Concrete blocks - dimensions & prices of formwork blocks

- What are shuttering stones "> Applications

- Ideas for buildings

- Dimensions

- Quality and prices

- Special features when laying

Concrete block made of concrete does not tell you very much? If you're creative, that should change urgently, with the Schalersteinen you can build more and faster than any other building material. They can also be built properly and resiliently, because they are called formwork bricks because they replace the formwork with their own concrete filling.

The concrete concrete block is a very ingenious invention that allows you to build very creative concrete structures with a minimum of effort and cost and in a very short time. Without having to deal with scarfwoods, their construction, mining, cleaning, etc., this stone could become your favorite building block.

What are shuttering stones?

If you work with concrete, you usually use a formwork, wooden boards, which must be built up and possibly treated with formwork oil (separating oil), so that concrete and formwork wood can later easily separate. In which the concrete is filled, if it is solid, this formwork is removed again.

These conventional formwork must be cleaned after removal consuming, so they can be used again. They are usually used only once or twice by construction companies, but they would have served their purpose in the private construction project anyway. Although the formwork boards (with the rarely environmentally friendly oils) will hopefully be recycled somehow, a tremendous waste of material, but mostly mineral scarf oil is used in the German construction annually about 25, 000 tons.

But there are also lost formwork, specially manufactured molds that remain in the foundation and must not be turned off, cleaned and transported away. Recently, more and more solutions are being devised in this direction, if possible even more economical and practicable for the users, such as special flat lattice mats with hinged folding system as lost formwork.

But there is already a perfect "lost formwork": Schalsteine or formwork bricks are cast concrete blocks that are laid dry and then filled with concrete, so they are, so to speak, their own lost formwork.

Concrete formwork blocks can be processed quickly and easily, have tongue and groove in the butt joints and produce smooth, closed, very fine grain visible surfaces.

applications

Concrete bricks are a very simple building material to pull up walls and walls, fast and efficient, structurally quite stable and with good building physics properties.

The stones are set dry depending on the design and surface training and bricked with mortar of the mortar groups normally used in masonry construction, possibly also with thin-bed mortar in the runners association (half offset).

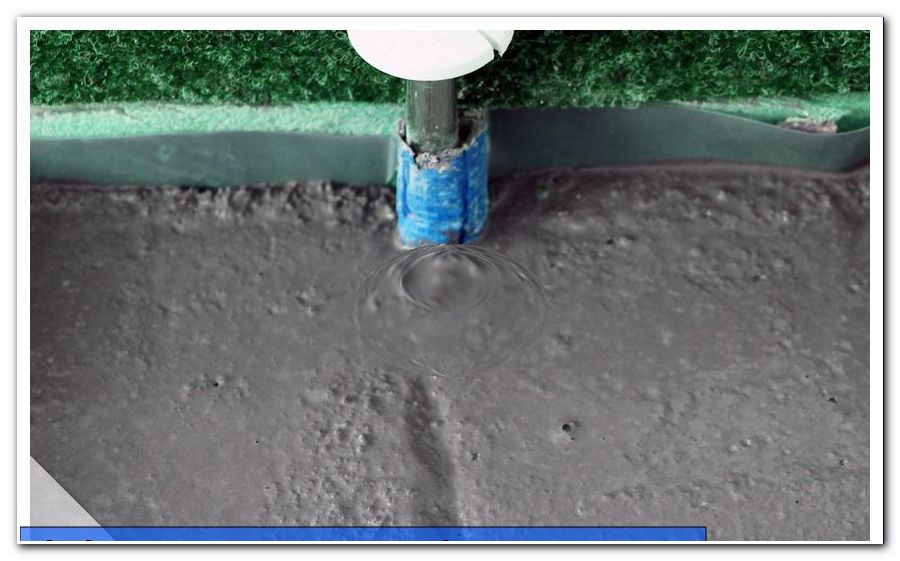

The cavities are filled with concrete, grade B 5, B 10, consistency KP (plastic), KR (soft) or KF (flowable) - according to the new DIN 1045-2, the flowability goes from F1 to F6. The cavities are either filled with fluid concrete, which no longer needs to be compacted mechanically, or filled with drier concrete, which is compacted with an internal vibrator.

The formwork blocks usually have transverse recesses through which the filling concrete flows transversely and thus connects the stones together. Depending on the design of the stones, concrete is poured layer by layer or the same for the entire structure.

The walls made of formwork blocks have a high mass with good static load capacity, the wall construction is very economical, usually neither additional reinforcement nor formwork is needed. The soundproofing of such walls is also comparatively good: A wall of 17.5 cm thick has a sound insulation index of 59 dB (for comparison: three-pane insulating glass depending on the thickness of 34 to 43 dB).

Ideas for buildings

This kind of "Lego for self-filling" can of course be used for a huge number of buildings, around the house z. For example:

- strip foundations

- Warehouses and adjoining rooms

- Retaining walls

- partitions

These are the "official ideas", but with Schalsteinen you can also do much more in the apartment, z. B. as a shelf. The stones can be changed in color or left in modern gray.

In the garden Schalsteine z. B. are used for creative privacy walls that are filled and planted in the respective upper stones with soil, for garden walls or walls in the garden area, as a garden bar and for whole bedding landscapes with pond.

Just a few suggestions that these interesting stones sure give a lot of ideas for all sorts of small buildings ago.

Dimensions

Shuttering stones are offered in different sizes:

- The stones have the standard width of 50 cm

- An offered heights are 20 cm and 25 cm (standard)

- Of these scarf stones you need 10 or 8 stones per square meter wall surface

| height | Wall thickness | Quantity of filled concrete / m² |

|---|---|---|

| 20 | 17, 5 cm 20 cm 24 cm 30 cm 36.5 cm | 90 l 120 l 150 l 200 l 250 l |

| 25 | 11.5 cm 15 cm 17, 5 cm 20 cm 24 cm 30 cm 36.5 cm 40 cm | 50 l 70 l 90 l 120 l 150 l 200 l 250 l 300 l |

The stones are each manufactured and monitored according to specific, relevant in the construction industry standards, eg. Eg here:

- Wall thickness 11.5 and 15 cm: Guideline for Non-Standard Concrete Products, RiNGB

- Wall thicknesses from 24 to 42 cm: DIN 11622 T.22: "Fermentation Silos and Slurry Containers: Concrete Formwork Stones"

- All remaining wall thicknesses: Approval Z-17.1-404 from the Institute for Construction Technology, Berlin

These were the standard sizes normally offered, there are special sizes up to the slightly round shaped stone and shuttering stones in different colors. You can ask for it in the regional concrete block factory. For the colored version, tailor-made cover plates are offered, so that you can, for. B. on a wall along a way planter can provide.

All of the just listed stone blocks are available in the most commonly used quality B25, which usually meets the requirements for small private structures.

Quality and prices

The quality

Schalsteine are offered in different concrete strength classes, B15, B25, B35:

- B15 quality is mostly used for standard applications for cellars and foundations, with normal concrete this would be about the strength class C12 / 15

- B25 quality is mostly used in the field of vision, it is highly compacted and very precisely dimensionally stable and corresponds approximately to C20 / 30 concrete

- B35 is a quality for particularly heavy loads, it is comparable in strength with normal concrete C30 / 37

The prices

The prices for concrete formwork stones depend of course on the size and the wall thicknesses. The common concrete formwork stone is the 25 cm stone, for which reason the prices of various common strengths are given below, the 20 cm stones are each a little cheaper:

The prices for concrete formwork stones depend of course on the size and the wall thicknesses. The common concrete formwork stone is the 25 cm stone, for which reason the prices of various common strengths are given below, the 20 cm stones are each a little cheaper:

- Formwork stone 15 cm from 1, 50 €, 8 pcs = 1 m² = 12, 00 €

- Shuttering stone 20 cm from 1, 75 €, 8 pcs = 1 m² = 14, 00 €

- Formwork stone 24 cm from 1, 90 €, 8 pcs = 1 m² = 15, 20 €

- Shuttering stone 30 cm from 2, 15 €, 8 pcs = 1 m² = 17, 20 €

- Formwork stone 40 cm from 3, 15 €, 8 pcs = 1 m² = 25, 20 €

If you do not want to buy from the manufacturer, but individual Schalsteine in the hardware store, you may get some rather rarely used intermediate size, rather than the manufacturer, but the prices are slightly higher:

Hornbach offers the 17.5 cm stones, which fit perfectly for some horticulture, but a stone costs 2.75 € (from 60 pieces 2.45 €). Likewise with the formwork stones 24 cm, they cost here as single stones 2.95 €.

Obi calls about the same prices for these concrete slabs in minimum order quantities, and they have the 36.5 stone on offer, for a single price € 2.99.

This results in a price for DIY store stones of approx. 22.00 € / m².

Endstones, special sizes, colored formwork stones each cost a bit (or a good deal more), and of course you have to add a possible reinforcement (depending on the static requirements) and the fluid concrete (quality also according to static calculation).

Special features when laying

Shuttering stones are to be processed without elaborate formwork, but afterwards somewhat more cumbersome when sealing. Sealing is usually necessary so that moisture does not get through the joints. For garden walls without static might not be so tragic sometimes, but that looks pretty ugly after a few years. You can seal walls in the outer area with mineral sealing sludge (sand + cement, there's in the hardware store as a powder for mixing).

The sealing slurries can be applied very quickly with a thick brush (Quast).

Tip: If there is a lot of moisture on the wall (eg mud slope behind it), then a bitumen coating should follow the sealing slurry.

reinforcement

Reinforcement is also called reinforcement and consists of a stabilization of the wall with steel. If you are planning smaller structures without a structural engineer: Even if the stones interlock with tongue and groove, in case of doubt the flat base (foundation ">

For masonry made of formwork blocks, the general construction supervision approval (depending on size) is required.

Laying and filling the shuttering blocks in a brief overview:

- Stack wall or wall of shuttering blocks

- In the masonry bandage, usually as a runners' association, where each row of stones is offset from the underlying by half a stone length

- Along a string of string put the first stone row in mortar group III

- Check with the spirit level, unevenness is compensated by moving the stones

- If the first layer is exactly straight, the next shuttering blocks can be placed dry in the dressing

- Make sure that the shuttering blocks are tight and without gaps

- Now the reinforcement is calculated, which has been calculated by the structural engineer

- This structural steel increases the strength and resilience of the wall significantly

- Before concreting, the formwork stones are thoroughly pre-wetted

- Flow concrete (to be ordered in the concrete plant and delivered by concrete mixer)

- Depending on the statics concrete B15 or B25, as fluid concrete according to DIN 1045, ENV206

- The fluid concrete is filled in by crane and concreting bucket or with the concrete pump

- Flowable concrete is self-compacting, at critical points you are welcome to compact it (poking around in the concrete with a stick)

- The flow concrete now has to harden, the final strength is reached after 28 days

flow concrete

Incidentally, you can also make on-site fluid concrete, which is simply a concrete with good flow and cohesiveness, the consistency of which is adjusted by adding a plasticizer. This is not the simplest concrete for mixing yourself, because it has to be so fluid that it compresses itself or by lightly poking, but on the other hand it must hold together so well that it does not segregate due to necessary slight shaking or other vibrations but there are also good instructions for that.

Incidentally, you can also make on-site fluid concrete, which is simply a concrete with good flow and cohesiveness, the consistency of which is adjusted by adding a plasticizer. This is not the simplest concrete for mixing yourself, because it has to be so fluid that it compresses itself or by lightly poking, but on the other hand it must hold together so well that it does not segregate due to necessary slight shaking or other vibrations but there are also good instructions for that.

According to the old, often cited DIN 1045, there were four consistency ranges: stiff (KS or K1), plastic (KP o. K2), soft (KR o. K3, soft control or normal consistency) and flowable (KF). In these old standards, the medium-consistency concrete was emphasized and referred to as Rule Consistency (KR) concrete. Such a concrete is a soft concrete that is easy to convey, process, install and compact.

The current DIN 1045 defines, like the European standard EN 206, seven consistency ranges (very stiff, stiff, plastic, soft, very soft, free-flowing, very flowable), which are very free-flowing due to spread classes (F1 stiff to F6) and densification classes (C0 very stiff to C3 soft).

If you work with the concrete, you should protect your skin and eyes and avoid any contact with the concrete as much as possible. In concrete, strongly alkaline cement that irritates the skin and mucous membranes is irritating.

Conclusion

Overall, Schalsteine are a great material for impatient people, with them you can pull walls and walls with very little effort and still has a really solid and resilient wall after filling with concrete. Here it was all about concrete formwork bricks, but today there are also scarf stones made of completely different materials, wooden shavings. B., which provide a pleasant indoor climate and energetically passive house quality, for creative homeowners this versatile stone belongs to the most exciting building materials ever.