Trapezoidal sheet - dimensions, prices and assembly instructions for laying

- Simple production

- Prices for trapezoidal sheets

- Prices for sandwich panels

- Laying trapezoidal sheet metal

- Assembly instructions for trapezoidal sheets

- Tips for quick readers

Low-cost construction with trapezoidal sheet - trapezoidal sheets are building materials for the roof skin and for the wall construction. They are especially popular in industrial construction. Trapezoidal sheet has a high intrinsic stability and can be laid very quickly. Due to its simple production method, it is very inexpensive. The extension of the trapezoidal sheet are the sandwich panels. With these innovative building materials, two trapezoidal sheets with a core of insulating material form a unit that meets even the most modern requirements in terms of thermal insulation. Find out everything you need to know about trapezoidal sheets and sandwich panels in this text.

Ideal inherent stability

Trapezoidal sheets are folded long sheets. The folded contour is trapezoidal, so this building material has its name. The profiling makes the sheet very stiff. It does not bend in the longitudinal direction. In the transverse direction provides a support structure on which the sheets are welded, for the necessary stability. Once installed, many holes can be made from the trapezoidal sheets and holes can be cut. As long as a one-sided or complete cutting is prevented, the sheet retains its stability.

Inexpensive starting materials

The basic material of trapezoidal sheets are flat materials made of steel or aluminum. Steel is much cheaper, but must be sealed for corrosion protection. For this purpose, the steel sheets are usually galvanized and then coated again with polyester. However, this coating already happens in the rolling mill. Since the coils are always processed to large quantities of trapezoidal sheets, the cost of the coating is usually manageable. 1A materials are usually issued with a five-year rust prevention warranty.

Aluminum sheets do not necessarily need corrosion protection. In addition, they are lighter than steel sheets. However, they are more expensive to manufacture, which makes them less popular.

Copper trapezoidal sheets are occasionally available, but these are extremely expensive.

Typical thicknesses for trapezoidal sheets are:

- Steel, coated: 0, 4 - 0, 8 mm

- Aluminum, uncoated: 0.4 - 1.00 millimeters

Simple production

The production of trapezoidal sheets is very simple: The coil is hung in a reel and unwound. The tape is passed over a profile rolling road. It is guided between the top and bottom press rolls. With a bend and edging over several steps, the desired profile is produced. At the end of the roller mill, the sheet is cut off. The sheets are always designed so that they can be easily stacked. Again, the trapezoidal cross-section of the sheet metal profile is advantageous.

With sandwich panels, the process is simply doubled: an upper sheet is supplemented by a lower sheet. Polystyrene is injected between the two sheets. The sandwich panel then passes through a special oven where the polystyrene cures. Subsequently, the finished sandwich panel is cut with a cutter. The sandwich panels are also easy to stack.

Prices for trapezoidal sheets

Trapezoidal sheet and sandwich panel are manufactured as a roof or facade element. Their particular advantage is that they are largely self-supporting. Where neither the aesthetically nor constructively particularly great challenges are posed to the new building, trapezoidal sheet metal and sandwich panels can be used to quickly convert large volumes.

There is no single standard for the production of trapezoidal sheets. However, they must be approved in accordance with DIN EN 1090 "Certification of load-bearing components". Each manufacturer offers its own variants here. These are not always compatible with those of other producers. However, three basic types can be derived, to which all manufacturers more or less stick. These are

- Flat trapezoidal sheets

- Central profiled sheeting

- High profiled sheeting

The main difference between these three types is the height at which the characteristic trapezoidal sheet is formed.

Flat trapezoidal sheets are mainly used for roofs. The widths of the raw sheets are always the same. The higher a trapezoidal profile is formed, the narrower the finished trapezoidal sheets. Therefore, the sheets for the roof skin are usually equipped only with a low trapezoid. They cover a larger roof area with sufficient inherent stability. They also offer less resistance to attacking wind. However, the highly profiled trapezoidal sheets are usually also designed as a roof element. They are well suited for particularly wide spans due to their strong profiling. In addition to the high inherent stability, which makes it ideal for flat roofs or flat roof pitches, among other things, the deep gutters also offer ideal drainage options for rainwater.

The dealer M + M offers its trapezoidal sheets in the W20 and W35 flat profile. The W20 profile states that the rolled-in harness has a height of 20 mm. The prices of M + M are:

| Corrugated boards | price |

| W20 steel sheet thickness 0.5 mm polyester coating 25 μm basis weight 4.8 kg / m² | 9, 40 Euro / m² |

| W20 steel sheet thickness 0.5 mm polyester coating 35 μm basis weight 4.8 kg / m² | 10, 40 Euro / m² |

| W20 steel sheet thickness 0.5 mm TTHD coating 60 μm Basis weight 4.8 kg / m² | 11, 40 Euro / m² |

| W20 steel sheet thickness 0.63 millimeters polyester coating 25 microns basis weight 6.05 kg / m² | 10, 80 Euro / m² |

| W20 steel sheet thickness 0.75 mm polyester coating 25 μm basis weight 7.02 kg / m² | 11, 40 Euro / m² |

| W20 aluminum sheet thickness 0.7 mm polyester coating 25 μm basis weight 2.0 kg / m² | 13 Euro / m² |

| W35 steel sheet thickness 0.5 mm polyester coating 25 μm basis weight 5.01 kg / m² | 9, 80 Euro / m² |

| W35 galvanized steel sheet thickness 0.5 mm polyester coating 25 μm basis weight 5.01 kg / m² | 11 euros / m² |

| W35 sheet steel thickness 0.5 mm TTHD coating 60 μm Basis weight 5.01 kg / m² | 12, 50 Euro / m² |

| W35 steel sheet thickness 0.63 millimeters polyester coating 25 microns basis weight 6.45 kg / m² | 11 euros / m² |

| W35 steel sheet thickness 0.75 mm polyester coating 25 μm basis weight 7.60 kg / m² | 12, 50 Euro / m² |

| W35 aluminum thickness 0.75 millimeters polyester coating 25 microns basis weight 2.30 kg / m² | 13, 50 Euro / m² |

Tip: All manufacturers offer a selection of trapezoidal sheet metal from the second choice. Here can be saved significantly! Square meter prices from 5 euros per square meter are quite possible!

A trapezoidal sheet with high profile has a thickness of 50 - 200 millimeters. The higher the trapezoid is formed, the stiffer the trapezoidal sheet and the greater its technically possible span. Therefore, the high profiles are delivered in sheet lengths of up to 27 meters. The prices are based on the flat profiles. The base material remains the same and the processing of high profiles is not expensive than with flat or medium profiles.

Prices for sandwich panels

The upgrades of the trapezoidal sheets, the sandwich panels, of course, have significantly higher prices than the simple profiled sheets. They are tremendously practical for that: they can not only be beneficial for heat protection. Installed as a roof element, the sandwich panels already provide for a considerable damping of noise during rainfall. The low prices of the trapezoidal sheets quickly become a curse, if one sees oneself exposed to the constant drumming of a rain or hailstorm. That is why, especially in the case of residential buildings or working spaces under the roof, a sandwich element should be chosen as far as possible.

Amazingly, the prices for sandwich panels are not so much higher than you might expect: prices start from 14 euros per square meter and reach up to about 25 euros per square meter. When laying, however, they are more demanding: It is in any case a crane needed. Due to their heavy weight, manual laying or correction is not possible.

Laying trapezoidal sheet metal

For the installation of trapezoidal sheet metal it is absolutely necessary to have an installation manual. Basically, the sheet is bolted to a substructure for laying. However, the type of screw connection must be carried out correctly according to the installation instructions. Every puncture from the sheet creates a point where rust can attack. This not only ensures ugly stains and gradients within a very short time after installation. The thin sheet can be completely rusted without installation according to installation instructions and quickly. In the worst case, negligence and installation errors can affect the entire static of the building. Then even low prices when buying sheet metal and mounting materials do not help anymore.

When laying roof surfaces you should always pay attention to the insulation. Only where it is really not necessary, such as in garages or warehouses, can be dispensed with an insulation. The insulation not only shields against the rising sun. Above all, it provides the necessary sound insulation. With all the advantages offered by a trapezoidal sheet, the soundproofing of these components is completely inadequate.

Tip: Today the industry has developed roof tile trapezoidal sheets for home builders. This extremely smart solution simulates a decent tile roof in almost perfect way. The prices are only marginally higher than the normal trapezoidal profiles. When laying the roof tile profile sheets make little difference to the normal roof sheets.

Assembly instructions for trapezoidal sheets

1. Handling

- Trapezoidal sheets should always be carried individually and with two persons

- Trapezoidal sheets up to 6 meters in length can be unloaded and transported by fork-lift truck. Always pay attention to the center of gravity

- From a length of 6 meters, a crane is required for unloading and transport. Be sure to use a side guard and additional supports as the attached panels can easily deform.

- From a length of 10 meters an additional traverse is required for unloading and transport. Use enough sling straps to keep the pack from sagging!

2. Processing and cleaning

Ideal for processing sheets are "nibblers". These are electric metal scissors. They cost in good quality from about 240 euros. They can also be rented for 30 euros per weekend. Angle grinders or saws produce many chips. These must be completely removed, otherwise they may rust immediately after installation.

Clean contaminated sheets before laying.

3. Lay according to installation instructions

Roof and facade panels are always laid overlapping. At least two sealing strips must be installed at each overlap. The overlap must be at least 200 millimeters. Overlapping is always done by nesting the profiles. If the 200 millimeters far exceeded the profile, this is acceptable.

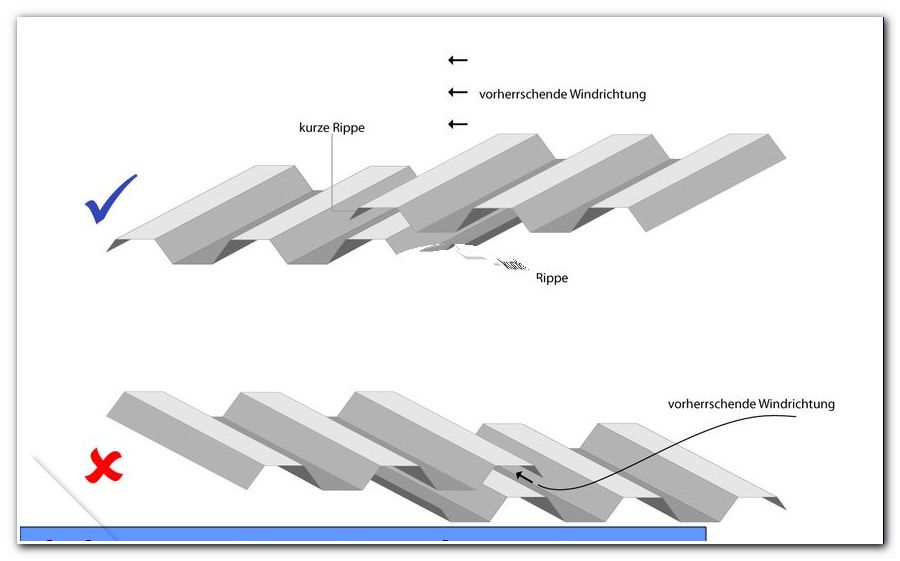

The overlap must always be such that running rainwater does not hit an edge. It has to flow gently from sheet to sheet.

The transverse overlap is always aligned with the prevailing wind direction. This applies to both the facade panels and the roof panels.

The manufacturers prescribe how many screw connections per square meter are required for the respective trapezoidal sheet metal. This requirement must always be followed when laying, even if the assembly instructions suggest a different quantity.

Always close holes correctly. To do this, use the gaskets supplied. An additional applied rust sealant (eg Hammerite) ensures improved corrosion protection.

Always install connecting plates, gutters and wind catches in accordance with the installation instructions. Mistakes during installation are quickly noticeable due to penetrating water and wind noise.

Tips for quick readers

- Compare prices and pay attention to special offers

- If possible also consider offers for second choice

- Always install the correct amount of screws

- Watch out for rust! Seal each hole as good as possible!

- Insulate roofs whenever possible. Ideally lay sandwich panels from the outset

- No mistakes when unloading or transporting long profiles! Use cranes and trusses.