Drill type tutorial - which drill bit for which material?

- General

- Drill for stone and concrete

- The right drill shank

- Drill for metal

- Regrind the twist drills

- Drill for wood

- Universal drill

To have a required hole in the right shape and at the correct position, some measures are needed. The right tool and an appropriate working method are the best prerequisites for a successful result.

Drilling holes is one of the most common engineering jobs in the industry, in the construction industry and, of course, in one's own home. Classic applications for ambitious DIY enthusiasts include installing a lamp, building furniture, hanging a mirror, or repairing technical equipment. As there is an unmanageable variety of hole drilling equipment today, we would like to give you a hands-on overview and tips on how to do it.

General

Basically, you will need a drill for this job, either with a power cord or a battery version. Since there are very individual requirements for each material into which a hole is to be drilled, these criteria must equally be fulfilled by the drilling machine. For the usual use by a DIY user in his own home, we recommend a handy and solid all-round model with the following features:

- precise drill chuck for a tool diameter of 1 to 13 mm

- electronic speed preselection and regulation

- Right and left rotation

- Impact drilling function with two gear stages

Robust branded devices can be obtained with this equipment already for around 100 euros . For frequent filigree work, an additional small and light drill may be useful. If you regularly work hard reinforced concrete or renovate exterior facades, a powerful rotary hammer will be a good investment. With these devices you achieve a very efficient work progress and they are technically designed for daily continuous operation. The corresponding costs are approx . 200 to 600 euros .

Drill for stone and concrete

For most dowel work on ceilings and walls, the so-called stone or concrete drill is suitable. Striking is the striking tip of this tool, which is formed by a wedge-shaped plate of hard metal, which is fixed there by brazing. One recognizes a good quality concrete drill, among other things, that the diameter of the actual drill is only slightly smaller than the width of the carbide insert with the two cutting edges. This geometry ensures a stable tight fit and a long service life.

For drilling in hard masonry or concrete, these cutting edges are basically made blunt and smash the material by the impact drilling function of the machine. Grinded tips are the exception and are more suitable for porous brickwork and tile material - see chapter Universal drills. The common sizes of concrete drills are the diameters 4, 5, 6, 8, and 10 mm, which are often also available as a set in the hardware store and thus fit the usual dowel sizes. Such a range of drills is already available in specialist shops for less than 10 euros .

For an exact hole position, especially in concrete, the following measures are available:

- For visual inspection, mark the middle with a large cross - 50 x 50 mm

- Grace the center with light strokes

- with small diameter, low speed and initially without Schlagbohrfunktion pre-drill

If this hole is in the correct position, you can now drill it step by step and with higher power to the desired diameter.

Note: When drilling in high-strength reinforced concrete, the bit may glow red. In this case, cooling pauses should be taken in order not to destroy the brazed connection of the cutting edge.

The right drill shank

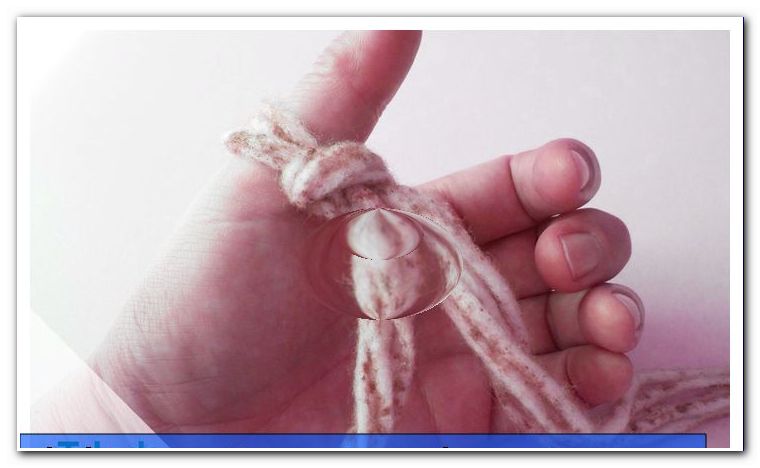

Usually, a drill has a 3-jaw chuck with quick-release or a Spannschlüssel. All standard drills with a round and smooth cylindrical shank can be picked up. This is usually enough for everyday home improvement work with the materials wood, plastic, metal and masonry. However, when drilling in solid reinforced concrete, sometimes there is the problem that the drill is blocked and "twisted" in the chuck. This can then lead to heat problems and damage to the drill and the chuck. To prevent this case, there are also positive Bohreraufnahmen. However, it should be noted that such special drills are usually usable only with the appropriate recording on the drill.

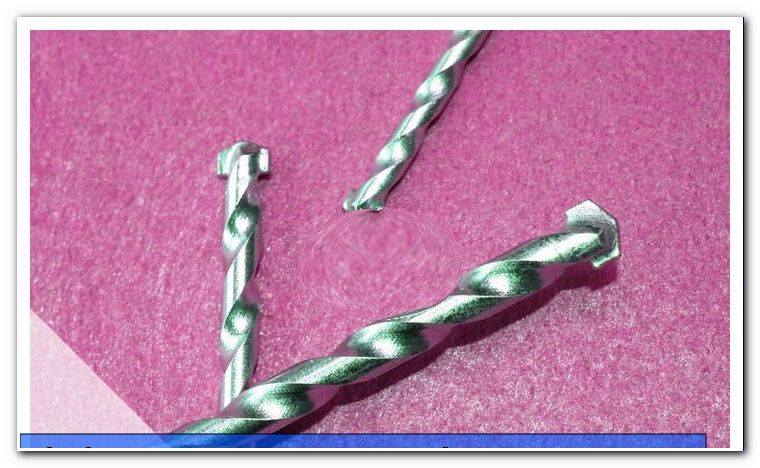

These positive drill shafts are available in the following versions:

- SDS-plus shank

- Outside edge shank in 4-edge and 6-edge design

- Straight shank with 3 chamfers

- ¼-inch hex shank

Drill for metal

For a hole in a metal plate usually used twist drills, which are also referred to as helical groove drill. The most common design is made of high-speed steel (HSS) and has a tapered cutting edge, which in turn forms an angle of 118 °. You can easily drill hard steel, softer metals such as copper and aluminum and even for many plastics and wood types can use such twist drills. These materials usually have a solid and smooth surface, which is why graining is absolutely necessary before drilling. Since home improvement is usually done by hand drilling and by eye, a careful pre-drilling with small diameters is also recommended here.

As a precaution, you should also wear protective goggles, as this cutting process produces small and sharp-edged chips. In addition, when drilling metals there is a risk that, primarily larger, tilt drill and rotate the workpiece. When drilling small sheet metal parts, there is an even greater risk of accidents due to cuts! To prevent this, you should wear suitable protective gloves while working and fix the workpiece sufficiently with a vice or clamp. For even more accurate and safe drilling, a drill stand can be used in conjunction with a machine vice. These universal accessories are available from about 150 euros in all home improvement markets and it is mainly used to perform accurate and absolutely vertical holes.

When working with twist drills, in conjunction with the appropriate materials, the appropriate speeds should be observed.

In principle, there are two rules of thumb:

- With softer materials, higher speeds are possible than with hard metals.

- With small drill diameters, higher speeds can generally be selected than with larger drills.

You can download the speed table here.

You can download the speed table here.

The right pressure

Another factor influencing the use of helical groove drills is the pressure exerted on the cutting tip. If this is too big and possibly the speed too high, the drill can start to glow and be damaged. In this "annealing" the tip turns blue, the blades lose their hardness and become dull quickly. As a precautionary measure, the pressure and speed should be appropriately selected and, in addition, a cooling cutting oil can be used.

Twist drills today are mass-produced and do not cost much. Also, they can, as already mentioned, be used very versatile. For the small diameters, from 1.0 to about 4.0 mm, it should be noted that they can break off relatively quickly in use.

This results in the following recommendations:

- in your tool cabinet is a full, 19-piece assortment with 1.0 twist drills; 1.5; 2.0 ... to 10.0 mm - costs about 10 to 30 euros

- From the smaller diameters (1.0 to 4.0 mm) you should always have an additional stock available

Of course, there are countless offers on the open market, especially for twist drills - from low-priced products to very expensive material alloys. Again, you should follow these recommendations:

- Steer clear of very cheap no-name products

- buying a well-known branded product (eg Bosch, Metabo, AEG, etc.) is certainly a good choice

- expensive special drills are usually worthwhile only if they are essential for a material and are also used regularly

Regrind the twist drills

Since the drilling of metal materials with a twist drill is a cutting and machining process, of course, the cutting edge undergoes a corresponding wear. With a bit blunt drill, one can even balance the work progress to a degree by a higher pressure. The alternative is known to be "throw away and buy new", which is often even the most rational solution, since a single twist drill does not cost much and can keep very long if used correctly. A 10-piece pack of a small drill size you get in HSS quality from just 2 euros.

Of course you can hone a blunt Wendelnutbohrer yourself and there are also various tools offered in stores. Grinders as attachments for drills are already available from 10 euros and a high-quality electric version costs for example 600 euros .

The application is "in principle quite simple", since there are usually appropriate openings for the usual drill diameter. On the other hand, you can also do a lot wrong, because with most devices, both drill bits are sharpened separately and the location of the cutting edge to the grindstone is at the discretion or the level of the user. Due to these free parameters, the results may also be correspondingly poor. For example, after sharpening the tip is no longer centered to the drill or the cutting edges have different angles. Also, a drill can quickly anneal during grinding and thus become dull and unusable. In any case, the "free grinding" of drills on a grinding wheel is only reserved for qualified specialists with a lot of experience.

The following recommendation therefore remains as a conclusion on this topic:

- If necessary, replace a blunt drill with a new one

- If you have a very high level of wear on twist drills and want to regrind them yourself, you need a professional drill sharpener and a very high degree of practice for a satisfactory and efficient result

Drill for wood

As already mentioned, holes can also be drilled in wood materials using spiral drills. This is also a pragmatic method for occasional work, in which case the usual measures should be followed:

- Mark center point generously

- Grain center

- Pre-drill with smaller diameters

- only use new or sharp drills

- Watch for sufficiently high speed

However, there are also special drills for the wood industry, which are even better suited for their tasks, than a helical groove drill. Metal products usually have a homogeneous consistency, which makes it no different for the drilling process from which side and in which direction the bore runs. Wood, on the other hand, is a natural product with fibers, knotholes and different strengths. Essentially, therefore, the classic wood drill has the following features:

- he has a center point

- the two cutting edges are almost parallel to the drilling surface

- on the outer diameter of the drill, the blades are slightly longer than inside

Equipped with these special features, the grain and pre-drilling can be omitted when working with the wood drill. After the exact placement on the marked center of the hole, the tip drills a small hole and thereby centers the drill in the predetermined position. Then first the outer cutting edges are used, which cut an exact circle into the wood surface without the edge frayed. During the following drilling process, the wood material in the hole area is then cut out layer by layer at a higher speed.

Equipped with these special features, the grain and pre-drilling can be omitted when working with the wood drill. After the exact placement on the marked center of the hole, the tip drills a small hole and thereby centers the drill in the predetermined position. Then first the outer cutting edges are used, which cut an exact circle into the wood surface without the edge frayed. During the following drilling process, the wood material in the hole area is then cut out layer by layer at a higher speed.

For larger hole diameters in wood materials one uses the so-called Forstner drill, which offers good centering even with hand-held drilling work. The similar art drills or cylinder head drills, on the other hand, are used more in the automated wood industry.

Another woodworking tool is the Flachfräsbohrer, which colloquially referred to as a spade drill . This simple and inexpensive tool is particularly popular in the DIY sector, as it can quickly and easily recesses and sink holes, for example, for hinges, window handles or door locks, produce.

Universal drill

Always using the right and appropriate tools for the do-it-yourself DIY activities is certainly the best way to work. But of course, there are other factors that play a role in the do-it-yourself hobby. In the beginning, the money is often missing or you just have on site only a small equipment. In such situations, a universal drill can be very helpful. At first glance, this tool looks like a concrete drill, but here are the two cutting edges on the cemented carbide insert now sanded. With this subtle difference, you can, in an emergency or as a compromise, drill holes in stone, concrete, metal, plastic and wood with just one drill bit. The universal drill also serves well if you have to hit a solid reinforcing bar in reinforced concrete or if you need to drill holes in old walls with integrated wooden elements.

Tips for quick readers:

- select suitable drill

- check the material before drilling

- Use the appropriate drill type

- preparatory measures: marking, graining and predrilling

- work with the optimal speeds

- Take protective measures: glasses and gloves

- replace blunt drills rather than grinding them yourself