Connect power cable - with / without luster terminal - instructions

- What to look for

- Power cable colors

- Connect the cable correctly

- Rigid multiple cables

- Connect with luster terminal

- Connecting with plug-in terminals

- Connect flexible power cables

- Rigid multiple cables

Power cables supply electrical outlets to sockets, lamps and switches. They are simple, insulated, multiple cables made of copper, which perform perfectly for many years. The prerequisite is that they are laid correctly. In this guide you will learn what to look for when wiring power cables.

What to look for

Hausstrom is a thing for professionals!

Make sure that handling domestic electricity (110 volts and above) is entirely in the hands of a specialist. The instructions and procedures described here are a general description and are not intended to be used by laymen! You endanger yourself and others if you work with household power cables without a certified expertise! In addition, you endanger your protection through your home s insurance!

Power cable is not the same as power cable

The primary distinction between power cables is the nature of their wires. The strand is the current-carrying core of copper, which is encased by the rubber-plastic layer. Here are basically two types:

- Rigid cables: For permanent installation in walls and along ceilings, regardless of whether surface or flush installation

- Flexible cables: For connecting electrical appliances

Rigid cables have monolithic inner cables that consist of only one strand. Flexible cables have a twisted braid of many thin cables. They serve for better handling of electrical devices. The cable does not build resistance when moving. However, the flexible cables are more prone to internal breakage. Therefore, they are not used for the wall installation. Conversely, using a rigid cable for an electrical appliance is also not allowed. During movement, a multiple cable can pull out of the connection modules. Then there is the danger of a short circuit.

Power cable colors

A power cable consists of an outer shell, through which run two or three smaller inner cables. Power cables have a filler layer of loose rubber between the outer shell and the inner cable. This filling layer is intended to prevent the ingress of water in the event of damage to the outer shell. Simple double lines without enveloping and filling layer and without color marking are only permitted for connecting loudspeakers or other low-current applications!

Permanently installed multiple cables usually have a white enclosure. Power cables for electrical appliances are usually wrapped in black. In the coloring of the inner cables they are mostly similar.

Rigid installation cables for lamps and switches are "three-core sheathed cables". Their colors mean:

- Phase conductor (phase): black or brown. The outer conductor is the current-carrying line.

- Neutral: blue or gray. The neutral conductor is the "earth". He leads the stream back again.

- Protective conductor: Red or green-yellow striped: The protective conductor is safety cable against electric shock.

Here you will find a detailed overview of the different power cable colors and their functions: power cable colors

In house installation, color is always associated with color. Be sure to pay attention. that you do not confuse the colors when wiring a junction box!

Installation cables for electric stoves have five or more inner cables. You definitely have to leave the wiring to a specialist!

Power cables for electrical appliances have two or three inner cables. It depends on their protection class, whether they need a protective conductor or not. There are three types of protection:

Protection class I: Devices WITH protective conductor. These devices can also be identified by the circle symbol with the grounding pictogram inserted.

Protection class II: Devices WITHOUT PE conductor. These devices are marked with two nested squares.

Protection class II: Devices WITHOUT PE conductor. These devices are marked with two nested squares.

Protection class III: devices with internal transformer. These devices have a detachable plug connection. This consists of only two inner cables, but they should not be repaired. In case of a defect, the line is replaced.

Protection class III: devices with internal transformer. These devices have a detachable plug connection. This consists of only two inner cables, but they should not be repaired. In case of a defect, the line is replaced.

Detailed information about the various protection classes in electrical engineering has been compiled here for you: Protection classes in electrical engineering

If a multiple cable is to be replaced, always change to the same class or better. There are also major differences within the individual types of cables: for example, irons need extra fire-resistant sheathed cables so that they can not be accidentally scorched from the outside. Similarly, highly loaded electrical hand tools require a larger cable cross-section than is necessary for the wiring of lamps. Always search for the device to be repaired and add "Wiring" or "Power Cable". This is how you always come to the right product.

Connect the cable correctly

You have chosen the right power line for your application. Now it's about connecting the wires as well. Before you even remove the first screw, observe the safety rules. That means: fuses off! It is always wired "cold". Never try to connect a cable that is live! If you are not sure which fuse is the right one, you just need to turn off the main fuse. With electrical appliances, of course, it is sufficient to unplug the plug.

Various modules are available for connecting power cables. The luster terminal has long been the standard product for this purpose. However, in many areas it is being replaced by other solutions today.

Rigid multiple cables

Connect with luster terminal

The "luster terminal" is a traditional connection means for electrical cables. It takes its name from the "chandelier, " which means "chandelier." Luster terminals are very simple solutions and are well suited for connecting rigid and flexible multiple cables. However, their installation is somewhat complex, which is why other, faster solutions in the house installation are preferred today.

The single luster terminal consists of a sleeve made of stainless steel, are screwed into the transverse two small screws. The sleeve is also covered with a characteristic plastic sheath. This plastic cover isolates the luster terminal to the outside and also protects the screws from contact. The screws are also live after connection. They also have no backup, so it must be absolutely avoided that they can unscrew by external contact again.

Manual:

You need the following tools to connect rigid power cables with a luster terminal:

- pincers

- Sharp knife, but ideally an ab insulating clamp

- fine screwdriver

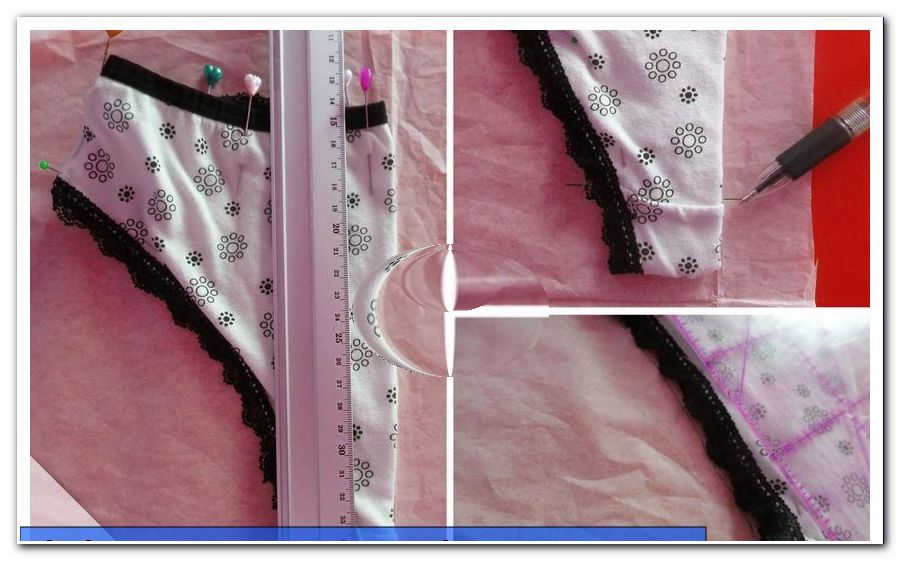

1. First remove approx. 3-5 cm from the outer sheath on the multiple cable. But make sure that the inner cables are not damaged.

2. Then feed the multiple cable through the openings to the intended location. Interior plaster cans have simple outer openings. Surface-mounted boxes have rubberized openings to the outside. The outer shell of the power cable must make a tight connection with the rubber coating!

3. Remove the insulation from the individual inner cables to approximately 2/3 of the length of the luster terminal.

4. Then loosen both screws of the luster terminal so that their thread no longer protrudes into the sleeve. But be careful not to lose the screws.

5. Insert the first inner cable into the luster terminal until its insulation has reached the first screw. Then tighten them.

6. Insert the connection cable on the opposite side in the same way. The cables will automatically touch each other in the luster terminal.

7. Repeat the process with the two other inner cables.

A luster terminal guarantees a permanent connection. It is important to keep it completely dry, as it provides no protection against short circuits caused by moisture. Luster terminals must be protected against mechanical influences. They have only a very limited resistance to train. Therefore, the luster terminals must always be decoupled mechanically to train. Never connect a hanging lamp only with the clamp! ALWAYS a ceiling hook with a matching eyelet on the cable belongs to a power line loaded with tension.

Connecting with plug-in terminals

A plug-in terminal consists of a multiple sleeve. It creates the connection by a spring-loaded blade in its interior. When inserting the line, this blade bites against the copper wire.

The plug-in terminal has displaced the luster terminals in the domestic installation as far as possible.

It offers some advantages:

- Faster assembly

- No tools needed to connect

- Very durable connection

The disadvantage of the plug-in terminal is its extremely strong connection. Once plugged in, it can only be solved with great force.

Connect rigid conductors with plug-in terminals

Here, the inner wire is stripped as far as the plug-in terminal is wide. It is ideal if the copper wire disappears completely in the sleeve and is no longer visible from the outside. A plug-in terminal has several connections next to each other and usually another on the front. This makes handling much easier and more flexible than with luster terminals. However, they are a lot more expensive: In the pack of 100, the plug-in terminals cost about 15 cents apiece.

Plug-in terminals can only be used several times. Each time the copper wire is torn out, the knife inside becomes duller until it can no longer hold a copper cable after repeating it 2-3 times. You can help in this case, to avoid another opening on the plug-in terminal. But if the circuit has to be opened regularly at this point, we recommend the luster terminals or the new WAGO terminals.

New on the market: WAGO terminals

The newly developed WAGO terminals combine the advantages of plug-in terminals with those of the terminal blocks. They look and work like plug-in terminals. The inner connection of the lines but is made by a folding bracket. This very convenient extension makes the WAGO terminal flexibly usable. Although they are again considerably more expensive than the plug-in terminals with approx. 40 cents per piece. However, they are very suitable for laymen and reusable.

Connect flexible power cables

Flexible power lines in devices such as lamps or drills have somewhat different requirements for the secure connection. These requirements are:

1. strain relief

Luster terminals are already very bad on train loadable. Electrical appliances have therefore always installed a strain relief. This is located in the housing immediately in front of the luster terminals. They consist of a bolted tab, in which the cable is inserted with its outer insulation. When tightening, the housing and the cable are connected so tightly that the current-carrying cable is relieved of tension.

2. Strand protection

The strands in flexible power cables are very sensitive. They break off easily and provide a large surface to which moisture and corrosion can attack. For this reason, a use of wire end ferrules is indicated for flexible lines. These sleeves securely enclose the thin single wires, thus protecting them from pressure and moisture. The wire end sleeve also has the correct length, with which it can be optimally connected to the luster terminals. In order to connect the stranded wire with the other end sleeve, only 1-2 mm of the tip of the cable has to be stripped.

If flexible cables are to be connected to a plug-in terminal, the wire end ferrules are indispensable.

The WAGO terminals are also permissible for multiple strands of flexible cables. However, we always recommend the use of wire end sleeves when connecting flexible cables.