What is end grain / end grain? Advantages & prices of end grain parquet

- Endive wood vs. along wood

- Grained wood parquet

- Durability of end grain parquet

- Types and prices of end grain parquet

- Tips for quick readers

End grain or end grain is particularly abrasion-resistant wood with a characteristic textured surface. It is not a special type of wood, but describes the nature of its cut. The good properties around the abrasion resistance make the end grain especially suitable for parquet. In this post you will learn everything there is to know about the wood of the forehead.

The construction of a log

Wood grows in two ways: the tree stretches as the sun grows. At the same time it grows in width year by year. It thus generates the necessary transverse stability, which makes the length growth necessary. Otherwise it would fall over quickly or be kinked. Length growth occurs on the tree by stretching its fibers. The fibers of a tree can therefore be very long, but also very thin. The growth in width occurs on a tree but by the so-called ring formation. Every year the tree adds another outer ring to its trunk. Therefore, one can see exactly how old the tree is based on the annual rings.

The stability of wood

Wood has many very interesting properties in static-mechanical terms. It is easy to split along its fiber direction. Transversely to the fiber, it can absorb the highest compressive force. Screw connections and nails also best hold across the fiber. When screwing in screws, many fibers are stressed in the transverse direction. In the longitudinal direction but always the same fiber is injured, so that the anchor effect is low. In the longitudinal direction wood is not very absorbent. In the transverse direction, on the other hand, all the more: The pores are open and the capillary effect is fully effective. These specific properties of wood are more or less advantageous depending on the application. This must be known in the processing of end grain. Another name for this woodcut variety is "head wood".

Endive wood vs. along wood

Every normal wooden beam is one of the longitudinal wood products. He was essentially worked out of the trunk along the fiber. That makes him very resistant to bending and durable. However, it splinters and furs easily.

End grain is wood in which the surfaces are cut transversely to the fiber. Wooden boards or wooden boards, sawn transversely from a log, are typical end grain wood. Of course you can also take any trunk and cut it into small slices to obtain end grain boards. However, it will quickly be noticed that these plates fall apart easily and have little intrinsic stability.

However, end grain has certain static advantages. Since all fibers are cut through at the same time at an angle of 90 °, all chamfers are loaded equally. If the end grain can transmit a compressive force, it is very stable. This makes it very interesting for use as a parquet.

Grained wood parquet

... for tough demands

End grain parquet is a very high quality flooring. He not only offers a very appealing look. The end grain surfaces are also very resistant to pressure and abrasion. They are therefore very popular in entrances of companies or institutes, which have a high public traffic. Even shops and restaurants can get an aesthetic as well as robust floor covering with the installation of a front wood parquet.

The special aesthetic appeal of real wood parquet is due to the visible annual rings. Cut at an angle of 90 °, these annual rings are circular and produce a lively but natural pattern of the soil.

The special aesthetic appeal of real wood parquet is due to the visible annual rings. Cut at an angle of 90 °, these annual rings are circular and produce a lively but natural pattern of the soil.

However, a true end-grain parquet needs special care: untreated, the end-grain blocks are extremely absorbent. That's why parquet flooring needs to be sealed very intensively. An unsightly spotting would otherwise be the result.

However, end grain works more strongly than wood cut lengthwise to the grain. It is almost inevitable that in dry heating air during the winter months, joints in the parquet open. It therefore requires special care, especially a thorough suction is very important. Once foreign material has penetrated between the joints, it is difficult to remove it.

Durability of end grain parquet

Another enormous advantage is that end grain is a particularly durable and hard-wearing parquet. Even heavily used front wood parquet flooring can be worked up again within a few hours with the help of sanding and polishing machines so that it looks like new. The holes, bumps and stains can be easily sanded out. After the cut, however, any seal is removed. Conscientious sealing of the front wood parquet floor is therefore indispensable.

For renting a parquet sanding machine you can accept the following prices:

- Short rent (4 hours): about 35 Euro

- Daily rent: approx. 45 Euro

- Weekend rent: approx. 65 Euro

- Weekly rent: about 115 euros

Types and prices of end grain parquet

As end grain parquet, domestic hardwood is preferably used. The most common end grain material is oak. With the use of smoke or marsh oak another color accent is offered for the selection of the endowment wood flooring. Lighter types of wood for endowment parquet are spruce, pine or larch. Also available are birch, beech, maple, ash or Douglas fir. However, these usually have to be pre-ordered from the manufacturers.

The price of the parquets depends on their material, their thickness and their degree of processing. End-grain parquet pieces are approx. 25 - 75 mm thick, 4-10 cm long and 4-8 cm wide. They are cut in square shape. The parquet elements are delivered as individual blocks or as laying elements.

The following values can be assumed as guideline prices for endowment parquet flooring:

- Oak: 65 Euro / m²

- Spruce or pine: 35 Euro / m²

- Larch: 45 Euro / m²

For the installation can be expected again with about 50 Euro / m² .

The manufacturers often make special offers. End-grain wood is ultimately extracted from the remaining logs left over from the cut. That can always ensure very favorable offers.

The precious woods such as maple or beech must be ordered separately and are usually much more expensive.

Processing of wood parquet

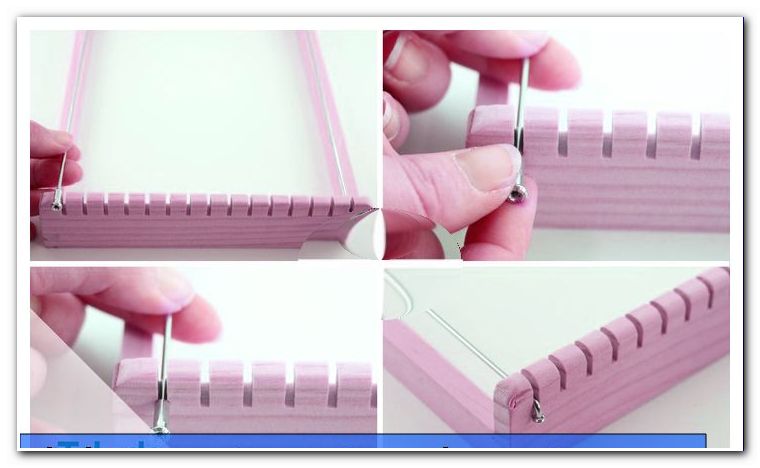

End-grain parquet is glued firmly to the substrate, then sanded and polished, thoroughly cleaned and sealed. A level and even surface is advantageous when laying end grain. The workmanship is quite laborious, because the small elements of the end grain floor make the installation tedious. When sealing you should use only high quality products from a known manufacturer.

Further advantages of the end grain floor

The end grain parquet offers a pleasant room climate, as it shields very well against the cold of the ground. This makes it less suitable for the installation of underfloor heating. This flooring also offers a high level of safety: It is extremely fire-fighting and therefore is recommended by the fire department.

Tips for quick readers

- Compare prices of manufacturers

- Sand down old end grain and work up

- Always seal the wooden hardwood floor well

- When laying yourself, pay attention to a level and even surface

- End grain is ideal for heavily used surfaces