Smooth concrete - that's how you get smooth concrete surfaces

- Maturing process of concrete

- Smooth and compact fresh concrete

- Compact concrete

- Smooth concrete

- Smooth out the ripening concrete

- Smoothing hard concrete: blasting, sanding and polishing

- radiate

- grind

- polishing

- Seal concrete

Smooth concrete - Concrete is a liquid mixture of cement, water, sand and gravel when it is delivered. In order for it to be used meaningfully, it must be poured into stable molds. Concrete has primarily technical tasks. Visually, he is not very appealing due to its gray color. Nevertheless, it makes sense to let it solidify with as smooth a surface as possible.

On the sides of a concrete body, a smooth surface provides a good basis for further processing. A smooth top, for example in a concrete pavement, makes the further construction of the floor coverings considerably easier. Concrete is a very flexible material that can be processed with the appropriate device in any state of hardness.

Maturing process of concrete

Fresh concrete hardens in three stages:

- Liquid

- maturing

- curing

Concrete is poured into the formwork in the liquid or plastic state. He is completely soft and follows only the laws of gravity. Concrete can not be kneaded or piled up, but flows and sinks along the path of least resistance. This condition he retains for about 1 hour after mixing.

If the concrete "ripens", then it no longer flows, but still has a moist and soluble surface. The cement slurry can still be washed out. For example, ready-mixed concrete is produced.

After about 24 hours, the concrete is completely cured or set. Its surface can now only be edited with heavy equipment and a lot of power. However, the industry also offers the right tool for this state of hardness.

Smooth and compact fresh concrete

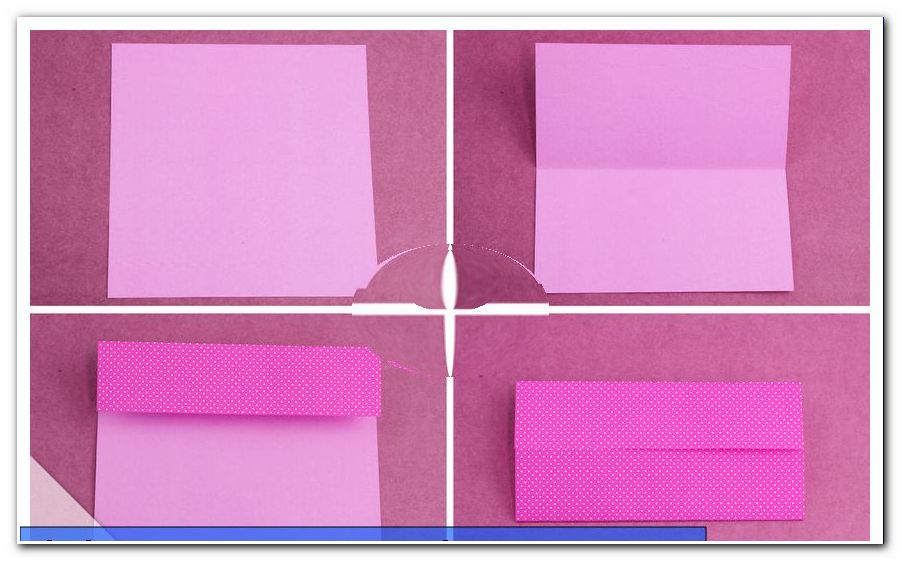

The easiest way to smooth concrete is to shed it. Here it must be distinguished whether the concrete body should receive only as smooth as possible surface on its top or on the other side. In the case of wall elements, a smooth surface on the side, on joists and concrete ceilings on the underside of the concrete also makes sense. For this purpose, the inside of the formwork is lined with plates, which have the smoothest possible surface.

The proven standard material for decades for this purpose is "Betoplan". These are easily machined multiplex panels with a particularly smooth surface. These panels are simply cut with a circular saw and also attached with as few nails on the inside of a formwork. When calculating the formwork, the wall thickness of the betoplane must be taken into account. Betoplan has a thickness of 21 to 27 mm and costs about 28 euros per square meter . If a structured surface is desired instead of a smooth one, very interesting effects can be achieved with the appropriate formwork.

Before filling the concrete into the formwork, it must be generously sprayed with formwork oil. Dry areas may tear when removing the formwork. In order to get the concrete body smooth again at this point, reworking by trowelling and smoothing is necessary. This can be saved if the formwork is oiled.

Where concrete and external formwork meet, the emerging cement slurry automatically creates a smooth surface. The biggest enemy of the smooth structure is trapped air. This is removed during concreting by consistent compacting. For this purpose, vibrators or vibrating bottles are used.

Vibrating bottles, also called "compressors", are construction equipment that is particularly important for the introduction of concrete in wall formwork. They ensure that the concrete is actually completely distributed within the formwork and also runs into the furthest corners. When concreting concrete floors, the vibrator provides a leveling of the surface, which simplifies the subsequent smoothing.

Compact concrete

Concrete vibrators are highly effective devices that can greatly simplify concreting work and significantly improve results. To use the vibrator properly, a few basic skills are important.

The vibrator consists of a long and heavy hose, which is connected on one side to an electric motor and on the other side has a bottle-shaped tip. In this tip, an unbalance rotates, creating the strong vibrations of the vibrator.

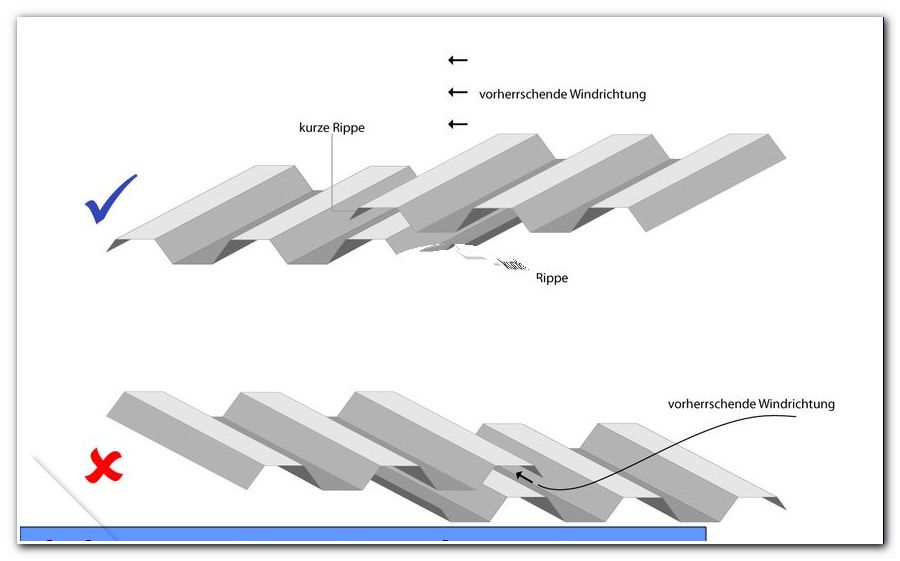

For wall formwork, it makes sense to let the vibrator down to the bottom of the formwork before pouring the concrete. Once the formwork has been filled, the vibrator no longer reaches the ground. It is ideal if it can be concreted in layers. Before each filling step, the concrete is thoroughly "shaken" until no more air bubbles rise. But beware: If too much and too long shaking, the concrete segregates and loses its strength.

For heavily reinforced formwork, consistent compacting is particularly important. Only completely enclosed with concrete structural steel is protected against corrosion and can thus ensure long-term stability. When shaking off reinforced concrete, make sure that the vibrating bottle does not stick or get stuck. This happens relatively easily. In the worst case, the bottle must be cut off and left in the formwork.

For slab formwork, the vibrator is immersed in the fresh concrete every 30-50 cm. The concrete levels out immediately and creates an already even surface. A well-shaken and leveled concrete pavement is much easier to smooth and coat.

After concreting, the vibrator must be thoroughly cleaned. Caking concrete is difficult to remove. Therefore, it makes sense to spray the vibrator thoroughly with scarf oil before use. A jogger costs about 36 euros in the daily rent.

Smooth concrete

After shaking a concrete ceiling or a floor slab follows the smoothing. There are several methods available for this. It is sufficient to nail a piece of betoplan to a broomstick to make a functional concrete smoother. Better results, however, promise more professional handheld devices. These are sold under the name "Betonglätter", "Betonabzieher" or "Betonverteiler" and cost between 40 and 180 euros. They consist of a steel sheet to which a receptacle for a stem is welded. These hand tools are pulled directly over the freshly compacted concrete. They only serve to push suspended gravel back into the fresh concrete mass. With light shaking the concrete can be leveled out a bit. Too much pressure, however, can make the newly freshly straightened concrete hilly again.

The next evolutionary stage of hand-operated concrete trowels are pullers with motor. Here sits on the puller a small gasoline engine, which puts the transverse blade in slight vibration. This achieves a particularly smooth surface.

These devices are a real recommendation as they make the job much easier. Unfortunately, they are rarely to be found at the rental stations. The daily rent for a gasoline powered concrete trowel is about 65 Euro.

Smooth out the ripening concrete

The most common machine for smoothing concrete is the trowel . It consists of a powered wing propeller that drags over the freshly matured concrete. In order to use the trowel, the concrete must have already set so far that you can enter it without sinking.

For small concrete surfaces, a hand-operated trowel is sufficient. It is driven by an electric or petrol engine and simply swung back and forth over the concrete surface. The wings, which constantly stroke the fresh concrete, not only smooth the surface. They also stimulate the capillary action of the fresh concrete. As a result, the cement slurry flours on and also ensures an absolutely flat surface.

Ride-on trowels are available for large concrete surfaces. They are very efficient. Their operation also requires some practice. Ride-on trowels are equipped with two propellers. Hand-operated trowels cost between 65 and 120 euros per day. Ride-on trowels, also called twin trowels, cost about 250 euros per day. However, they usually also cost a high deposit, which is only partially refunded if the unit has not been cleaned. A thorough spraying with form oil and just as careful cleaning can help save costs.

The winged propeller creates a concrete surface of defined flatness. It can be used again as a starting point for structuring that has just been defined.

In some applications, a roughened concrete floor is useful, for example, when a liquid screed is to be applied. A roughened floor reinforces the connection between the individual layers. For roughening and structuring the freshly smoothed concrete, it is sufficient to carefully pull it over a plastic broom.

Smoothing hard concrete: blasting, sanding and polishing

Modern construction technology also offers suitable smoothing equipment for renovation projects, with which concrete surfaces can be straightened. What was a very dirty and exhausting task just a few years ago can now be done quickly and cleanly with modern machinery.

radiate

The breakthrough in the smoothening technique of old concrete was the shot peening machine. This shoots high pressure small steel balls on the concrete floor and sucks it off immediately. These machines therefore operate extremely low in dust and are very easy to operate. With working widths of 30-50 cm, even large concrete surfaces can be leveled out quickly. A shot blast machine costs between 100 and 250 euros per day. As a buying device, however, they are far too expensive for home improvement. For a new shot peening machine, the purchase price must be between 6, 000 and 22, 000 euros.

grind

Although the shot peening machine levels the largest irregularities in an old concrete surface, it only produces a very rough surface. To smooth this roughened concrete, concrete grinding machines are used. These are structurally very similar with the wing trowels or with leveling machines: on a long handle, a motor with sanding disc is attached, which drives the sanding pad. The abrasive used are elements with diamond coating or tungsten carbide. These are very durable and slow down. Modern concrete grinding machines have an integrated extraction system, so that working with these devices is very clean. A concrete grinder is also great for removing old remnants of glue or putty.

Hand grinding machines for the kneeling corner work cost approx. 30 euro daily rent. Disc grinders for standing or walking are available from about 90 euros rent per day.

polishing

In some cases, sanding a surface to smooth the concrete is not enough. Then in the final step, the concrete surface can be polished. Also industry and trade offer suitable devices. First of all, any commercially available concrete grinding machine can also be converted into a polishing machine by means of the appropriate abrasives. However, the machines designed especially for a concrete polish promise a particularly fine and fast finish. These are available in many variants on the market. Second-hand machines, which are technically closely related to the ride-on concrete trowels for fresh concrete, are particularly efficient. These machines work very fast and produce a particularly smooth surface due to their wet grinding.

Seal concrete

Freshly smoothed and polished concrete surfaces are very sensitive. The capillaries in the concrete are open after the removal of the top cement layer and thus very absorbent. Each spilled liquid penetrates deep into the concrete and creates unsightly stains. Therefore, sealing the surface immediately after sanding and polishing the concrete is very important. Epoxy resin-based concrete sealing therefore offers a durable and scratch-resistant solution. These agents, also sold as "liquid plastic" can be applied with a roll or simply poured out. They level themselves out and therefore produce an absolutely smooth surface. Concrete sealing is commercially available as a clear or as a colored agent. The liter price is about 48 euros . However, the construction height is only about 0.5 millimeters, so that even small containers are very economical. With clear concrete seals, the sanded and polished concrete darkens and creates a very appealing, high-contrast pattern.

Tips for quick readers

- Always shake fresh concrete thoroughly

- When concreting columns or walls, insert the vibrator bottle beforehand

- not too long shaking

- Machine trowels are very effective on floor slabs and ceilings

- no longer step on smoothed concrete

- Cover the fresh concrete with foil at hot temperatures

- Grinding and polishing concrete produces interesting optical effects

- Always seal ground and polished concrete