Stick silicone - use as adhesive / glue silicone surfaces

- Why stick with silicone "> Use silicone glue

- material

- preparation

- manual

- Glue silicone surfaces

- Related Links

For many decades, silicone has been one of the most important elastic sealants in building construction. It can be used in a wide range of applications, but silicone is most commonly used to seal joints in the kitchen or bathroom. However, many materials can be linked to the fabric because of its properties, even though the bonding of silicone surfaces proves to be difficult. In this tutorial you will learn how to glue silicone or which adhesive is suitable for silicone surfaces.

Synthetic polymers, which include silicones, prove by their properties to be an effective means of compacting joints and use in many industrial applications. They are temperature resistant, can be applied in liquid form and then harden without leaving. In house building they are often used in wet rooms, kitchens and for windows, rarely for bars, but the material can also be used as an excellent adhesive. Especially for objects or surfaces that are not exposed to strong shocks or vibrations, silicone adhesive can be used. This makes it all the more difficult to glue silicone surfaces, as they are only weakly adhesive.

Why stick with silicone?

Due to its special properties, silicone is suitable as a material for a multitude of uses that require elastic compression and adhesive agents. These are:

- resistant to aging

- hardly suffers wear

- Withstands temperatures from -50 ° C to over 300 ° C

- is not affected by temperature fluctuations in the form and effect

- effectively acts as an electrical insulator

- environmentally friendly

- insensitive to aggressive cleaning agents and diluted acids

These are the benefits you can take advantage of when sticking with silicone. Even outdoors, you can use silicone glue to bond, for example, two surfaces in your garden shed that can not be fixed with conventional adhesives or other fasteners. Above all, the following materials can be glued well with silicone adhesive:

- ceramics

- Wood

- plastic

- Glass

- enamel

- Metals, especially aluminum and stainless steel

Even cardboard and paper can be stuck with the fabric, but the use is not really worthwhile. Above all, joints, holes and even damage can be filled with all these materials. A major drawback to the fabric is the poor performance in motion, recurring vibrations and severe tearing on the bonded article. Since silicones achieve a high adhesive effect and then become hard, too strong movements can inevitably damage the adhesive, whereupon it must be renewed. Typical applications (small selection) can be:

- PC components, especially CPUs

- Automotive parts

- Repairs in the apartment, for example, oven seal

- Fixing bulbs on different surfaces

Tip: If you want to glue wood to silicone, you must make sure that heavily oiled wood often adheres worse or even loosens again. Silicones do not work well with oiled surfaces and therefore the result can be very different.

Use silicone glue

material

Once you have decided to use the silicone adhesive, you will need to make some preparations for the application. Important are of course the necessary materials and utensils:

- Silicone or silicone glue

- silicone gun

- cutter

- Spatula or spatula

- rubber gloves

It is not recommended to use the classic silicones used to compact joints. Their adhesive power is much lower than the special silicone adhesives, which were designed for gluing work and therefore can glue together many materials. Typical manufacturers of these adhesives are BEST and ADCHEM, whose adhesives are based in part on silicon compounds and thus permanently increase the adhesive performance. Since it is specifically about the bonding with silicones, special silicone pullers are not needed, which are otherwise used for joints and seals.

Tip: Some manufacturers offer small tubes that are even applied without a silicone gun. These have special attachments and are mainly offered for small applications that do not require large amounts of silicone adhesive.

preparation

Before you can tackle the project, you must first prepare the materials you want to bond. Likewise, preparation includes setting up the silicone gun. Here's how to do it:

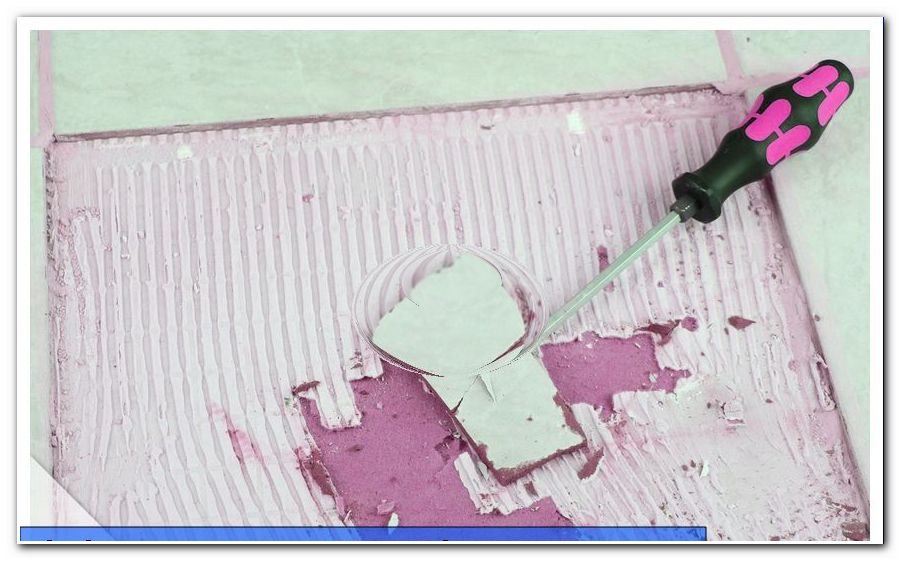

- clean the materials or components to be glued

- depending on the component, different procedures have to be used

- with PC components, for example, dust is mostly removed

- glass plates to be glued on the other hand should be cleaned with cleaning agents and freed of grease residues

- It is important to clean the surfaces to be glued

- the rest of the surfaces do not need to be cleaned

- Dry the materials or materials thoroughly after cleaning

- Moisture acts against the adhesive effect of the adhesive

- If you are using an already used silicone gun, you must clean it beforehand, if any residues are present

- usually residues can be easily removed and disposed of

- if some residue is a little tighter, simply scrape it off

- uneven areas need to be repaired

- that is, wood should be sanded, metal bulged and other materials processed accordingly

manual

After you get the materials and utensils, you can finally start gluing after the preparation. Always make sure to wear rubber gloves while you are gluing because you do not want the glue on your skin due to the strong adhesive power. Although the adhesive does not really cause any injuries, it is not ideal if your fingers stick together at one go or if foreign matter such as the plastic cap of the cartridge does not escape. This not only restricts the work but also often requires the use of a solvent. The instructions as follows:

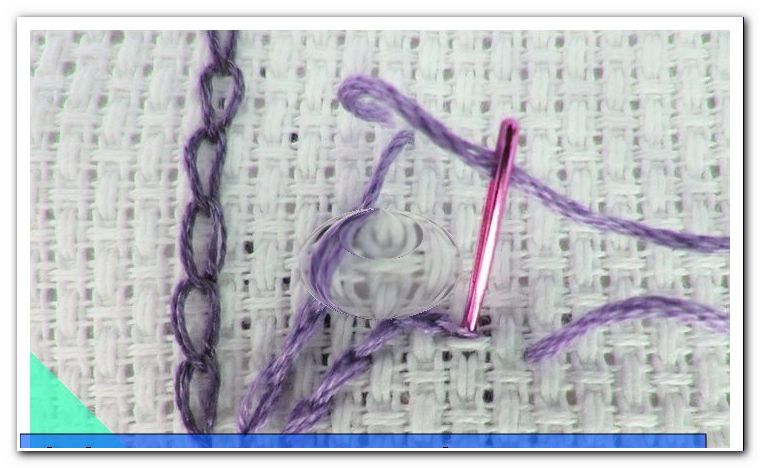

Step 1: Prepare the cartridge. If you do not use small tubes, open the cartridge with the silicone with a cutter or scissors. Then the cartridge is inserted into the gun, fixed and can now be used. Wear gloves here!

Step 2: After the cartridge has been installed, select the surface to be bonded. Make sure you connect the surfaces that are least moving at the end. This counteracts possible cracking of the silicone.

Step 3: Apply thin strips of silicone to the surface in succession. The larger the area, the higher the dosage must be. Do not place the webs too close to each other as silicone softens slightly on contact pressure. As a result, the distances are filled by itself. The tracks themselves should not and should not be too thick. Use a little sparingly, because the adhesive power of the silicone is considerable. The adhesive is applied only on one surface, not on both of the materials to be bonded.

Step 4: Gently squeeze the items together to stick evenly. If silicone adhesive comes out, you should remove it with the spatula.

Step 5: Now let the glue dry, which varies depending on the thickness and type of silicone. On average, the waiting time can be between 24 hours and five days.

Glue silicone surfaces

Due to their surface properties, silicones can not be processed with conventional adhesives, even strong second- or all-purpose adhesives. Therefore, silicone is often used as a release layer of self-adhesive labels or adhesive tapes, as it can never be completely glued or easily peeled off. This is due to the low-energy properties of the material, which makes adhesion much more difficult. Nevertheless, there are two ways to glue the elastic fabric:

1. Liquid Industrial Silicone Adhesives : Industry uses adhesives that can adhere to silicone surfaces and can be used even in the home. It is based on alpha cyanoacrylate, an advanced form of the classic 2-cyanoacrylic acid methyl ester, used in seconds and tissue adhesives. This is used like a conventional liquid adhesive, only the silicone surface must be prepared for:

- Dust or clean

- Surface must be free of rust and grease

- To connect surfaces must be accurate, otherwise the adhesive does not work so well

- The adhesive is applied and then enriched with oxygen for one to three minutes

- then the surfaces are connected together

- The adhesive will begin to stick as soon as contact pressure exists

- after that it is dried

This form of adhesive must be applied evenly to prevent it from leaking back on the sides, which can be a problem. Fresh glue can attract dirt, such as hair or dust, which reduces adhesive power. Excess glue can be easily removed with a cutter, as long as the silicone surfaces are not damaged. A big disadvantage of liquid adhesives is the fact that they are difficult to dissolve; In many cases, not even at all, without permanently damaging the surface.

2. Adhesive tapes based on synthetic polymers and elastomers: these tapes are a product of the multi-technology company 3M Germany from Neuss, which is offered in the following versions:

- Type 91022 for low-energy surfaces (including silicone)

- Type 96042 with foil carrier

These are designed to bond together films and papers that have a silicone coating. The adhesive effect is so strong that the silicone surfaces threaten to tear as soon as they are to be released from each other again. Compared to the above-mentioned liquid adhesives, they are perfect for surface bonding because of the following advantages:

- do not run

- Adhesive surface remains even, because the tape always has the same thickness

- work with foam, rubber and rubber products made of silicone

- can be detached carefully again

- Withstands temperatures of up to 260 ° C

- can also be used for plastics such as PTFE, polyethylene and polypropylene

They are used exclusively for the silicone surfaces, which is useful for a variety of applications. It is used as conventional tape, so it only has to be removed from the tape and glued to a surface. The two types of adhesive tapes are double-sided and can even connect heavy objects such as Teflon pans with a spatula.

Related Links

Would you like to know more about the material "silicone">> acrylic or silicone?