Wallpaper OSB panels: instructions + important tips

- Design OSB boards

- 1. fillings

- 2. grinding

- 3. Reinforcing

- 4. Priming

- 5. Gluing and wallpapering

- 6. Swipe

- Lacquer and varnish OSB boards

- Conclusion

- Related Links

The OSB plate has experienced a change. Previously, the shavings were just waste, but today they are being discovered for ever more demanding applications. Pressed into plates and glued, the OSB board has already caused a sensation in the packaging industry. With their help, the production of inexpensive but very robust transport boxes was possible. But you can do much more with OSB. We will inform you in this guide how to wallpaper OSB boards.

Even in the construction industry, the coarse chipboard was already convincing and often replaced the expensive plywood formwork panels. As a building material, it has long been popular and well-known in the USA. For about 15 years, these panels are also pushing into the shell of modern houses. It convinces with a low weight, quick and easy processing and a low price. But their usability has limits. If it is to function as an intermediate wall, not all aesthetic pleasures find themselves in the confused, brown pattern. Papering them is a viable solution here. But that's a bigger challenge than you think.

OSB versus plasterboard

Here, the coarse chipboard compared to the Rigips panels have significant advantages: You need no complex stand. A single OSB panel can already make an effective partition if it's thick enough. In order to get on the usual construction dimension of 11.5 cm minimum width, just as many plates are screwed together. Compared to the plasterboards, the OSB panels are much more stable and also offer effective sound and heat protection. In terms of fire resistance, the chipboard must give the incombustible plasterboard beaten but. Their biggest disadvantage compared to the flat, flat plates of fine anhydrite is their extremely rough structure. To make up for this, a lot of preparation is necessary.

Design OSB boards

The pronounced structure of coarse chipboard makes them even for Raufasertapeten not really usable. The surface of the wooden panels would also push through the roughest woodchip wallpaper. It is therefore essential to smooth the OSB board beforehand.

The fastest, cleanest and easiest way to smooth an OSB board is to simply dress it with an outer layer of plasterboard. This even gives you a double benefit: The fire protection is a little better with a coating of plasterboard. When plasterboard only the screw holes and joints must be filled, already the surface is ready for wallpapering.

However, if you do not want to screw an additional panel of Rigips to the OSB wall, all that remains is to level and smooth the rough-chipped surface. For this you need:

- Plaster repair spatula (Ponal / PUR spatula, approx. 5 Euro / 400g tube)

- Deep reason for wallpapering

- Wallpapering ground (about 10 Euro / 450g package)

- Wallpaper paste (about 5 Euro / pack)

- Cleaning cloth or fleece (about 1 Euro per meter and 25 cm width)

- Paste brush (2 Euro)

- bucket

- spatula

- smoothing tool

- Sandpaper, grit 80 and 100

- Sanding block or grinding machine

1. fillings

The filler is mixed according to instructions. Then you pull the mass with smoothing chip and hand spatula on the wall. It only depends on producing the smoothest possible and even surface. It does not have to look good (yet). The benefit of trowelling is not only the creation of a smooth surface but also the closing of the porous structure of the OSB board. It will make you less "thirsty".

2. grinding

After the putty has dried and cured for 4-5 hours, it can be sanded. When mechanical grinding remember to connect a vacuum cleaner. Sanding putty generates a lot of dust. You should not breathe it, but suck it directly off while sanding. A respirator makes this work particularly well tolerated.

3. Reinforcing

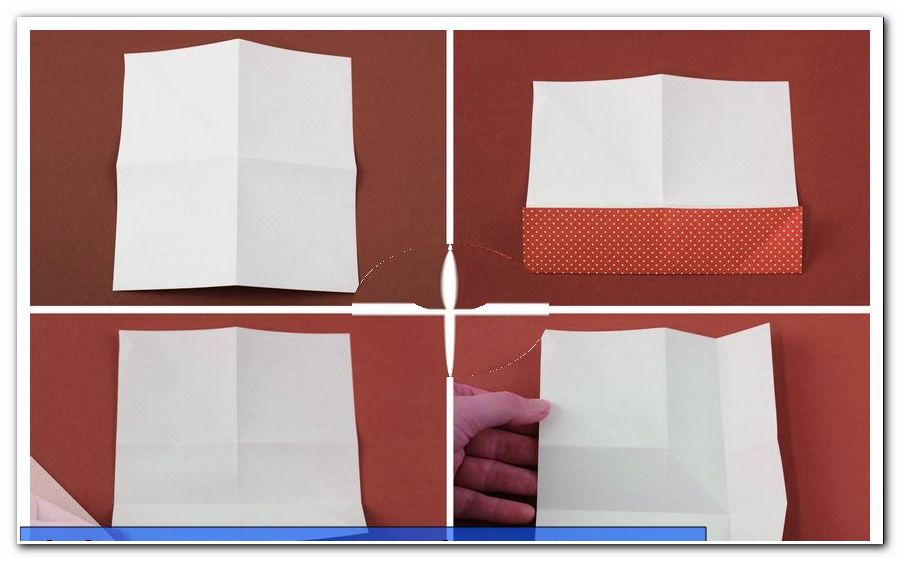

OSB boards are inserted into each other by tongue and groove. At the seams, the plaster and later also the wallpaper can tear. Therefore, the entire surface must be reinforced with the universal fleece. The cleaning fabric or fleece is simply spread with the filler over the entire surface. Ideal is an overlap of 50% from train to train. The plaster is filled with filler. Now it is important to create an even surface. Each bump, which will now translate, will later pass through the wallpaper. If necessary, the grinder has to work again after arming. The wall is left to dry again for 24 hours.

4. Priming

After the wall has been smoothed and reinforced, the primer is applied. This ensures that the wallpaper sticks well on the plate. The primer is simply applied with a puff. However, this work is very dirt-promoting: the drops of primer cure. Therefore pay attention to clothes that can subsequently be thrown away. Also, all surrounding furniture, windows and extensions should be well covered. As long as the primer is still liquid, he can simply brush away with a rag. The primer is allowed to dry out according to the manufacturer's instructions.

5. Gluing and wallpapering

The wallpaper is cut into sheets on a papering table and well pasted in. Then the wall is gelatinized, so that the wallpaper can be optimally moved. Wallpapers are always glued together on impact. They then create an even structure without seams.

6. Swipe

If no structure or motif wallpaper was used, painting can now be done. Always pay attention to the cloister: With a cross-shaped paint you can achieve optimal coverage and thus the best results.

Lacquer and varnish OSB boards

The filling, filling, arming and priming, however, is such a complicated and expensive affair that we would like to advise the plasterboard. Instead of having to wait elaborately for the drying times of filler and primer, the plasterboard is ready for wallpapering in just a few minutes. But one can also quite enjoy the rough structure of an OSB board. Then there are four ways open:

- paint

- resinate

- glaze

- To brush

In any case, you have to factor in a lot of material. OSB boards are extremely "thirsty". This is especially true for painting. For OSB panels, Bootslack is ideal. It darkens the light shavings again approximately close and can underline a pleasant, organic structure. When painting, however, it is important to pay attention to well-tolerated material. After painting, intensive ventilation is required for at least one week. Boat paint is quite expensive but produces a very scratch-resistant surface. Thus, the OSB board can also be used as a floor covering.

Instead of painting, the plate can also be glued with 2K epoxy resin. This is more economical because the viscous epoxy can not penetrate so deeply into the OSB board. The seal is durable, but not as scratch resistant as boat paint.

Tip: OSB boards always have one unprinted and one printed page. Even if the number columns only occur sporadically, they can significantly tarnish the impression of a beautiful curtain wall. When installing the intermediate walls, make sure that at least the last layer of OSB board is turned to one side. However, this only applies to OSB boards, which should only be painted on both sides.

When glazing a surface, usually wood, only lightly painted with paint. The underlying material should shimmer through a bit. This gives the surface a sophisticated look.

When painting, finally, the whole area evenly or creatively painted colorful. The advantage of OSB boards is that they begin to swell very slowly when wetted. This is, in addition to their stability, a significant advantage over the MDF. This can swell greatly during humidification. However, OSB boards can be easily painted with inexpensive emulsion paint. You can achieve spectacular effects by stroking an OSB panel in two colors. A base color is applied deeply and firmly, so that especially the chips from the second and third layer are painted over the entire surface. Afterwards, lightly stroke the plate for a second time with another, expensive, color. A rubber roller is ideal for this: it gives the paint on the surface, but does not penetrate into the deeper layers. The result looks really spectacular.

Conclusion

Fast wall, elaborate wallpapering

OSB panels are sound absorbing, insulating and fast as well as inexpensive panels. They have a tongue and groove edge, which makes them very useful especially for roof cladding and floor coverings. When it comes to disguise or creative design, it can present its structure through exciting contrasts, subtle glazing or with a coating of clear lacquer. If the record but as anonymous room wall appear, it must be additionally smoothed. The easiest way is an extra layer of plasterboard. The alternative is an elaborate filling, grinding and arming, which takes several days. The OSB board is also still very easy to work after editing: Drilling and sawing is also easy with the fixed wall. Subsequent installation of doors, windows and passages can be carried out at any time.

Related Links

You would like to know more about the building material OSB "> Dispose of OSB boards