After so many days screed is walkable - tips and hints

- Typical dry times

- Determine residual moisture

- Shortening the drying time: Tips

- Exception: dry screed

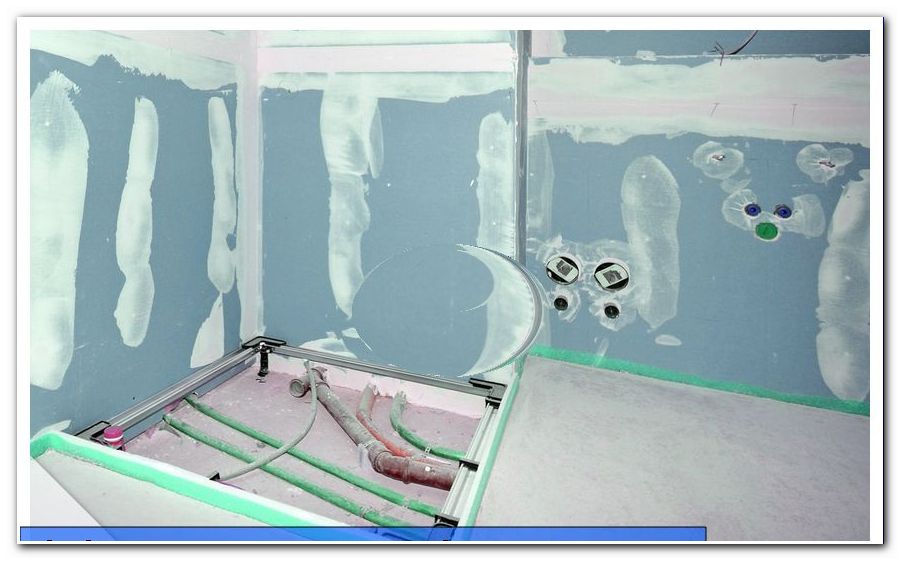

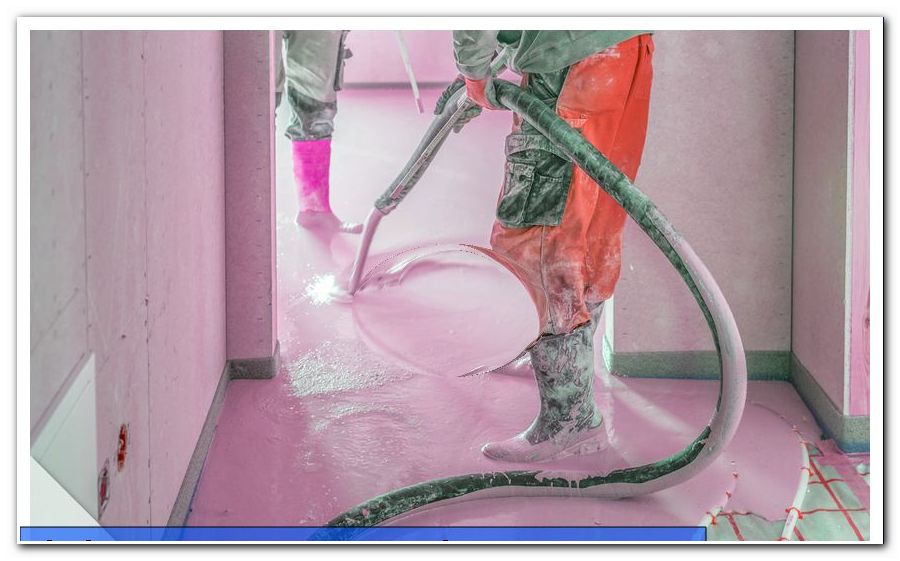

When building a house, renovating or modernizing living spaces, screed is an indispensable basis for numerous floor coverings. Several steps are used and different standard values have to be taken into account, so that the screed floor can be easily used at the end. One of the major problems for many builders or do-it-yourselfers arises in the drying times of screed, as these are not firmly standardized.

The question of when screed is accessible, employs many home improvement workers who want to renovate the floor of a living room or reduce the costs of building a house with an own contribution. As screed is a mortar that is applied directly or on a release layer, it must of course, like other types of mortar, dry before use. However, since there are different binders and manufacturers, the respective duration differs according to which the floor is accessible. If the drying time is ignored, stresses such as steps or a ladder cause great damage, making expensive repair necessary. For this reason screed must be dry.

Typical dry times

To determine whether screed is passable or not, several factors must be considered. First, the difference between a walkable screed and its full load capacity must be clarified. On a walkable screed, you can move as long as you do not run or jump, for example, as this would over-steer the force distribution to one point, resulting in increased tension and thus displacement.

The full load capacity, however, describes the condition of the screed once it has dried completely and can be loaded with high weights, for example, the entire floor covering including furniture. The typical screed types for living rooms differ significantly in the dry season.

- Cement screed: walkable after 7 to 21 days, fully loadable after six weeks without underfloor heating

- Calcium sulphate screed: walkable after 48 - 72 hours, fully loadable after a maximum of about 28 days

These guidelines can of course be influenced by a variety of influences, including.

- Temperature in the room

- air circulation

- Thickness of the screed layer

- Volume of the screed layer

- Composition, as this may vary from manufacturer to manufacturer

- installation method

- Form of aftertreatment

- improvements

- Use of binders

- Use of drying accelerators

For example, a screed will take longer to dry if it is cooler in the room than 13 ° C and also no fresh air reaches the screed. It should also be noted that screed dries from top to bottom. This means that when you have finished laying the screed and it dries, the surface can be firm, even though the screed itself is not yet accessible.

This in turn can lead to big problems because the screed then needs a post-processing, through which you have to wait even longer to complete. With the use of agents such as drying accelerators, you can greatly influence the drying process.

Tip: For cement screed, make sure to keep it sufficiently warm and airy over the cold season. If the temperatures are too low, it often happens that the screed does not dry for months, which will noticeably delay the construction project.

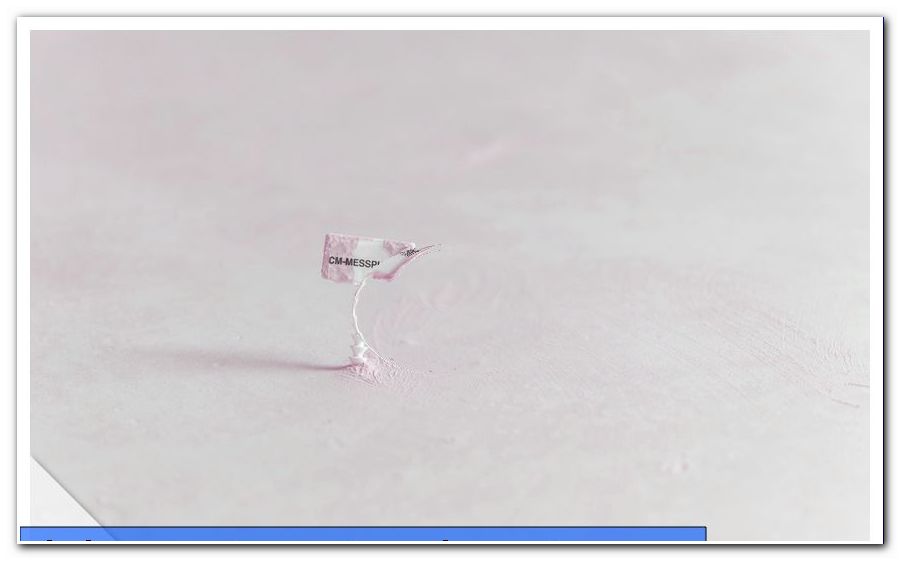

Determine residual moisture

An important step after the drying time is the determination of the residual moisture, as this gives an insight into the possible stress of the newly created soil. Above all, the so-called document maturity is tested. This designates the possibility of occupying the screed with the floor covering, without this being attacked by the moisture or the screed floor is damaged.

Likewise, the residual moisture provides information about whether the screed is passable or not, without you taking the risk to postpone it. This sample is carried out using the calcium carbide method, which in itself should be taken over by a specialist firm, since the measuring instruments are very expensive and are not worthwhile for the handyman. A measurement for a room costs depending on the provider between 75 and 100 euros.

Tip: Alternatively, you can try the so-called fingernail test to check the residual moisture, but you only get an inaccurate result. For this purpose, carefully insert a fingernail into the screed and, depending on accessibility, the fingernail sinks deeper without resistance.

Shortening the drying time: Tips

If you are in a hurry, for example, if a construction project could be completed cheaper due to possible cost savings, or winter is just around the corner, it may be a good idea to shorten the drying time of the screed.

For this purpose, various devices are available:

- drying equipment

- adsorption

- dry blower

Of course, such devices are in most cases not financeable to do-it-yourselfers unless you can lend them. There are some tips that will shorten the time considerably.

- Ventilate in the room only one day after spreading the screed

- As a result, the mass settles better and can thus dry through faster

- set up fans in the doors and open the windows

- This increases the air circulation, which speeds up the drying process

- at a temperature between 13 ° C to 30 ° C screed can effectively dry

- Therefore, in the winter, it is essential to ensure a sufficiently high temperature

- Never exceed the 30 ° C, otherwise there will be cracks in the ground

Although you still have to wait a long time for the screed with these methods, it does not take as long as without these measures. Be careful when performing these steps so that you do not expose the screed to excessive temperature changes, which could have a negative impact on the floor. If you install screed while installing underfloor heating, you can also enjoy a shorter drying time as it can even be switched on during drying.

Exception: dry screed

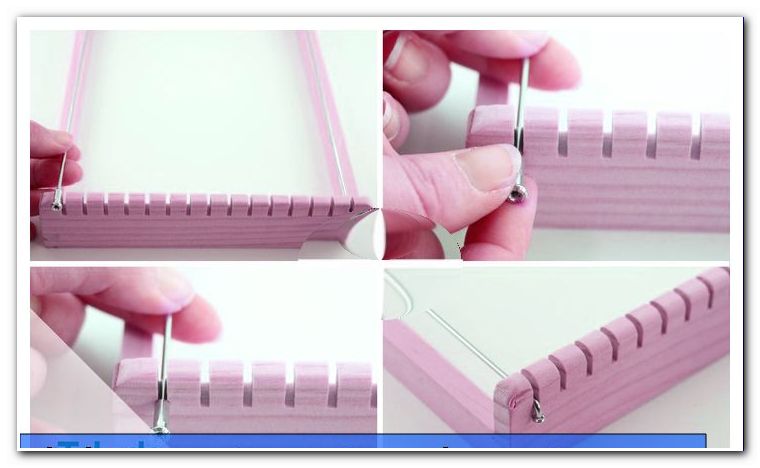

Apart from the above-mentioned types of screed there is still so-called dry screed. This is not a liquid mortar that has to dry out over time, but finished gypsum fiber or OSB boards . These are used instead of the classic screed as a base for the floor coverings and not poured, but laid and either screwed or glued with glue. This makes the use for many home improvement particularly easy because neither stirrers, air dryers or other devices are used. In contrast to liquid screed dry screed offers some advantages, but is much more expensive to buy.

- walkable immediately after installation when fastening with screws

- walkable after six to twelve hours when glued with glue

- does not have to dry out, so it can be charged immediately

- even point loads are not a problem

- For large rooms, a time saving of several weeks

- no longer dry season in winter

The only disadvantage of dry screeds is the fact that they are not used with all heating systems. But if you are looking for a fast method with little effort, dry screed is your choice. The only thing you have to pay attention to is the drying time of the glue, which is specified by the manufacturer and does not really take long because of the small thickness.