Glue ABS - with what and how? We show the best glue

- The best glue for ABS

- Glue ABS: Instructions

ABS, which is actually acrylonitrile-butadiene-styrene copolymer, is one of the most widely used plastics today and is used, for example, in model making, in numerous household products, Legos and computer casings. Due to their properties, ABS plastics are also an important component in the vehicle industry. Although the plastics are extremely resistant and difficult to damage, bonding ABS is not an easy task.

What makes ABS stick? "> The best adhesives for ABS

Before you can glue ABS, you should choose the appropriate adhesive. Here are several products available that can be easily applied after the appropriate surface treatment and even allow such strong connections that the plastic can not be solved. The adhesives are:

1. Cyanoacrylate Superglue: Classic Cyanoacrylate-based superglue can be used on small areas without major problems. For example, you can use it to repair models for modeling or household items, such as a small crack in the grip of a teapot. They work particularly well with parts made of brass and aluminum. For each bottle of 20 grams, about 3 euros are required.

2. Special Adhesive: Several special adhesives based on solvents that are designed for a strong hold, can stick to ABS and that quite well. An example of this is the UHU HART special adhesive, which is offered for a price of about 4 euros with a quantity of 35 grams per tube. It lends itself well to large areas and even heavier parts.

3. Assembly Adhesive: Assembly adhesives suitable for ABS and polystyrene have a very high bond strength and provide the necessary hold. Examples of such adhesives are the UHU allplast for a similar price as the UHU HART and Parabond 600 from DL Chemicals for a price of 10 euros. These immediately provide the required effect and effectively connect the individual surfaces with each other. Also available from UHU Ultra mounting glue, which is offered for a price of 5 € per 100 grams and sticks particularly strong.

4. 2-component methacrylate adhesive: These adhesives are offered by many companies and one example is the UHU plus multifest for 19 euros per 50 milliliters. Due to their nature, these provide the necessary force connecting the surfaces. After 10 to 15 minutes, the necessary strength is achieved.

5. 2-component construction adhesive (epoxy resin base): these are similar to the function of 2-component methacrylate adhesives, only they are even more effective than these. They dry within 3 to 5 minutes and are extremely durable. Such adhesives are offered by 3M under the name Scotch-Weld for a price of about 30 euros per 100 milliliters.

6. 3M VHB tapes: These tapes from the US company 3M are designed so that you can glue together high-energy materials. You can use these tapes either ABS plastics with ABS plastics, metals or other plastics connect. Best of all, it's extremely easy to use because the VHB tapes are applied just as easily as a normal tape. In other words, you can not accidentally use too much glue, which will be squeezed out at the sides, resulting in glue residue. The cost of a roll of 3 meters is about 7 euros.

Glue ABS: Instructions

Once you have decided on an adhesive, you can start gluing. All you need is the following materials:

- adhesive

- Sandpaper for roughening

- Solvents such as acetone or others based on organic substances

- gloves

Now treat the surface first

Step 1: Put on the gloves and make sure that the ABS plastic is dry. If the material is wet, allow it to dry until no moisture is left.

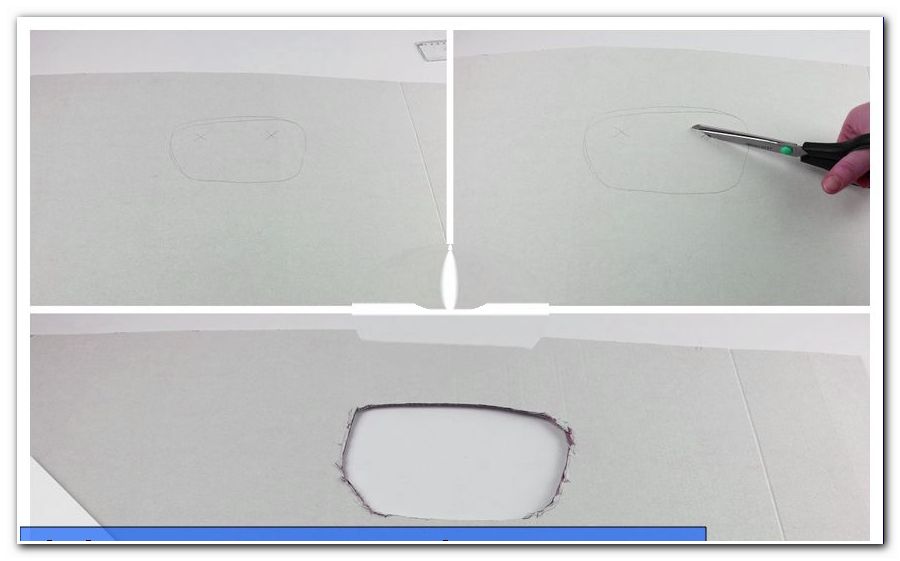

Step 2: Now roughen the surfaces of the plastic and other materials that are to be glued together. You do not have to spend much energy here, as even a little roughening effectively prepares the surface. Please note that you only have to pull the sandpaper in one direction in order to keep the adhesive surface even. This allows the glue to work better in the end. If you want to bond ABS plastics to metals, other plastics or wood, you should also roughen the surface.

3rd step: Now degreasing. To do this, take the acetone or other solvent and apply a little on the roughened surface. Make sure not to bother the unprocessed surface, as they can become too smooth otherwise. This step is also used on surfaces made of other plastics, wood and metal.

Adhesive Guide

After the solvent has completed its task, you can glue the ABS workpieces or plates. Above all, accuracy is important so that the amount of adhesive is sufficient but not too much. The following instructions will help you:

Step 1: Place the parts to be glued in front of you. Look at the size of the surface to be glued and make a mental note of how much glue you'll need to get as little glue out of the sides as possible.

Step 2: Now spread the glue in thin strips on one of the surfaces. This is best suited to the lighter of the two, as it is easier to regulate in terms of the force.

Step 3: Place the surfaces on top of each other and hold them still. The less movement the glue has to undergo, the faster it dries. For superglue you should wait a little longer because ABS plastic has longer drying times like paper or other materials.

Step 4: During the drying time you should remove excess glue with a cloth or kitchen towel while it is still liquid.

Tip: In the industrial sector, the surface treatment of ABS plastics often uses methanol and sulfuric acid acid baths. If you do not have expert knowledge about the use of these substances yourself, you should avoid this type of surface treatment, as you may be seriously injured.