Lay vinyl flooring - instructions and tips

- Material and preparation

- PE film and impact sound insulation

- installation Guidelines

- The planning

- Lay vinyl floor

- cut

- skirting

- Transition profiles

- The door

- care Tips

Nothing is more beautiful than a home away from home. But quickly the mood is clouded when you see here and there damage to the apartment or one of the formerly beautiful floor covering no longer pleases. If the floor is damaged or just does not look as nice as it used to be, a change is inevitable, but a new floor installation costs a lot of money. Here this DIY helps to help!

If the floor covering is damaged or no longer tolerable from an optical point of view, it is necessary to change the floor soon, especially if the flooring is damaged. Because this represents a potential tripping and accident site. If the floor laying is too expensive, only help tackle yourself. But when laying the new flooring is much to note, this DIY explains how to quickly and easily move his new vinyl floor .

Vinyl floors or also called click vinyl floors, is a type of floor covering that is laid in principle like laminate and is also quite similar in appearance. Instead of wood, this type of soil is mainly made of PVC. As with the laminate, individual floor elements are laid floating together by means of a click system . By default, a footfall sound insulation is laid under the vinyl floor. The impact sound is used to minimize the sound when entering the ground to a minimum. This is especially important in older buildings, which are very "noisy". Furthermore, the impact sound insulation serves as a vapor barrier and anti-slip mat. Depending on the manufacturer, the functions and properties of the impact sound insulation are different, as well as their type of installation and thickness.

Material and preparation

Before the actual laying of the floor can be started, some preliminary work must be done. All remains of the last floor must be completely removed. Just old carpets, which were stuck, leaving splices on the floor, these must be removed just like any other bumps on the floor. Connecting should be thoroughly sucked or at least swept.

Any irregularity in the ground would mean that the ground does not lie flat on the ground at one point. After a short time of use here would damage the new floor occur, in the worst case, there would be cracks at the joint edges of the individual floor elements or other problems. Minimal bumps can be compensated by the impact sound insulation, but here it depends on the thickness and type of impact sound insulation. PE impact sound insulation ( polyethylene ) allows for small bumps and adapts to the substrate. Cork impact sound insulation hardly allows any bumps.

Before the floor covering can be laid, the floor covering should also be stored in the room to be laid for 24 - 48 hours in order to acclimatise it.

Required material:

- vinyl flooring

- sound insulation

- PE film

- masking tape

- spacer

Required tools:

- Eisenhammer

- rubber hammer

- crowbar

- bat

- fitting wedges

- Cuttermesser

- jigsaw

- Pad for cutting

- pencil

- ruler

- Squares

- calculator

- knee pad

PE film and impact sound insulation

If the new floor is to be laid on a mineral substrate, it is imperative to place a PE film on the floor as the first layer, which serves as a vapor barrier and protects the floor from rising damp.

The PE film is laid out in the entire room, whereby at the edge of the web on the wall two centimeters should run up, here the film is fixed with painter crepe. The individual tracks are laid overlapped with 20 centimeters. The laying direction is not important.

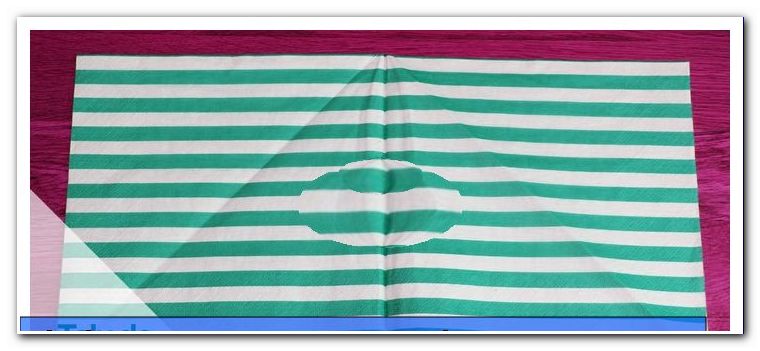

Once the PE film has been laid, the installation of the sound insulation follows, which is available as rolled and flat goods. It is also laid floating on the ground, meaning it is not fixed to the ground. The impact sound insulation is flush with the wall. In contrast to the PE film, this layer is laid in shock. The individual layers must not overlap, otherwise the ground would become wavy later.

Tip: There is also footfall sound insulation with integrated vapor barrier.

installation Guidelines

In contrast to a few years ago, where it was mandatory due to the material mandatory to lay the ground with the light, it is now apparent, whether you are laying with or against the light. Also, the laying pattern is up to the taste of the publisher.

But there are some tricks that can be used to direct the effect of space in a certain direction. In rooms in which the incidence of light comes primarily from one direction, z. B. by several windows on one wall side, the laying of the planks in the direction of the light source, it appears as if the longitudinal edges carry the light in the room, the room means visually longer. If the planks are laid diagonally to the incident light, the room, in reverse, appears wider due to the optically visible joints.

The beginning of the first row is chosen as possible opposite the door, as a straight wall as the first vinyl row simplifies the laying and one can gradually work the door forward. Whether the left or right is started in the room, specifies the manufacturer of the floor.

The planning

It is important that all bumps of the planks have at least 30 centimeters offset to the transverse joints of the planks in the adjacent rows. Furthermore, it is necessary that the first and last row of planks have a minimum width of five centimeters. On these principles, the planning of the room is made.

Lay vinyl floor

Should it be necessary to minimize the width of the planks due to the room dimensions, this will be the first step. All planks are brought to the same width.

Important: To be on the safe side, measure all walls of the room. Especially in old buildings, even in small rooms, large differences in the room dimensions prevail. This must be taken into account when cutting the width of the planks.

The beginning of the first planks is determined by the click system of the manufacturer . The example works from left to right. The first floorboard is now placed in the left corner of the room, keeping a distance of five millimeters on the left wall. Spacers are used for this purpose. Spacers are small wedges made of wood or plastic, which are available in every hardware store.

In the next step, insert the second floor board into the lock and press it downwards, then hit it gently with a rubber hammer on the lock again. It must be ensured that there is no offset at the front edges. If you do not work properly at this point, this will affect the entire floor. Lay out more and more floorboards in this row until they arrive at the other end of the room. Now shorten the last floorboard plus a distance of five millimeters and then insert it as well.

When the row is complete, the pull bar is hung on the last floorboard and gently beaten with an iron hammer to close the last gaps.

Important: Some manufacturers rely purely on click systems, other manufacturers require an additional gluing of the boards with each other at the joints. Should this be necessary, it is necessary to force the last, to be shortened board before gluing cut that a swift assembly and stick together is possible. Adhesives for vinyl floors begin to dry after just a few minutes. If you are not fast enough, emerging columns can not be closed with the pull bar. Therefore, good preparation is necessary on each series, so as not to waste time unnecessarily.

Now push the first row of planks against the wall until it is 5 millimeters from the wall. Then insert spacers at a distance of 20 to 30 centimeters. Then start with the second set of planks. There are now two different ways of laying .

Uneven joint laying

In case of uneven joints, the section of the last floorboard will be used as start for the next row. The beginning of the new series should not be less than 30 centimeters. Also, the offset between the planks should not be less than 30 inches.

- The advantage of this installation is a very economical material consumption

- the disadvantage is irregularly appearing front edges

Even joint laying

The second possibility is the even laying of joints. The front joints are aligned with each other. Every second row looks the same.

- The advantage of this installation is a harmonious joint

- the disadvantage is a significantly increased material consumption

Now lay out the rows one after the other. The last row planks should have as already noted a minimum width of five centimeters. Then remove the spacers. The floor covering should now be at a distance of five millimeters to the wall on all sides.

cut

Contrary to the laminate, the cutting of the vinyl floor is very easy. Place a stop angle at the marked point for the section and cut with the utility knife the top layer of the floor. The board can now be bent downwards and the PVC layer can be cut with the carpet knife. Roundings and smaller cutouts can be easily cut with the jigsaw .

skirting

The baseboards are chosen to match the floor. There are either baseboards made of plastic or wooden strips with the corresponding veneer. The baseboards are not attached to the floor, but on the wall. Most baseboards have an existing click system, which is attached to the wall with screws.

Transition profiles

At the transition from one room to the next, transition profiles made of metal are often used. These should never be bolted to the vinyl floor. Leave a small gap between the floor covering in the next room. Through this gap, the screws of the transition profiles are rotated. Alternatively, some manufacturers offer special transition profiles and motion profiles.

The door

If possible, the door frame should be shortened to push the vinyl floor under the frame. If this is not possible, the vinyl floor is laid with a distance of three millimeters to the door frame. The resulting gap is grouted with matching silicone .

care Tips

The surface of vinyl floors varies from manufacturer to manufacturer. In most cases, the floors are equipped with a special coating, so that a Einpflege most often omitted. If this is not the case, there are special resources that are available from the manufacturer.

Clean vinyl floors with neutral cleaners that are not too aggressive. The manufacturer is happy to help here and advises which budget funds are safe for the new soil.

Tip: objects that are often moved in the room, the chairs or tables should be equipped with furniture glides to prevent scratching the floor. Office chairs should be used on a plastic pad (office pad). Alternatively, they should have suitable roles, these are extra soft.