Styrofoam cut - the simplest variants in comparison

- Facts about the cut of Styrofoam

- Possibilities to cut styrofoam

- Variant 1: heating wire cutter

- Variant 2: The knife

- Variant 3: milling machine

- Comparison of cutting variants

Styrofoam is one of the most commonly used materials in interior design, cladding, packaging and other applications. In order to achieve a straight cut and to avoid fraying and the associated pollution of the environment, there are very different possibilities and tips for simple and precise cutting.

Before you start cutting polystyrene, you should choose one of the different variants. Because for precision it is important that you process all polystyrene panels or cladding according to the same principle. Get hands-on, easy-to-follow tips for your next polystyrene cut, and be sure you're not faced with an impossible task. You do not need an expensive tool for the cut and you will be amazed at the ease with which you can cut Styrofoam to your desired dimensions and process it without any visible cutting edges.

Facts about the cut of Styrofoam

Styrofoam is known not only for many uses, but also under very different names. In the jargon polystyrene is mentioned, while in trade styrofoam, but also EPS are used as a name for this material. It is a foamed plastic whose main component is air. The production is based on the composition of numerous small beads, which are then foamed and pressed into the desired shape. This material is heat-insulating and light as a feather, but also easy to work with.

The advantageous product properties can be a challenge when cutting, if you give the right tool a minor importance. Because the sharpness of the knife or a treatment with heat are necessary to avoid a disintegration of the small globules and to achieve a straight cut in Styrofoam.

For the cut you can choose between:

- a hot wire or hot wire cutter

- a styrofoam cutter

- a classic carpet knife / cutter knife

- a sharp kitchen knife with a narrow blade

- or a milling machine

decide.

Let the desired cut straightness as well as the condition of the surface flow into your decision for a processing unit and try out the cutting technique before the actual use. The simplest variant is the one that allows you to work without difficulty and achieve the best result. It is worthwhile to try different cutting techniques and cutters, as this way you will find the perfect and suitable option.

Here you will find a detailed overview of which cutters for the processing of polystyrene can be convince and used as needed.

Possibilities to cut styrofoam

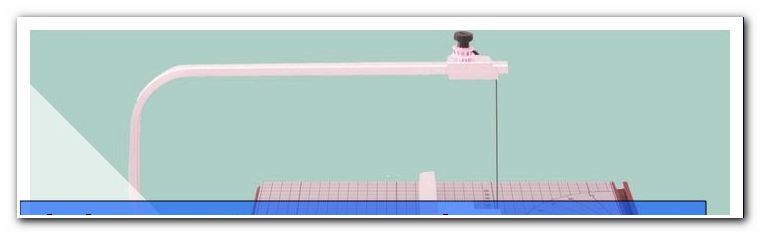

Variant 1: heating wire cutter

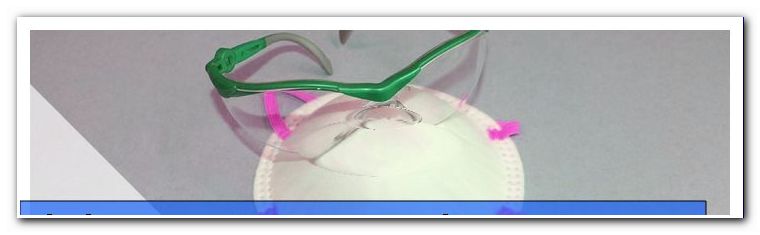

With heat especially straight and simple cuts in polystyrene are possible. It does not matter whether it is a thick panel for thermal insulation or special panels or a thin polystyrene panel, for example for decorative ceiling and wall design. The easy flammability and high melting speed of the material is an advantage in this type of processing. Styrofoam is extremely sensitive to enormous heat and melts when exposed to heat. A heated wire can be easily passed through the plastic and separates the material at the point where it is placed and fed with uniform pressure from top to bottom. It is important that you wear a respirator and do not breathe the dangerous vapors. Also, the direct contact with the heating wire must be avoided, since the adhesive residue on the wire, as well as the heat lead to burns and skin damage.

The method is particularly suitable for experienced styrofoam agents, as the heating wire or the hot wire cutter

- Fingertip feeling and

- Know how in dealing,

- as well as a steady hand

require.

If the energy supply is too high and there is too much heat, black burn marks may be left on the material. Wire processing is ideal for straight cuts to be made on long surfaces, and especially on polystyrene sheets or blocks, and light plastic strips. An individual processing with curves or recesses is not possible with the wire cut.

If an odd cut or rounding is to be generated, alternatively a soldering iron or a hot-air blower which is held by a wire held in the form is suitable. In direct contact with the soldering iron or too close to hair dryer and material there are visible burn marks and molten areas in the vicinity of the applied wire. Cut styrofoam more often and look for a practical device for professional use, you can buy a Styrocutter and use it for straight cuts and individual shapes.

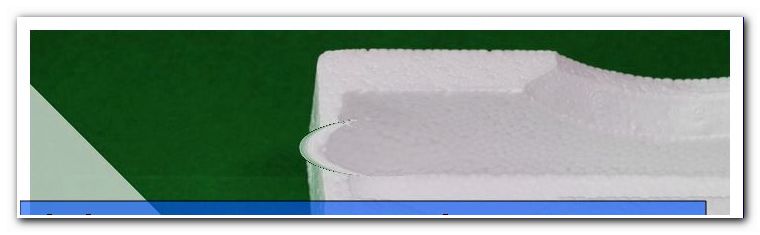

Variant 2: The knife

With thin polystyrene sheets you do not have to buy a special tool, but you can use a very simple utility knife. It is important that this knife is well sharpened and has a thin blade. As an alternative to the kitchen knife is also a utility knife, which can produce very straight cuts due to its sharp and uniform thin blade.

For the knife cut, you also need a ruler, which should preferably be made of metal. With plastic, it could easily happen that you not only cut the plastic, but also the ruler and bend its straight end by separating the smallest particles of material. You can use special styrofoam knives, although you will not achieve a significantly different result from cutting with a conventional knife. Due to the structure of the material, blades generally blunt very quickly and must be occasionally re-sharpened for a longer machining cycle. Here, Cutter prove to be a practical helper because you can break off the tip and then work with a new sharp blade.

The processing with a knife is recommended only for thin polystyrene plates and bars up to 1 centimeter thickness, but not for thicker or large blocks. The thinner the material, the more precise the result becomes when cutting with the universal or cutter knife, as well as the styrofoam knife from the hardware store.

Tip: For thicker plates, a small-toothed saw can be very helpful. If you want to machine a large amount of Styrofoam and cut it to size, a circular saw with an adjustable sawing speed can be recommended. Make sure that the speed is kept low. During very fast running the blade heats up so much that visible traces of molten polystyrene can be seen at the edges.

Variant 3: milling machine

For particularly accurate cuts and beautiful surfaces you can use the milling machine. It is important that you are familiar with the handling and can operate this machine evenly.

- Three-dimensional and completely fringe-free surfaces,

- as well as correct and

- straight transitions

are particularly easy to implement with the milling machine.

If you do not want to buy a device and pay a lot of money for processing the polystyrene, you can borrow a milling machine from the hardware store and use it for cutting. Practice a piece of styrofoam that does not depend on accuracy. After only a short use, you have found the method with which you can just make cuts and cut your styrofoam without settling. The milling machine is worthwhile only if you often cut polystyrene and it is worth the purchase for commercial use.

Comparison of cutting variants

In general, your experience, material thickness and condition, as well as the amount of blanks play an important role in the selection of a cutting technique. If you only process a few, very thin Styrofoam boards or strips, you can do without the purchase of a machine and are well-advised with a knife or a carpet knife. Even a handsaw, for example, a foxtail perform well when cutting polystyrene and convince in the processing of thicker plates or blocks. How simple the cut is and how satisfied you are with the result is your existing knowledge and skills in dealing with the chosen tool.

When working with a heating wire, for the sake of your health, do not dispense with a respirator and work outside. The right cut for any material thickness and different areas of application of your plastic sheets or blocks is also based on the accuracy that is particularly important or negligible for further processing. If you want to cover a ceiling or wall with polystyrene and thus use the material in the field of vision, straight cuts are of great importance and form the basis for a professional work and attractive appearance of the finished wall cladding.

If you lay an insulation and have opted for polystyrene as insulating material, the precision in cutting is not negligible. Nevertheless, you can work with less precision and still achieve the tightness that is necessary to lower your energy costs and maintain a constant temperature in your premises. The fact is that the right cutting technology has a lasting effect on the result and should therefore always be tailored to the application and your knowledge of how to use a tool or device.

Since Styrofoam is a very soft and light material, you will not encounter problems and difficulties when cutting. Avoid blunt knives or cutting tools, as these cause the material to crumble and, in addition to the odd-numbered cut, also result in difficult-to-remove dirt from numerous small polystyrene beads.

Tips for quick readers

- a heating wire,

- a sharp knife

- a cutter blade,

- the milling machine

- a sharp circular saw

If you need the cutting device commercially and use it for different material thicknesses, you are well advised with a milling machine or a circular saw. If you make small cuts on thin polystyrene sheets or strips, a universal or craft knife will be enough. Heating wire or a hot wire cutting machine are practical, but are recommended due to the necessary dexterity but only for experienced handyman and DIY.