in the calculation of the stairs. If you forget only one factor, the staircase will be constructively so wrong that usually only a deconstruction is possible. A single step that is too low or too high makes the entire stairway very unsafe and becomes a constant source of danger.

Which stairs take ">

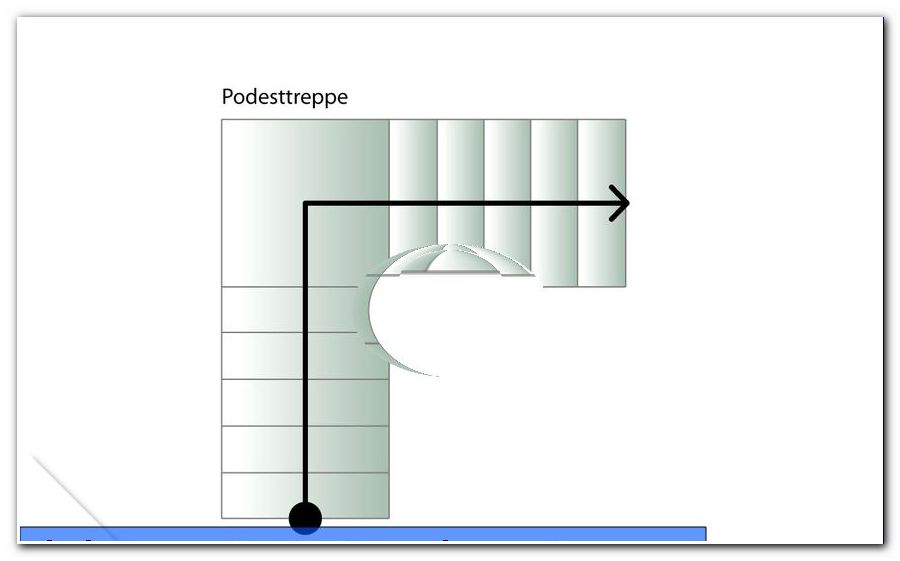

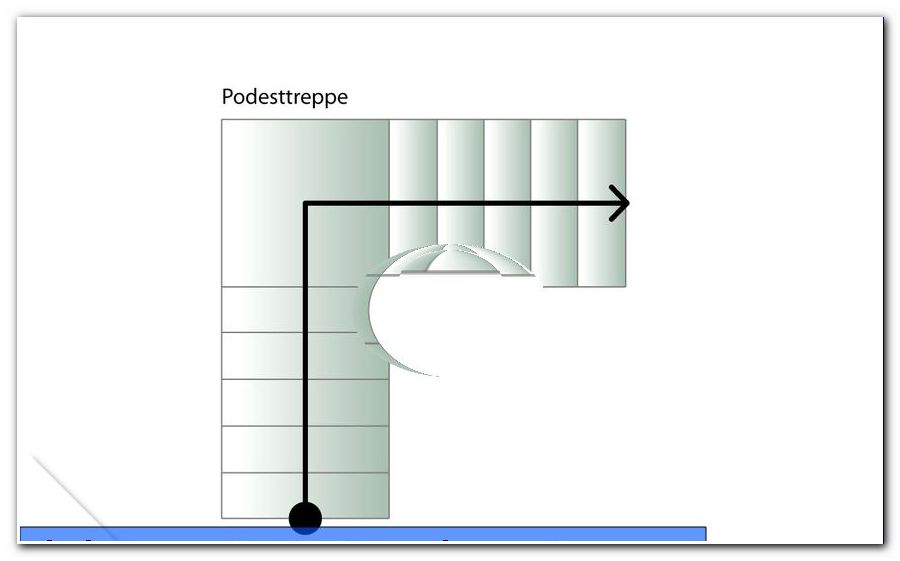

Half-turn staircases allow straight stairs to change direction. Usually a change of direction of 90 ° or at right angles is carried out. If a complete change of direction of 180 ° is to be carried out, the pedestal steps are altogether more recommendable. It is considerably easier to build and offers much more space when transporting loads.

Would you like to know more about the different types of stairs "> Overview of the staircases

Installation or shell stairs - advantages and disadvantages

The standard in single and multi-family houses is the occupied concrete staircase. This also fulfills static tasks. It is anchored to the floors with heavy irons and gives the house an additional stability. However, their installation is quite complex: If no concrete prefabricated staircase is used, it must be calculated, turned on, reinforced, poured and then switched off again. Later, it is still coated so that it fits visually and functionally to the rest of the house.

A subsequently installed staircase gives a much larger design variety. It does not always have to be the standard wooden staircase by far. Today's staircase builders can also make marble stairs for retrofitting. Nevertheless, the retrofitted stairs never reach the stability of a concrete staircase that is firmly anchored to the shell. Static tasks can hardly take over the subsequently installed stairs. But their calculation is much easier. In addition, even subsequent changes to the building are much easier to implement. An unscheduled underfloor heating together with a thick insulating layer always creates an irregularity in the incline of concrete stairs. In a built-in staircase, the stairs can either be replaced or easily adapted.

Pricing, however, it depends very much on the execution, which solution is cheaper. A pure concrete stair prefabricated section with 15 steps costs at least 1200 euros. There are also decking and railings, which can quickly more than double the price. Another important factor in concrete staircases is the proper coating: If the steps are laid without a floating screed, every flight of stairs in the entire house becomes audible. This too can lead to a tree-dangle, in which a correction can be demanded. A built-in staircase is indeed priced similar. However, it is usable immediately after installation. A handrail is usually installed.

Conclusion: Well planned costs are saved

With hardly any other component, you can make as many and momentous mistakes as with a staircase. A measure calculated incorrectly and the staircase must be completely rebuilt. Corrections are very difficult to implement and usually lead to unsatisfactory solutions. That is why good and sustainable planning is the most important thing about a staircase. All factors must be taken into account, including potential later installations. But if you take enough time and expert advice, the staircase becomes a reliable, shapely and functional part of the house.