Cellulose insulation - advantages and disadvantages + price examples

- explanation of Terms

- Production of cellulose insulation

- advantages

- Ecological insulation

- High density

- sealability

- Building physics behavior

- Fire protection

- soundproofing

- blend

- Vermin and pests

- disposal

- price

- disadvantage

- High density

- thermal insulation value

- Structural effort

- Blowing and pouring

- particulate matter

- Price - example

Whether it's the new building or the old building, every client or homeowner has already thought about reducing their heating costs or insulating their own home at least once. A good and cheap alternative, to standard insulation such as mineral wool or rock wool, which is still very environmentally friendly, is the cellulose insulation.

There are many insulation materials on the market. In most cases you are looking for a good insulating material that has the best possible and little bad properties. In addition, the insulation should also be low, non-toxic and environmentally friendly. Many clients and homeowners are also concerned about the installation. Especially mineral wool with its fine fibers is known to produce an unpleasant feeling on the skin even days later. This is where cellulose insulation comes into play. The insulating material combines many good qualities, is cheap and also made of recycled material.

explanation of Terms

The word cellulose insulation includes the main component of the insulation, cellulose. This is originally part of wood. The raw material required for the cellulose insulation is obtained mainly from waste paper, which in turn was made of wood. Accordingly, cellulose insulation is a recycled product made from renewable raw materials.

Production of cellulose insulation

Cellulose insulation is obtained from recovered paper, which comes directly from waste paper dealers, is bought by private persons or is bought by other detours. The waste paper, which is purchased only in a certain quality, is then shredded and then treated with wood and fire retardants.

By simply crushing and treating with some additives, cellulose insulation is easier and more energy efficient to produce than, for example, mineral insulation.

advantages

Ecological insulation

Cellulose insulation is ecological, because no fossil raw materials are used for production, but waste paper. This waste product thus has a second useful use. In addition, cellulose insulation is only chopped and treated with wood and fire retardants, which, unlike other insulation manufacturing processes, is very energy efficient.

High density

Cellulose insulation has a higher density than most other insulation materials such as mineral wool or glass wool. The real advantage in this is the high heat storage capacity, which is felt even in summer, since the heat of the sun from outside to inside through the wall takes longer and the rooms stay cool longer, until they are incited by the summer heat. The same phenomenon occurs in winter, where the cellulose insulation absorbs a lot of heat from the room and gradually returns it to the room when the heating is off or is being ventilated. This keeps the room warm for a longer time and warms up quickly after airing.

sealability

The fact that the insulation is blown with pressure in the predetermined area of the house, a good sealing ability is achieved. Crevices or cracks as they appear in Dämmmatten- or plates, there is not in cellulose insulation. Due to the blowing pressure, the flakes of the insulation are pressed into every corner and every corner, thus preventing heat or cold bridges.

Building physics behavior

Cellulose insulation is moisture-regulating and can absorb large amounts of water vapor without becoming "wet". Other insulations lose their insulating properties, even with small amounts of water absorption, whereas cellulose insulation does not.

Fire protection

Cellulose insulating material is in principle combustible, but by additives cellulosic insulating material is classified in fire protection class B2, which is normally flammable. Substituting cellulose insulation fire, charred only the surface. When the flame is removed, the insulation continues to glow for a few seconds and then goes out by itself. Removing the thin charred layer, the insulation is intact. Another advantage is burned cellulose insulation, it smells like burned paper, but at far less toxic exhaust gases as in other insulation. For example, in contrast to cellulose insulation, mineral wool is not flammable, but melts immediately when heated, letting the fire flow to the next building, which may be flammable. Thus, cellulose insulation provides more protection against fire.

soundproofing

The injected insulating material reduces the transmission of airborne sound to a minimum. Especially old buildings can thus benefit from improved sound insulation.

blend

Since cellulose insulation is a bulk material and is blown into all corners and corners of the insulation area, there is no waste, which ensures unnecessary costs. Only what is really consumed is paid.

Vermin and pests

Pests and pests such as mice and insects avoid cellulose due to the wood and tape protectants, which make the insulation inedible on one hand and uninhabitable on the other.

disposal

Cellulose insulation is a reusable material in every respect. So he can be sucked out of the house without problems. Returns are offered by many manufacturers. Since cellulose insulation is not hazardous waste, it can also be returned to the recycling center.

price

The deciding factor for cellulose insulation is above all the price. The fact that it is a recycled product and the production costs are very low, the final prices are quite moderate. Depending on the house and additional expenses such as additional planning or the like can be saved up to ¼ in costs compared to other insulation.

disadvantage

High density

High density

High density produces a good thermal insulation, but it has the disadvantage of high weight. The cellulose insulation material brings 50 - 60 kilograms per cubic meter, which is much more mass than other insulation. For new buildings often no problem, however, it can be a problem for renovations in old buildings, which are not designed for these loads, especially the roof is here to call, which may not carry the weight of several hundred kilograms.

thermal insulation value

Celluloredämmstoff has the disadvantage of a lower thermal insulation value compared to other insulation systems. This means that the insulation thickness must be thicker than other insulation to achieve the same insulation value. On average, the insulation with cellulose insulation must be 30 - 40% thicker. This leads to the disadvantage that either the heat output of the house is about ¼ worse than other insulating materials or you have to provide structurally for a thicker insulation layer.

Structural effort

With cellulose insulation a higher structural complexity is objectionable. For example, if mineral wool can be clamped between roof rafters and fastened with panels, the insulating room must be closed on all sides so that the insulation can not trickle out. This leads to an extra effort, on the other to additional costs in construction. This fact makes it difficult to use cellulose insulation for old buildings, especially in the attic.

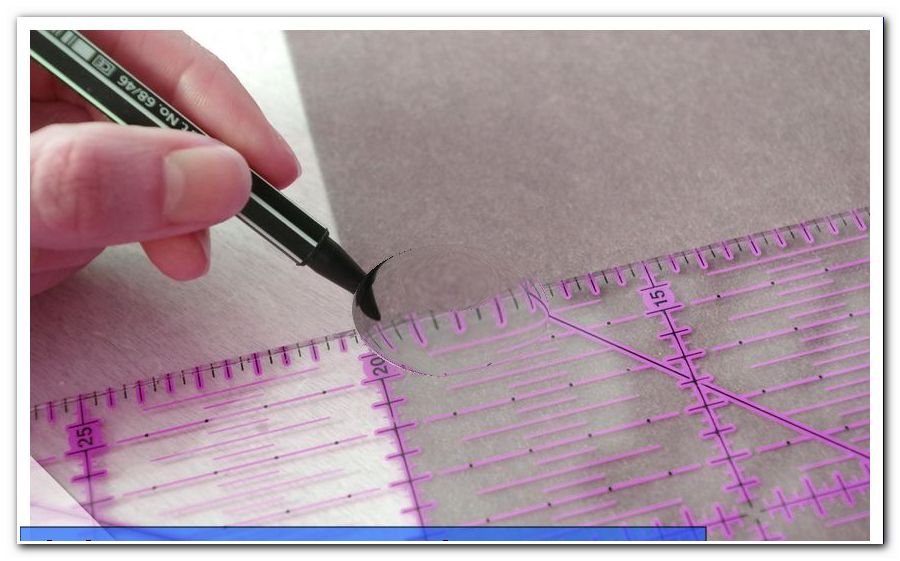

Blowing and pouring

Cellulose insulation is almost always blown with a special machine in the space provided. The advantage is that the insulation material comes to every corner. The disadvantage, however, is that such a fan for private individuals is difficult to organize and the blowing usually takes over the expert. As an alternative, cellulose insulation is also available as bulk material . The disadvantage of this, if not paid attention, arise cavities that are not insulated, heat or cold bridges would be the result.

particulate matter

Both injection and pouring can result in a high level of particulate matter pollution through the cellulose insulation. Respiratory protection should therefore be used.

Price - example

The price of cellulose insulation material varies from manufacturer to manufacturer, also the injection. As an average, with a compression of 55-60 kilograms per cubic meter, a price between 80.00 and 100.00 euros including VAT for material and fuel can be used.

The price of cellulose insulation material varies from manufacturer to manufacturer, also the injection. As an average, with a compression of 55-60 kilograms per cubic meter, a price between 80.00 and 100.00 euros including VAT for material and fuel can be used.

With an insulation thickness of 10 centimeters, this results in a price of 8.00 - 10.00 euros per square meter including VAT.

With an insulation thickness of 20 centimeters results in a price of 16.00 - 21.00 euros per square meter including VAT.

The prices are purely based on the material including the blowing. Other materials, such as wood for planking are not included.

Tips for quick readers

- advantages

- Environmentally friendly thanks to recycled material

- high density, therefore good heat storage capacity

- good moisture regulation.

- does not lose its insulating properties when wet

- Fire protection class B2 (normally inflammable)

- good sound insulation

- no waste

- cheaper than other insulation materials

- by fire and wood preservatives insect and vermin protection

- easy disposal, for example at the manufacturer

- disadvantage

- due to low thermal insulation thicker insulation layer than other insulation

- Depending on the application, a special blower is needed for blowing

- construction costs higher

- Particulate matter during filling

High density

High density