OSB boards information - all strengths, dimensions and prices

- OSB panels - features at a glance

- Adjust the size of the plates

- Prices for chipboard

Choosing the right material is critical to success in construction. Coarse particleboard differ in quality, size and strength. In addition, a subdivision into different EN standards takes place. Read what matters for the prices and selection and how to find the right OSB disks.

Coarse particleboard is very different in terms of dimensions and price. Since they are used on walls, on floors as well as for cladding and drywall, they have different properties. When choosing, you must pay attention to a few points in order to obtain the required OSB boards at a low price. These are subdivided into different categories so that you can see the application areas at a glance. The prices depend on various factors and are stated either per plate or per square meter. Read about the differences in the individual plates.

OSB panels - features at a glance

OSB boards are available in different thicknesses, sizes and finishes. They are available with a water-repellent surface, can be plastered and are extremely dimensionally stable. Possible applications are the drywall and the interior lining.

Choose the right thickness and weight

On the market, the chipboard is available in different thicknesses. The spectrum ranges from thin versions (around 6 millimeters) to plates with a high thickness (over 40 mm). When choosing the thickness, make sure that the plates are used for different applications. If they serve only as optical cladding, then low strengths are sufficient. In drywall, however, stronger variants are selected. The weight depends on the thickness and must also be considered.

The division of the coarse chipboard according to the standard EN 300

The EN 300 standard divides the chipboard into different categories. The subdivision is based on the moisture resistance and the mechanical properties. This allows you to select the appropriate category for the plates at a glance. The higher the category, the more resistant the panels are to moisture and stress. There are four categories:

- OSB / 1: The chipboard panels are used for interior fitting in the dry area. In addition, they are used in the field of furniture.

- OSB / 2: The chipboard can be used in dry construction for load-bearing purposes.

- OSB / 3: The chipboard panels are used in the wet area for load-bearing purposes.

- OSB / 4: The chipboard panels are particularly durable and are used in the wet area for load-bearing purposes.

Adjust the size of the plates

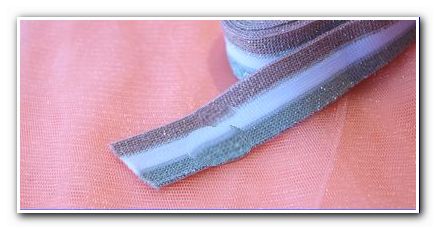

The size of the plates will usually be in millimeters. The details refer to the length and the width. It is important to note that both straight edge and tongue and groove models are available. The latter are often used when laying on the ground and have a stable connection with each other. The panels should be as large as possible when covering the walls to reduce the length of the joints between the panels. Intermediate scratches are weak points, which can lead to a shift of the plates among themselves, for example.

If you are planning a plastering of the coarse particle boards, then working with large panels will be easier. At the transitions, it can lead to the formation of cracks in the plaster, which is why the joints must be treated separately. However, the plates have a certain weight, which in turn smaller plates are beneficial. These are easier to handle due to their low weight. For interior fitting, you can also work with plates of different sizes. It is important that you pay attention to a consistent strength.

Tip: The thickness and size specifications allow for certain tolerance ranges. Therefore, coarse particle board with the same values can have different properties. By buying all the plates from the same manufacturer and at the same time you reduce the risk of a different thickness or size.

The strength determines the insulating effect

Serve the plates of insulation, then the effect depends, inter alia, on the strength. The thicker the material, the better the insulating properties. With special treatment and additional plates, you can further enhance these properties. As far as possible, coarse particle board should not be laid over underfloor heating, as this can lead to warping or shifting due to the temperature differences and the heat.

The chips contained

The chipboard is made from individual chips that are glued and pressed. The pressing temperatures are between 200 and 250 degrees. The chips themselves have a length of 100 to 200 millimeters. They are also 10 to 50 millimeters wide and 0.6 to 1.5 millimeters thick. They arrange themselves in the material crosswise in three layers.

The adhesives used in the coarse particle board

The chips are connected with a special adhesive. Here, PF adhesives, PMDI adhesives or MUPF adhesives are used. The individual plates can identify several adhesives. Thus, it is possible to use a different adhesive in the middle layer than in the cover layer.

Prices for chipboard

The manufacturers usually quote the prices for the chipboard in the form of a price list. A price list offers a comprehensive overview of the different thicknesses, sizes and designs. Decide on the price:

- the dimensions

- whether the plates have tongue and groove

- whether the plates are ground

- the strenght

- the quality

If the plate has tongue and groove, then it is quickly and easily laid on the floor and provides a stable hold. It must also be noted how many sides the straight edge is and whether it is ground or unpolished plates. If the coarse chipboard has too large a form or if it has to be adapted to corners and curves, then it is relatively easy to cut. This gives you flexibility and the right dimensions for the panels for every application.

The details of the prices

When specifying the prices, there are two different options: On the one hand, the price per plate can be specified in a price list. This gives you a direct overview of the total when you know the number of plates you need. Make a plan of the area to be covered and determine how many plates you need. You can either work with coarse chipboards of equal lengths and widths or with different sizes, as long as the thickness matches.

The second possibility of quoting refers to the area. In the price list you will not find the individual prices in this case, but the information refers to the purchased square meters. If you know the dimensions of the total area that you want to disguise, then you can get a quick overview of the total costs. If it is a rectangular area, then multiply the length and width and get the area. Only rough information can be given for the prices, since above all the quality and the thickness are crucial. For example, panels with a thickness of 15 millimeters cost between 4 and 11 euros per square meter.

Examples of different sizes, strengths and prices

1. Plate size: 184 cm x 67.5 cm; unpolished; with tongue and groove

- Strengths: 12 mm, price per square meter: 3, 69 Euro

- Strengths: 15 mm, price per square meter: 5.29 euros

- Strengths: 22 mm, price per square meter: 7, 39 euros

2. Plate size: 184 cm x 67.5 cm; ground; with tongue and groove

- Strengths: 12 mm, price per square meter: 5.98 euros

3. Plate size: 62.5 cm x 205 cm; unpolished

- Thickness: 12 mm, price per square meter: 3, 22 Euro

4. Plate size: 67.5 cm x 205 cm; unpolished

- Thickness: 12 mm, price per square meter: 3, 22 Euro

5. Plate size: 67.5 cm x 125 cm

- Strengths: 15 mm, price per square meter: 7, 31 Euro

Source: www.Obi.de at point 1 and 2) Hornbach at point 3 to 5)

Tip: If you find a cheap offer on a coarse chipboard with tongue and groove, but need a straight edge, then you can customize margins by hand and thus get the desired execution.

Calculate weight

To calculate the weight of an OSB board, the specific gravity of 616 kg / m³ is taken. From this, the weights of the individual plates can be derived:

Plate: 2050 mm x 675 mm x 22 mm = 0.03044 m³ = 18.5 kg

Tips for quick readers:

- pay attention to the category according to EN 300

- select the same thickness

- The size and thickness of the OSB board determine the weight

- Tongue and groove is easy to lay

- OSB boards can be cut to size