Fiber cement boards - characteristics, types and prices

- Advantages and disadvantages of Eternit plates

- Products and prices

- corrugated sheets

- roof shingles

- Small slabs for roof and facade

- Roof and facade stones

- facade panels

- Ortplatten

- Panels for interior work

- Wall formwork for the outside

- plates of balconies

- Tips for quick readers

Fiber cement boards are thin sheets of cement and a carrier mesh. They are thus among the "composite materials". The panels are very precise to produce and are thus suitable for all kinds of visible surfaces. Today, they are mainly used in facade construction and roofing. The basic materials of the fiberboard are very inexpensive, so that the finished panels are also low in price. The panels are an extremely cost-effective alternative to other types of cladding such as natural slates, aluminum panels or Dibond products. Prices are similar to clinker prices, but they are much easier and faster to process.

Today free of asbestos

Hardly any building material has undergone such dramatic changes in perception as asbestos. These once celebrated as "miracle fibers" minerals are largely prohibited today. The hopes of these ceramic fibers were great: Extremely resistant, especially to heat, asbestos fibers were the ultimate - and not only in the construction industry. Asbestos has also become famous for the suits named after it, with which a completely new occupational safety could be achieved at blast furnaces and smelting works. However, today it is well known that asbestos are extremely dangerous to the lungs and are suspected of being highly carcinogenic.

If you are still dealing with asbestos boards and want to dispose of them cleanly and safely, we have put together all the information here: dispose of asbestos

In the fiber cement boards, the asbestos fibers were replaced by other materials. Today, mainly glass fibers are used here. These are not only extremely inexpensive, but also very tear-resistant. The durability of the plates has not changed to this day, which is why they still bear the name "Eternit".

Almost for eternity

The inventor of a new product can boast of the honor of becoming its eponym. So it was with Styrofoam and the rigid foams, Uhu and the adhesive, Tesafilm for the tape and ultimately also the Eternit for the fiber cement boards. Today there are a lot of manufacturers of fiber cement boards. But the "Eternit" is today synonymous with this product type in general-language use. Eternit comes from the word "Eternity", which means "eternity". This was the aim of the Austrian inventor Ludwig Hatschek, who had this product developed by him from 1903 protected by this name. The then rapidly spreading fires that could easily jump from one house to the next, were effectively contained with this inexpensive and easy to process material. This contributed significantly to the success of this product.

If you need to dispose of Eternit plates, you will find out exactly how best to use them and what to pay attention to: Dispose of Eternit

Advantages and disadvantages of Eternit plates

Ultimately, these products are just simple composites of cement and ceramic fiber. They are simple and inexpensive to manufacture and can be pre-assembled in any shapes. With the addition of dyes in the cement mixture, a variety of color accentuated panels can be produced. Summed up are the advantages of fiber cement boards:

- inexpensive

- Precise

- Great color and shape selection

- Easy to work with

- Very durable

- Easy to coat or clean

- Easy to dispose of

The disadvantages of these building materials are mostly history. The health hazard is banned with the change to fiberglass and other non-hazardous carrier materials. What was a criticism of cement slabs for a long time was the aesthetics. Here, all manufacturers, and of course the namesake itself very special, have done tremendous. The once extremely monotonous and less aesthetic plates always had a rather "modern" touch. For several decades, however, this has led to rows of beautiful half-timbered houses disappearing behind boring cement-board facades. This is no longer done in the form today, especially since the preservation of monuments hardly granted the necessary permits here. However, the fiber cement products available today are aesthetically mature and by no means have the cheap appeal of the first generations of these materials.

Products and prices

Cement is liquid during mixing and mineral fibers are flexible. The products are simply poured into the desired shapes and allowed to cure. The shape design of the products is correspondingly large and hardly exposed to physical limitations. Nevertheless, a certain type of building board has become established in fiber cement products. This is constantly varied and adapted to the fashions. However, the ideal fields of application for Eternit have been found. For example, pipes are barely made of this material today. The usual fiber cement products are today:

- facade panels

- roof shingles

- corrugated sheets

- Interior panels

- plates of balconies

The largest selection is the ETERNIT brand itself. Other manufacturers include CEMFORT or CREATON. However, these manufacturers are essentially limited to roofing.

The product selection of fiber cement panels is now quite large. They are offered in many different colors, shapes and textures. Here is the simple production of fiber cement panels from their particularly grateful side: To bring an interesting texture in the final product, it is sufficient to line the mold accordingly. So a currently very popular texture is the natural, organic wood grain.

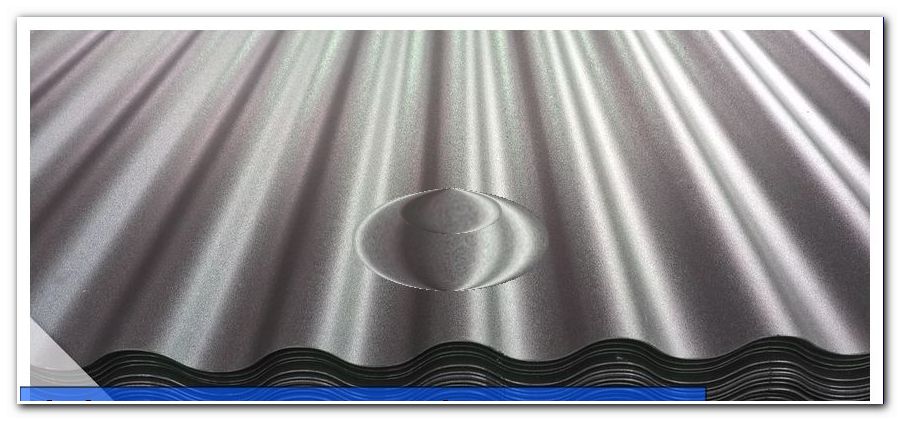

corrugated sheets

The shingles known as the "Berliner Welle" are visually indistinguishable from the fired bricks. They are, however, much more resistant to breakage. It is sold as "Type OA" and is a short corrugated plate in which the corner cut is missing. It is ideal for large roofs, as it provides it with small-scale structures. Their biggest advantage over roof tiles is that they can be made very large. Pure clay shingles become the more fragile the wider and thinner they become. Due to the reinforcing inner fiber, the corrugated sheets can be produced in a length of 0.83 meters. For a square meter of roof area only about 2.3 shingles are needed. Ultimately, this is also very economical when laying. These fiber cement boards are not dyed in the manufacturing process, but only coated afterwards. For this purpose, an acrylic is used, which is particularly resistant to weathering, acids and UV light.

The colors offered are dark brown, dark red and dark gray for the corrugated sheets. The fiber reinforcement also allows the production of "long profiles". With these up to 2.5 meters long and 1.0 meters wide plates, the roofing goes very fast

The prices for the corrugated sheets are as follows:

- Berlin wave 325 millimeters long: prices from 12 euros per piece

- Corrugated sheets Long profile 1250 to 2500 mm length and 920 mm width: Prices from 31 Euro / piece

- Corrugated sheets Long profile 1250 to 2500 mm length and 1000 mm width: Prices from 37 Euro / piece

roof shingles

The classic roof shingles are also available as fiber cement boards. The wavy or flat roof tiles are much cheaper, but also much smaller than the corrugated sheets. They are decorated with sonorous names like "Heidelberg", "Gothenburg" or "Verona". For one square meter you need up to ten stones. The prices start at approx. 0.50 Euro per piece.

The much larger "jumbos" offer a much larger roof coverage per stone. They are 450 millimeters wide and are available in every shingle design. The prices for the jumbo stones start at about 6.50 per piece.

Small slabs for roof and facade

Smooth small plates made of Eternit are suitable for both roofing and façade construction. They are very simply designed and are particularly suitable for ventilated facades with a thermal insulation composite system. The plates are 0.2 x 0.2 meters in size. For a square meter about 40 plates are needed. The prices start at 0.75 euros per piece or at about 15 euros per packaging unit. These VpE always consist of 20 pieces. That makes a price per square meter of about 30 euros.

Roof and facade stones

The roof and façade stones are indeed attached with a scaffold. But they allow in contrast to the small plates an arrangement in the staggered association. This creates a "bricked impression" of the facade. They are 30 x 30 cm² in size. Prices start at 1.75 euros each.

facade panels

The transition from universal panels to pure facade panels is fluid. The smallest form of pure facade panels made of Eternit has dimensions of 30 x 60 cm². At the same time there are also roof and façade bricks with the same dimensions. The demand per square meter is, depending on the roof pitch, about 11 to 13 pieces. The prices are with the facade plates and the large universal stones at approx. 4 euro per piece.

Ortplatten

Ortplatten are smooth boards with an edge length of 60 x 30 cm². They are particularly easy to process and can be cut well with suitable tools.

Panels for interior work

With the extremely noble and fascinatingly textured panels for interior finishing Eternit has finally put off the boring stigma of the old flat panels for roof and facade. What the manufacturer can offer in this area as an alternative to the classic tile is extremely commendable. However, the large panels for the cladding of ceilings and walls, referred to as "indoor panels", have their prices: They start at around 166 euros per square meter. For this, however, you get a durable, robust and extremely aesthetic large plate that has lost none of its effect for decades.

Wall formwork for the outside

Outdoor wall formwork is a fast, practical and highly aesthetic way to dress the house. The manufacturers offer different systems here. They consist of long panels that can be installed either horizontally or vertically. With a length of 3.60 meters and a width of 0.19 meters they are extremely efficient to process. Prices start at around 20 euros each. The user already has a large selection of textures, textures and colors to choose from.

plates of balconies

The fiber cement panels for the balcony cladding are identical in texture and thickness to the wall formworks. They are only offered in much larger formats. The standard dimensions for these panels are 3.10 mx 1.25 m and 2.50 mx 1.25 m. They are offered in thicknesses of 8 or 12 mm. Prices start at 62 euros per square meter and range up to 115 euros per square meter. With a plate of over four square meters, this makes unit prices of over 500 euros - per plate. Thus, the balcony slabs are certainly one of the most aesthetic and durable ways to disguise his balcony. Certainly not one of the cheapest.

Tips for quick readers

- Plan fiber cement boards well. They require many measures in the substructure

- Have old fiber cement panels inspected before removal. They could contain asbestos.

- Dispose of asbestos boards always professionally. Otherwise there are threats to health and high fines.

- Always compare prices. Often cheap residual and special items can be determined.

- Second or third choice is sufficient for the higher facade panels. This can also save a lot of money

- Observe the safety during processing. Even large panels always with the maximum in safety and always obstruct the rule and the appropriate tool

- When installing a composite thermal insulation system, use only fibrous materials such as glass wool or rock wool. Polystyrene is extremely problematic today and should no longer be used.

- Fiber cement panels provide optimal weather protection and a significant upgrade of the whole house. They are perfect for remedial measures.

- Corrugated sheets are suitable for efficient roofing, especially in the large versions. Again, always pay attention to safety.

- The name "Eternit" guarantees the best manufacturer quality