Multiplex panels - features, dimensions and prices

- comparison

- Construction of multiplex

- quality levels

- Prices

- Advantages of multiplex

- processing

- Quick tips

Multiplex panels - when portable surface is needed. Multiplex belongs to the family of plywood panels. These panels are wooden materials, which are characterized by particularly large formats and high stability. They are ideal for load-bearing and stressed structures. Compared to the slightly cheaper chipboard, they have a few more advantages. This guide completely explains the characteristics and prices of multiplex panels.

comparison

Difference multiplex to other plywood panels

Like all plywood boards, these wooden materials consist of layered and glued solid veneers. Foreign substances (except for coating, if applicable) are not used in the manufacture of multiplexes or other plywoods. The distinguishing feature of multiplex from other plywood varieties is that being exclusive

- Fully glued veneers

- stacked veneers

- Veneers with equal thickness

- At least 5 layers of veneers

- Veneers of a maximum thickness of 5 millimeters can be used

Cross laminated timber, for example, uses layers of over 5 millimeters. Wooden sticks are glued together next to each other. Veneered plywood has only 3 layers and composite plywood also allows the use of wood chips.

Construction of multiplex

Multiplex panels are at least 12 millimeters and a maximum of 80 millimeters thick. They consist of several layers of equally thick veneers. The wood types alternate. The veneers most commonly used for this purpose are birch, maple, spruce and beech. The individual layers are glued together crosswise. The number of layers is always odd. The minimum number is five layers. This achieves maximum rigidity in each bending direction. It also maximizes dimensional stability when shrinking or swelling individual layers. This makes this material well suited for areas with large temperature fluctuations or high humidity. If too much wetness is involved, however, additional measures for impregnation are recommended. As a waterproof binder phenol, Rhesorcin- or melamine resin is used in these glued plates. Veneered panels made of multiplex are offered in different quality levels.

quality levels

The sheets are bleached in quality grades A, A, AB, B, BB and C. This means:

A: Completely knotless plywood in both cover layers, minimal inlets of colors, top layers bright.

A bleached: top layers of bleached plywood, absolutely free of branches in the top layers, no enemas of colors, very bright

AB: Branch-free, light plywood in the cover layers with minimal color infiltrations. Some, healthy ingrown branches are permitted, but very rarely.

B: cover layers with small, not failed branches. Branches are firmly overgrown. Paint enemas are allowed. The knotholes may have up to 8 millimeters in diameter. Kittstellen are allowed.

BB: Big branches, knotholes and paint enemas are allowed in the cover layers. Small cracks in the cover layers are also possible. Tufts on cracks and knotholes are allowed up to a diameter of 15 millimeters.

C: Any kind of knots, knotholes, broken branches, cracks and all other natural defects are allowed as long as the stability of the plate is not affected. Not all defects need to be repaired, troweled or cemented.

The quality designation always refers to the front and the back. The quality level B / C means that small branches with a maximum diameter of 8 millimeters are visible on the visible side. The reverse side may have large optical defects, as long as they do not affect the technical capacity.

Prices

The prices of the multiplex veneer sheets depend on their type of wood, their thickness, their quality level and their after-treatment. The higher quality wood used, the thicker, higher graded, and more intensely treated a multiplex plywood panel is, the more expensive it is. The thinner, the more defects and the coarser it is, the cheaper it is traded. One distinguishes between peeled veneers and sliced veneers. In peeled veneers, the entire stem is processed in a spiral cut to a long, coherent veneer sheet. In the case of sliced veneers, the trunk is peeled off layer by layer in the longitudinal axis. Sliced veneers are more complex to process, but offer interesting visual effects. The prices given here are only average values or estimated prices. Depending on the market situation or provider, they can fluctuate by up to 30%.

Typical prices per square meter

Mulitplex plywood panels made of beech outside and inside, quality grade B / C

The beech multiplex plywood panels are very tough and robust materials. They have a waterproof bond and can therefore also be used for outdoor products. Popular applications with these panels are the manufacture of workbenches, garden furniture or equipment.

- 15 mm thickness: 35.50EUR / sqm

- 20 mm thickness: 47, 50 EUR / sqm

- 25 mm thickness: 58.50 EUR / sqm

- 30 mm thickness: 70, 50 EUR / sqm

- 40 mm thickness: 94.50 EUR / sqm

Mulitplex plywood panels made of beech outside and birch inside, quality grade A / B

These are very popular plates for the production of custom-made furniture. They are characterized by high strength and hardness combined with appealing looks.

- 15 mm thickness: 55.50 EUR / sqm

- 18 mm thickness: 57.50 EUR / sqm

- 24 mm thickness: 72.50 EUR / sqm

- 30 mm: Thickness: 87.50 EUR / sq. M

- 40 mm thickness: 119.50 EUR / sqm

American maple multiplex plywood panels, grade A / B

Maple boards are very noble and high quality. They are mainly used for furniture, kitchen and counter construction. These panels are high strength and durable.

- 15 mm thickness: 65, 50 EUR

- 18 mm thickness: 67, 50 EUR

- 24 mm thickness: 84.50 EUR

- 30 mm thickness: 98, 50 EUR

- 40 mm thickness: 130.50 EUR

Birch multiplex multiplex plywood panels, grade BB / BB

These bright panels convince by both optical and technical properties. Pricing, they are well below those of other variants. They are thus suitable as high-quality lumber or for successful equipment of workspaces.

- 6.5 mm thickness: 17.50 EUR / sqm

- 9, 0 mm thickness: 22, 50 EUR / sq.m.

- 12 mm thickness: 26, 50 EUR / sqm

- 15 mm thickness: 31, 50 EUR / sqm

- 18 mm thickness: 34, 50 EUR / sqm

- 21 mm thickness: 40, 50 EUR / sqm

- 24 mm thickness: 45, 50 EUR / sqm

- 27 mm thickness: 54.50 EUR / sqm

- 30 mm thickness: 60, 50 EUR / sqm

- 40 mm thickness: 94.50 EUR / sqm

- 50 mm thickness: 135.50 EUR / sqm

Oak plywood multiplex quality grade A / B

Unlike birch panels, oak panels have a much darker color. They are high-strength and have a particularly robust surface. They are especially popular in furniture making in the catering industry.

- 15 mm thickness: 65, 50 EUR / sqm

- 18 mm thickness: 67.50 EUR / sqm

- 24 mm thickness: 81.50 EUR / sqm

- 30 mm thickness: 96.50 EUR / sqm

- 40 mm thickness: 129.50 EUR / sqm

In addition, there are a myriad of other variants of multiplex panels. Pearwood, cherry or even poplar are used for the production of these practical and easy-to-mold wood materials.

Advantages of multiplex

As with all plywoods, the approach in the crossed and glued manufacture of these panels is to balance the disadvantages of monolithic solid woods. This is achieved by the selection of different types of wood and their crossed gluing. Cracking is therefore largely excluded with plywood in the multiplex process. Therefore, thin-walled plywoods can certainly take up their formability and tear resistance with rolled sheets of light metal. For this reason, veneer plywood was still standard for aircraft construction until the middle of the century.

Multiplex plywood panels can be produced in almost any size. The layered and cross-linked construction also allows interruptions in a cover layer. For veneer layers larger, one-piece surfaces can be produced. In contrast, knife-veneered layers allow very interesting optical effects. Particularly popular are the reflections, in which two sections are glued mirrored side by side.

The plates are much more resistant to bending than wood chipboards. These must be made very thick for a reasonable transverse stability. Veneered plywood panels require significantly less wall thickness, since the fibers are not interrupted within a single layer. Nevertheless, multiplex panels are priced in the economic context, so that they can often be a high quality but only slightly more expensive alternative to the pressboard.

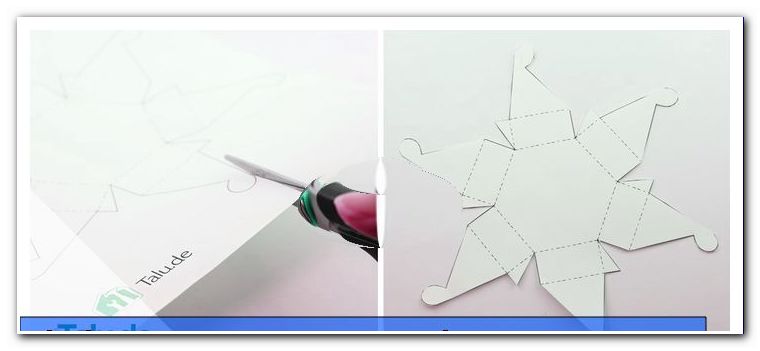

processing

Multiplex plywood panels are best processed by all laminated wood glue materials. They are easy to saw or mill. The monolithic surface makes them particularly good-natured for finishing. Grinding and polishing works well with multiplex. Subsequent aftertreatment by oiling or painting can produce very high-quality surfaces. However, in the point of bending, multiplex plywood panels are not as good-natured as normal and, above all, thinner veneer plywoods due to their high thickness and many layers. So if a curved surface is desired, it is better to dodge on thinner material.

In the case of coating processes, multiplex plywood panels have no restriction. They can be coated with all permissible procedures for wood-based materials or visually enhanced. The wide range and wide range in price makes the multiplex plywood panels suitable for any purpose in furniture making or interior design. Due to the high strength, especially in terms of bending stress, these plywood boards are also used in the packaging of high quality products. Mechanical engineering uses multiplexes and veneer plywoods as standard in international shipments.

Quick tips

- Mulitplex plywood panels are available in a particularly wide range

- Branches and knotholes can achieve interesting visual effects with clear varnish or oil

- Always plan your boards economically to minimize waste

- High-quality tools are just as important as high-quality construction material

- Multiplex as packaging material is easy to reuse