Sandpaper / sandpaper: which grain size for which material

- Shape of the paper

- Structure of sandpaper

- The grain

- Scattering of sandpaper

- Which paper for which material "> Sanding

- coarse sanding

- finishing touches

- Sanding parquet

- abrasive cloth

- safety first

Sandpaper or sandpaper can be found in every workshop of a craftsman or handyman. These abrasives are among the most important tools and find multiple uses, for example, when removing paint residue, dirt, rust or other undesirable residues on different materials. Also for polishing and smoothing fine sanding papers are used. It is important to select the appropriate sandpaper for the respective application.

Sandpaper, sandpaper, glass paper or even emery paper are terms for one of the most important craft and home improvement tools. With this paper, surfaces of wood can be smoothed and sealed, old paints removed from various materials, surfaces subject to deterioration over time, polished, renewed or cleaned, welds smoothed, encrustations and debris removed on various materials, glass polished or metal separated, and others Grinding work to be performed. Depending on the type of sanding work can be used alone with the sandpaper or other aids are used, such as sanding blocks, sanding blocks made of wood, plastic or rubber, grinding machines and grinding wheels. When selecting the sanding paper, attention must be paid to the appropriate grain type, the grain size, the scattering of the grains as well as the material to be sanded and the desired sanding result.

Shape of the paper

Different sanding papers for different applications and working methods

Abrasive papers or sandpaper belong to the generally designated abrasives. In addition to the abrasive papers, other aids for grinding various materials are added, such as grinding machines with different ways to attach sanding papers on the grinding surface, sanding blocks over which the sanding papers are guided and with which then can be ground manually, as well as other tools. A simple distinction of different abrasive papers can be found in, for example,

- Sandpaper in single sheet form,

- Abrasive papers in roll form,

- Machine sanding papers,

- Wet abrasive papers and dry abrasive papers

to be hit. Sheet sanding or sandpaper is commercially available in bulk or in multi-sheet packages.

Structure of sandpaper

Sandpaper consists of different layers. On a paper layer, the so-called backing paper, one or more layers are applied with abrasives. The term "sandpaper" comes from an earlier name, as sanding grains were mainly used for sanding.

Today, the abrasive grains on the abrasive papers in the most common cases consist of corundum. Another frequently used abrasive grain is the carborundum, also called silicon carbide. These abrasives are very hard mineral and chemical compounds. However, abrasives, for example, from industrial ceramics are increasingly being used, or abrasives such as alumina, boron nitride, cubic crystalline boronite having a crystalline diamond-like structure, chromium (III) oxide and zirconium (IV) oxide and other hard abrasive substances.

Sandpaper made of corundum or silicon carbide can be easily recognized by their color. Sandpaper with corundum is available in white and pink color, silicon carbide in green or black color . Important for the quality of abrasive papers is the bonding of the abrasive particles to the backing paper. For this purpose, high quality synthetic resin is used in the most common cases. Thus, the grained abrasive can be held on the backing paper while grinding until the abrasives have been dulled by the grinding. The bonding of the abrasives to the backing paper is very important as it can significantly affect the abrasive properties and hardness of the abrasives. Inferior sandpaper can easily tear apart or lose parts of its grained layer during sanding.

The grain

The fineness of abrasive can be recognized by the grit index. The higher the coefficient for the abrasive fails, the finer it is applied as an abrasive on the backing paper. The code for the grain can be taken from the back of the sandpaper, where it is always recorded. Further information, such as the suitability of the abrasive paper for the respective different materials, can also be noted on the back.

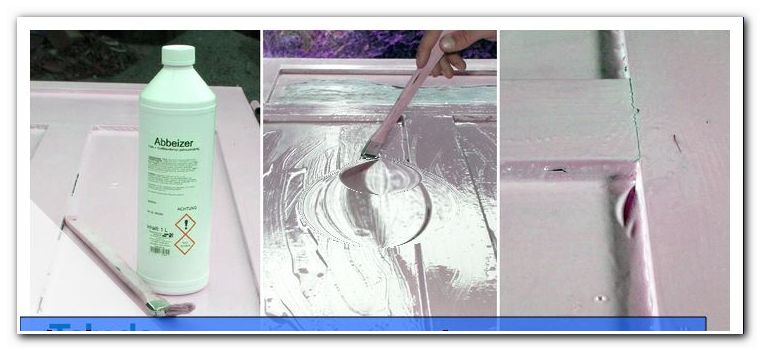

Using a coarse grit, a higher removal of the material, such as paints, glue or paint residues, dirt, rust and the like can be achieved. A coarse to medium grain size is 80 and less. The surface is heavily roughened by the grain of this sandpaper, such as in a rough pre-sanding on wooden surfaces. Grit and sandpaper with indexes between 80 and 150 are considered medium and medium-fine grits. These sanding papers are suitable for intermediate sanding, for sanding veneers or planed wooden surfaces. Primers, filled surfaces, plastics and paints should be sanded with sandpaper with fine grain size and ratios between 150 and 240. For polishing of metal, glass or dull paints by aging very fine sanding and sandpaper with grain sizes 220 and above are used.

Some common grain sizes for sandpaper or sandpaper in a nutshell:

| 6 to 30, roughly | is suitable for the removal of paints, varnishes, glue and adhesive residues as well as the like |

| 36 to 80, medium | is often used for roughing work on wooden substrates |

| 100 to 180, fine | for example, for the fine sanding of wooden substrates |

| 220 to 1, 000, very fine | for the fine grinding of pickled, primed, watered or varnished materials |

The marking for the degrees of hardness of the grain can also be preceded by letters in addition to the numbers:

- A to K indicates a soft or fine grain,

- I to O means a medium-hard grain,

- P to Z stands for a hard grain.

Scattering of sandpaper

In addition to the grain size and the respective hardness and degree of fineness, the sanding result depends on the scattering. Scattering is the type of distribution on the backing paper. A distinction is made between a closed scattering in which a dense grain exists, a semi-open scatter with a grain distributed on the backing and an open grain with grains further apart.

The higher number and dense grain provides a smoother sanding result. The disadvantage of a dense grain, however, is that the interstices between the grains can become clogged with sanding dust more quickly. Sandpaper with a less dense spread is suitable for sanding paints and varnishes. Even soft woods, which may contain a high proportion of moisture, resin or oil, should therefore be treated with sandpaper with an open diffusion. Semi-open scattering as well as closed scattering are more suitable for the processing of fine-pored woods, veneers, synthetic resin materials, plastics, metals or glass, since the sanding result is much finer than with sanding papers with open scattering.

Which paper for which material ">

In addition to corundum, alumina is the most commonly used abrasive grain. It has generally good properties and can be used on various materials, preferably on wooden substrates, veneers, paints and the like.

The silicon carbide or carborundum is called heat resistant. Sanding and sandpaper made of this material is particularly well suited for use with grinding machines.

Sandpaper with a diamond grit is the hardest. These sanding papers are significantly more expensive to manufacture than other sanding papers. The industrially produced diamonds are made of carbon, which is produced under an extremely high pressure by pressing. These sanding papers are often used for sanding metals or glass surfaces. As these abrasive papers are available in very fine grades, they are often used for the finishing and polishing of objects.

Very, very fine sanding papers can be used manually - ie by hand - also in various craft work, such as in jewelery production. Even dirt or encrustations on pieces of jewelry can be very carefully removed with very fine sandpaper. Subsequently, the jewelry should be polished with a suitable polishing cream, such as silver plaster cream or the like.

Boron nitride has almost the same hardness as a diamond. Its outstanding feature is the high heat resistance. This heat resistance is even higher than diamonds. For this reason, sandpaper or sandpaper with a grain of boron nitride is preferably used in special applications with grinding machines.

Wet abrasive papers are often also provided with a very fine grain size silicon carbide abrasive grain. Wet sanding papers, for example with grain sizes between 2000 and 5000, can be purchased commercially. With these sandpaper small defects, such as dust inclusions or the like, from the top coat - the top coat - be removed. Subsequently, the surface should be polished with a high-gloss polish at the ground point. So the faulty spot can be repaired invisibly and the former high gloss of the surface returns.

grinding gears

In order to obtain an optimal grinding result, it is usually ground in several passes. Grinding should then be done from abrasive passes with abrasive papers in at least three different grain sizes.

For example, coarse sanding of lacquered door frames or windows could be done with a 40-grit sandpaper, then the middle sanding passes are done with 80, 100 or 120 abrasive papers and finally used for finishing 180 or 220 abrasive papers, Likewise, the scattering of the various grinding operations is to choose open or tight.

Tip: For an optimal sanding result, the sanding effect should be explored on different materials with different sanding papers. The right combination of sanding papers for the different sanding processes know experienced craftsmen and do-it-yourselfers from experience. In case of uncertainty about the right composition, the specialized trade also advises.

For example, to obtain a smooth surface on different materials, the following different grain sizes could be used:

coarse sanding

| Sanding paints | 180 grit |

| Repairing paints | 120 grit |

| Removing paints | 40 grit |

| hardwood | 60s grain |

| softwood | 60s grain |

| veneer | 240 grit |

| stole | 60s grain |

| stainless steel | 120 grit |

| Remove rust on steel | 40 grit |

| aluminum | 80 grit |

finishing touches

| Sanding paints | 400 grit |

| Repairing paints | 240 grit |

| Removing paints | 80 grit |

| hardwood | 180 grit |

| softwood | 240 grit |

| veneer | 320 grit |

| stole | 240 grit |

| stainless steel | 240 grit |

| Remove rust on steel | 120 grit |

| aluminum | 240 grit |

Sanding parquet

The choice of different grain sizes when sanding parquet could for example be as follows:

1st grinding cycle

- newly laid soil - 40 grit,

- old parquet floor - 24er grit,

- old plank floor with paint -16er grit

2nd grinding cycle

- newly laid floor - 60 grit,

- old parquet floor - 40 grit,

- old plank floor with paint - 40er grit

3. Sanding

- newly laid floor - 100 grit,

- old parquet floor - 60's grain,

- old plank floor with paint - 60 grit

4th grinding cycle

- newly laid floor - not necessary

- old parquet floor - 100 grit,

- old plank floor with paint - 100 grit

abrasive cloth

Abrasive cloth is used for machine use, for example in the belt grinder. Here, the carrier layer of the abrasive grains consists of linen. This has the advantage that the linen fabric is more resistant than paper as a substrate and does not tear or wear so quickly. When sanding with angle grinders but rather sanding or sandpaper is used again. The size of the commercial angle grinders is uniform, so that sandpaper sheets or roll sandpaper can be easily clamped in the equipment.

Sandpaper with a carrier layer made of paper is also often offered for work with the orbital sander. However, working with an orbital sander is much more effective and pleasant with an abrasive cloth, as paper sandpaper can wear out very quickly in this machine.

safety first

Precautions and precautions when working with sand or sandpaper

Where sanding occurs, chips are created. Likewise, a great deal of heat can be produced by grinding on different materials. For this reason, certain precautions and safety regulations should be observed. Protective goggles, gloves and possibly other protective clothing should be worn for personal protection of the craftsman or handyman from injury. When grinding with machines, the respective safety instructions should be observed.