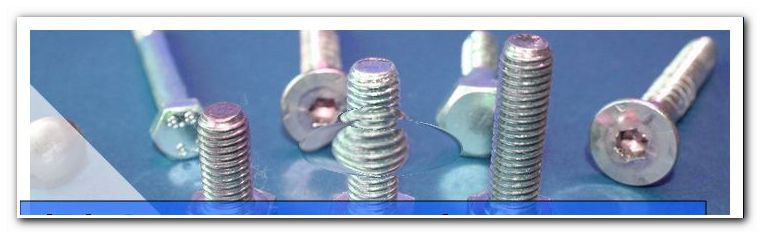

Types of Screws - Overview of the world of screws

- Shape of the shaft

- cap screws

- pointed screws

- head shape

- Geometries on the screw head

- External hexagon

- Allen

- Torx

- Device Torx

- Phillips

- slot

- thumbscrews

Screws are the standard parts when it comes to releasably joined connections. Once all the necessary through holes or threaded holes have been fitted to the workpieces to be joined, they can be permanently connected using a screw connection. With the right tool, a screw connection can always be loosened without damage.

A screw holds by a so-called positive and a positive connection. Positive locking means that the head and the counterpart of the screw connection (eg a nut or a countersunk thread) are larger than the screwed on element. Frictionally means that the screw itself sits by clamping and frictional force on its thread. The inner stretch resulting from the tightening is the force which makes the screw connection so durable.

One can already see from this explanation that the simple and everyday component "screw" is an ingenious masterpiece, which has made itself indispensable.

But when is which screw needed ">

Shape of the shaft

A screw consists primarily of head and shaft. Both are highly variable in their geometry. There are even headless screws, such as those used in some jigsaws to lock the saw blade. Important in the first distinction is the shape of the shaft.

cap screws

If it is along its thread a cylinder with constant cross-section, then it is a cylinder screw . It needs to seat a matching hole in which an internal thread is cut. This applies, for example, to most screws in mechanics.

In mechanical engineering almost exclusively cylindrical screws are used. Only at the screwing of housings can be found sheet metal screws or their variant for plastics. That is why cylinder screws are also called " machine screws ".

Screw connections with cylinder head screws must always match each other. Threading different threads inevitably leads to destruction of the entire connection. Ideally, you first use a cylinder screw by hand and turn a few threads until you are sure that the inner and outer threads really fit together.

Cylinder screws can be turned on and off as often as required, provided that sufficient lubrication is ensured and contamination of the thread is prevented.

Cylinder screws can be found on all demountable devices and machines. They are usually made of high-strength steel, but occasionally they are also made of plastic. Old nutcrackers even have cylinder screws made of wood.

pointed screws

A screw tapering along its shank cuts its thread as it penetrates into the workpiece to be screwed. Colloquially, these screws are called " wood screws ", as they are usually used for screwing to beams, boards or plates. The professional name for this type of screw are " pointed screws".

Pointed screws are used for mounting on soft materials such as wood, plastic or pressboard. Although they are solvable, the connection loses in the majority of cases, the tensile strength when repeated turning in and out of the self-cut hole in most cases.

Pointed screws are usually made of steel, which was additionally coated. Short pointed screws are also called " tapping screws " and are used for example in body construction. This includes the housing screws, as used in home appliances. They are an intermediate step between cylinder head screw and self-tapping pointed screw: In the form of a wood screw very similar, but device screws are screwed into preformed threads made of plastic or aluminum. Despite the similar shape, device screws should not be replaced by wood screws, as the internal thread on the housing can be damaged.

After the primary distinction between cylinder head screw and pointed head, there are still numerous other differentiation options for screws. Parameters for screws are:

- Dimensions in length, shaft diameter and head diameter

- Material and remuneration

- Corrosion and temperature resistance

- Tensile strength and shear strength

- backup options

- head shape

head shape

Four head shapes have prevailed with screws.

Flat head: Cylindrical shape with different geometries. Stands out at the connection. Most common head shape in the entire mechanics. Ideal for hexagon. Does not penetrate into the workpiece.

Round head: semi-circular profile. Most with slot or Phillips. It also stands out, but is visually appealing and with little chance of injury injury

Linsenkopf: Semicircular profile with conical bottom. Also usually slot or Phillips shape. Is less prominent than the round head and is therefore even less risk of injury. Very often used for tapping screws.

Countersunk head: conical bottom, flat top. The head disappears completely in the connection and no longer stands out. Ideal for places where there is a high risk of contact or technically would disturb a protruding head (eg hinges). The countersunk head is widely used with wood screws. A disadvantage of the countersunk head is the low material thickness, which can lead to slight over-tightening when screwing.

Geometries on the screw head

The geometry on the screw head determines with which tool a screw can be loosened and tightened. The professional designation of the geometry of the screw head is " drive form "

External hexagon

The hexagon socket is used everywhere where extremely reliable screw connections are required. Wheel nuts are a typical example. Aesthetics or other functionality are at the back with hexagon socket screws. They allow the highest and most defined power transmissions. The torque wrench is used for this purpose.

One distinguishes external hex between metric and imperial dimension. In Europe, the metric measure has prevailed, in the Anglo-Saxon area and in the US still imperial head measurements dominate.

Advantages:

- massive head-shaft connection with high power transmission

- used frequently in mechanics

- both from above and laterally solvable

- Insensitive to turning

Disadvantage:

- Can only be produced as a protruding flat head

Allen

The hexagon socket is also widely used in mechanics. It saves space, but can also absorb high forces. Its handling is pleasant because the key sits firmly in the head and you can concentrate entirely on the screws.

Advantages:

- Good for hard to reach places.

- Can be produced with all head profiles.

Disadvantage:

- Solvable only from above

- lower tensile forces possible than with external hexagon

- For small cross sections, sensitive to turning

Torx

The Torx is the evolution of the hexagon socket. Instead of a hexagonal inner profile, the Torx has a star-shaped geometry. This almost completely avoids slipping and turning.

advantages

- good for hard to reach places

- very tight fit between key / bit and screw

- can be produced with all head profiles.

disadvantage

- Only detachable from above

- High quality tool required

- very sensitive to turning around with wrong tool.

Device Torx

Device Torx are almost identical to Torx screws. The difference is a small pin in the middle of the star-shaped inner profile. He gives the imported key an extra grip. The key and the screw head are clamped together so that the screw is not lost when pulling out. This screw form is widely used in electrical engineering and home appliance technology. It also allows non-magnetic materials in the screws, in which a magnetic head screwdriver would be ineffective.

Advantages:

- Good for hard to reach places

- Very tight fit between key / bit and screw head

- Can be produced with all head profiles.

disadvantage

- Solvable only from above

- Special tool required

- Phillips

Phillips

The cross slot with its variants is still the standard geometry for wood screws. With high-quality and suitable tools fast and efficient screw connections can be produced. The key / bit size is not as compelling in the cross slot as in the other screw head shapes. Nevertheless, it is recommended to use a tool that fits as well as possible, because the risk of turning around - especially when using cordless screwdrivers - is very high.

One distinguishes between Phillips " Philips PH " and " Pozidrive PZ " drive types. PH screws are simple cross-slots as they are found in device screws or sheet metal screws. PZ screws have in addition to the deep cross slot another cross-shaped notch. Although this is much lower than the main notch, it gives the drive tool but a good additional grip.

This head shape is mainly used with self-tapping countersunk head screws. Wood screws are hardly produced with another drive form.

Advantages:

- Easy to use

- Can be produced with all head profiles.

disadvantage

- Great danger of turning around in case of improper handling

- Only detachable from above

slot

The slotted screw the oldest form of all screw geometries. It is simple, but today has such great disadvantages that it is hardly used, except in precision mechanics.

advantages

- With tools (coins, door keys, washers, knives) detachable

- Good for very small screws.

- Can be produced with all head profiles.

disadvantage

- Even with a suitable tool high risk of slipping.

thumbscrews

Thumbscrews have on their head two widely spaced, longitudinally threaded sash. They are designed to be turned in and out by hand.

Thumbscrews are hardly used today. Although these are easily and without tools solvable, but can only muster a very low tensile force. occasionally they are still used for parking tasks or for sealing tanks.

It can be said that Torx is likely to displace all other internal geometries. Slotted screws only make sense in the long term with very small screws. Phillips and hexagon can not compete with their power consumption with the star-shaped Torx by far.

Screws are simple but very effective fasteners. Treated with due care, a screw connection is reliable and always releasable. That's why you should always use the correct tool. Once demolished, turned round or solidly rusted, a damaged screw connection can lead to the destruction of the entire component. Therefore one should also meet these seemingly simple elements with the necessary respect.