Floating screed: definition, structure, costs and thickness

- definition

- construction

- thickness

- costs

Floating screed is a special screed form, which is also known as heating screed and is not applied directly to the substrate, but on an insulating layer. Screed forms the basis for the final flooring and serves to improve the thermal and noise insulation in the room. When using floating screed, it is important to know the composition, thicknesses and prices.

If you are renovating a room or planning to build a house, screed is an essential component, as it can be used to lay floor coverings such as tiles or parquet. A special screed form is floating screed, which is often used in house construction and is ideally used for underfloor heating and as impact sound insulation due to its insulating properties. For this reason it is also called heating screed. After laying the screed plate is "floating", that is, it is movable in the horizontal and vertical directions. When laying a floating screed, you must pay attention to several points so that it can effectively perform its function.

definition

Many people, especially do-it-yourselfers, wonder what floating screed is all about. Floating screed is a screed that is laid on the insulating layer of the floor and thus positively influences the heat and impact sound insulation. It is used very often in underfloor heating and is then called Heizestrich. Screeds on insulating layer have no contact with components such as separating rails within the floor, as this would create bridges in the sound and heat insulation, which requires a rework. Due to their properties, these screeds are better suited for small spaces, as large rooms negative on the Can affect deformation stability. Floating screeds are well-suited for do-it-yourselfers who want to install underfloor heating, as they not only keep the heat in the room and effectively insulate it, but also dampen sound as soon as the material has been laid.

construction

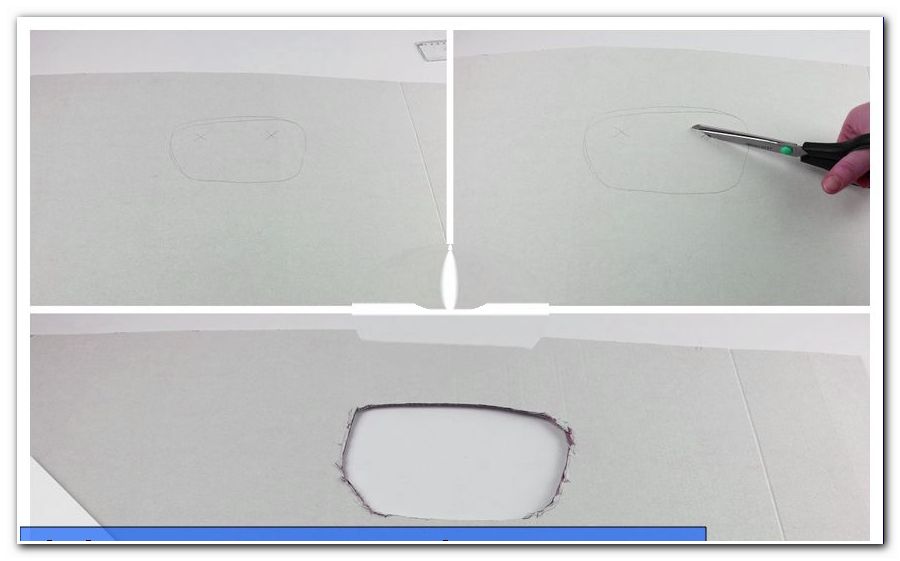

Floating screed needs a special structure due to its function as an insulating layer. This guarantees the function and stability of the soil and that it does not shift during drying. There are two different types of structure used in floating screed.

1. Without underfloor heating: Floating screed without the installation of underfloor heating is constructed as follows.

- First the floor slab is laid

- then follows the first release layer, for example bituminous membranes

- Now the insulation layer is laid

- another release layer follows, for example screed paper

- then the screed is laid

- Finally, the flooring follows

This layered construction allows the floating screed to function. In addition, a separating layer, insulating layer and separating layer are laid on the walls to hold the screed in place. These insulating strips are essential so that the screed floor can harden relaxed. Necessary expansion joints are realized via screed anchors.

2. With underfloor heating: the structure of the screed including a floor heating is designed in the same way as described above. However, the heating pipes run directly in the screed, ie between the separating layer and the floor covering. Since no components are allowed to touch the screed directly, the pipes are covered with insulating material accordingly.

Tip: The construction of screed for a floor ceiling is done in the same way, but not in wood beam ceilings. Due to the shape, dry screed is especially suitable for these.

thickness

The screed thickness gives information to you as a builder or do-it-yourselfer because it indicates how thick the floating screed must be laid. These values are defined by the DIN 18560, which deals with "screeds in the building" and should be adhered to, so that the screed can function effectively. The thicknesses for floating screeds are listed in the second part of the standard and are as follows.

1. Calcium sulphate fluid screed (CAF): A floating screed based on calcium sulphate is typical for use in homes and can easily be laid by itself. Together with CA-Estrich these are also known under the name Anhydridestrich.

The typical thicknesses are:

- F4: Minimum nominal thickness up to or equal to 35 mm

- F5: Minimum nominal thickness up to or equal to 35 mm

- F7: Minimum nominal thickness up to or equal to 35 mm

2. Calcium sulphate screed (CA): CA screed itself has the same characteristics as CAF screed, is only mixed directly on site, while CAF screed is delivered mixed. That is, they differ only in the routing, as this takes place in different ways. Therefore, the thicknesses for floating CA screeds on insulating layers are different.

- F4: Minimum nominal thickness up to or equal to 45 mm

- F5: Minimum nominal thickness up to or equal to 40 mm

- F7: Minimum nominal thickness up to or equal to 35 mm

3. Mastic asphalt (AS): As the screed is completely mixed without water, it has a completely different expansion. For this reason, the minimum nominal thickness is set to a value of up to or equal to 25 mm in the bending tensile strength class IC10. Mastic asphalt screed is used for floor heating applications.

4. Synthetic resin screed (SR): Resin screeds are an extremely expensive variant compared to the other screeds, which is especially used when short drying times are desired or none of the other screeds can be used. They are, as the name suggests, made of synthetic resins, which allow a small thickness in the individual bending tensile classes.

- F7: Minimum nominal thickness up to or equal to 35 mm

- F10: Minimum nominal thickness up to or equal to 30 mm

5. Magnesia screed (MS): Magnesia or magnesite screed is almost never used for private purposes and is particularly suitable for large areas that are not exposed to moisture.

Following the thicknesses:

- F4: Minimum nominal thickness up to or equal to 45 mm

- F5: Minimum nominal thickness up to or equal to 40 mm

- F7: Minimum nominal thickness up to or equal to 35 mm

6. Cement screed (CT): In addition to screeds based on calcium sulphate, cement screeds are the most common used in home construction or by private home improvement workers. The thicknesses for the extremely slow-drying screed are as follows.

- F4: Minimum nominal thickness up to or equal to 45 mm

- F5: Minimum nominal thickness up to or equal to 40 mm

Tip: Do not be surprised, the standard does not prescribe a maximum thickness for floating screeds. On average, this is between six to eight centimeters, is specified by the manufacturer of the screed or calculated depending on the construction project for the corresponding purpose.

costs

Floating screed belongs to the more favorable screed forms and has little effect on the total costs, especially in house construction. Of course, if you want to renovate and re-install screed completely new, the cost of the screed is generally quite low. In itself, you only have to pay attention to two costs, which work for the above-mentioned types of screed. An exception is the MS screed, as this is not actually used for private house construction, unless you have a very large property available.

The individual cost items at a glance:

1. Material: the material costs describe the cost of the screed per square meter. Since each screed has a different material composition, the prices per square meter differ accordingly.

- CA and CAF with a usual layer thickness of 4 cm: 12 to 16 euros

- CT with a usual layer thickness of 6 cm: 9 to 12 euros

- AS with a usual layer thickness of 2.5 cm: 5 to 7 euros

- SR with a usual layer thickness of 3.5 cm: 30 to 45 euros, highly dependent on the manufacturer

The layer thickness is decisive for the costs, since this changes the required volume of the screed. You'll have to weigh whether a thinner layer is more rewarding, so you can save money or, in the end, increase heating costs, for example, because the insulation is not quite as effective.

2. Craftsman: the costs for the craftsman are only available to you if you do not want to lay the screed yourself. Since screed does not necessarily take long to lay, the cost is low and in many cases, the self-laying could be more expensive because they would have to borrow the necessary equipment. For example, mastic asphalt screed should not be laid by private individuals, as the materials are heated to over 200 ° C, which is clearly too dangerous. Typical labor costs per square meter as follows.

- CA and CAF with a usual layer thickness of 4 cm: 4 to 10 euros

- CT with a usual layer thickness of 6 cm: 4 to 10 euros

- AS with a usual layer thickness of 2.5 cm: 25 to 30 euros

The labor costs of synthetic resin screeds are difficult to determine because they require a lot of work so that laying is not dangerous. For this reason, you need to explore the business directly if you want to install synthetic resin screed.

As you can see, if you have classic variants such as CA or cement screeds installed, the costs amount to 16 to 26 euros per square meter. With a typical room size of about 15 square meters you have to expect therefore with 240 to 400 euros. Often, you save money if you let the company do all the work, as all steps are brought together under one roof. If the following services are completely taken over by one supplier, you can sometimes save half of the costs.

- insulation

- screed

- underfloor heating

- Flooring

Comparisons of different providers are worthwhile with floating screeds therefore immensely.