Metal rust: 7 ways to effectively remove rust

- What is rust "> Genesis

- Sanding and priming

- rust converter

- Abrasion-rays

- Dry ice blasting

- Chemical derusting

- electrolysis

- Cutting and welding

Even if slightly rusted sheet metal parts are in fashion as a garden decoration, rust is an unpleasant thing. It gradually decomposes every part of iron. Until then, he produces a lot of dirt and does not look pretty. Rust should therefore be removed at the first sign. The longer you wait, the more work you have.

What is rust?

Iron is extracted from the mine in the form of iron ore. The iron ore is a piece of rock, to which iron oxide adheres. In the blast furnace, the iron oxide is reduced to iron with the help of coal dust. Two oxygen atoms migrate from the iron oxide to the carbon atom. When smelting, carbon dioxide and pure iron are produced. The iron is liquid due to the high temperatures and runs out of the blast furnace after tapping.

formation

When rusting now exactly the opposite way happens: The iron reacts with the atmospheric oxygen and slowly transforms back to rust. Iron grate unfortunately has the unpleasant property of becoming very loose, crumbly and porous. This differentiates it, for example, from aluminum oxide. This forms a closed, airtight layer and thus stops the further oxidation process of its own accord. However, if one is not active with iron, the entire component eventually disappears to brown dust from rust.

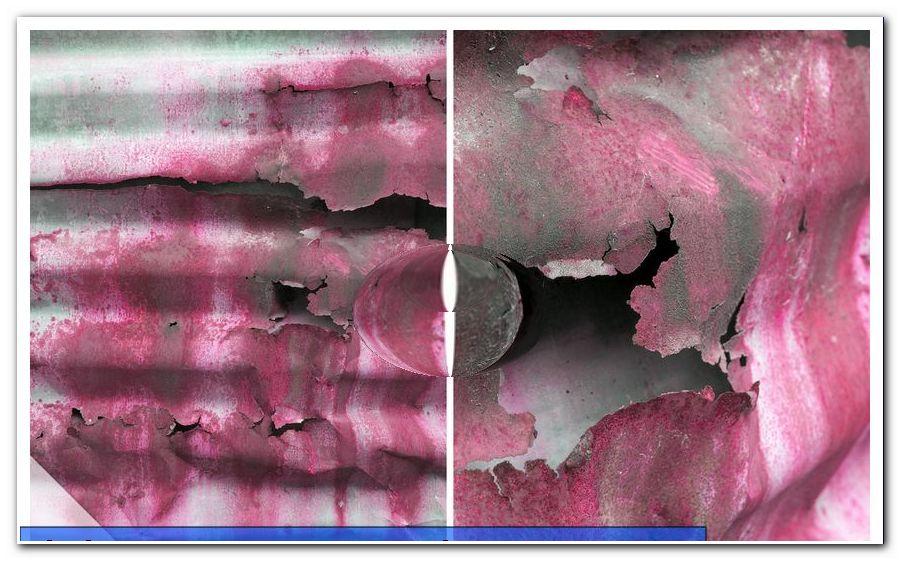

Metal rust

Seven ways to the stainless component

When removing rust, it depends on the eye and on the experience. Depending on how big and, above all, how thick the component is, there are different methods for metal rust removal . If you choose the wrong procedure, you either work yourself to death or in the worst case, you can destroy the entire component without a problem.

Therefore, before rusting, three questions should be answered:

- How big is the component ">

- Sanding and priming

- rust converter

- Abrasion-rays

- Dry ice blasting

- Chemical derusting with vinegar and baking soda

- electrolysis

- laser

Sanding and priming

The classic: sanding and priming

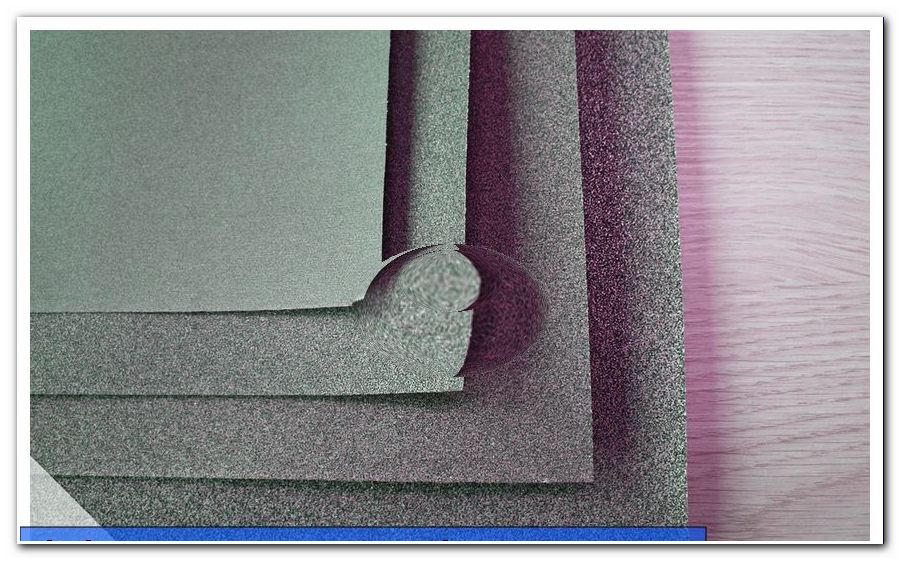

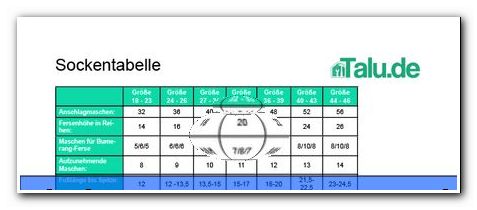

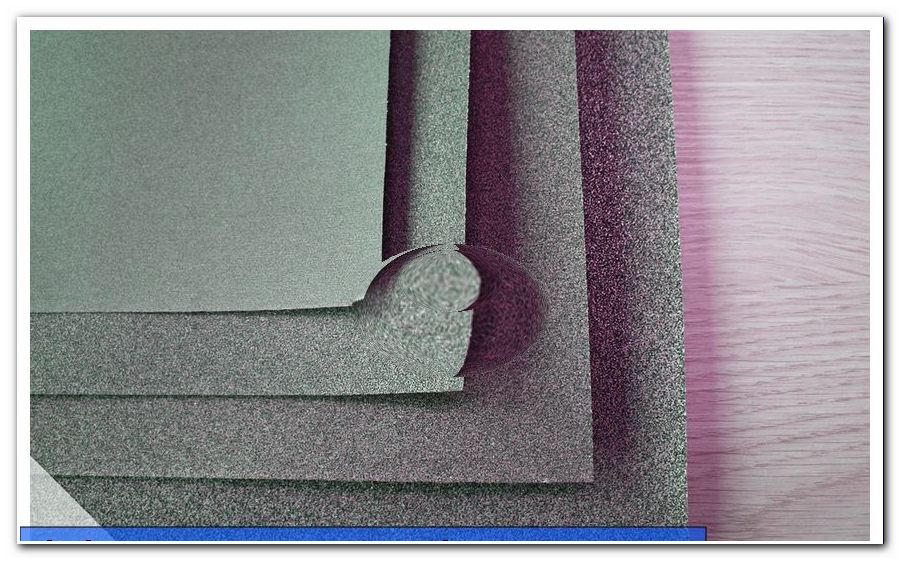

The grinding of rusty places is the classic. For light rust, fine-grained sandpaper is well suited. Depending on how big the rusted area is, you take correspondingly coarser sandpaper . But if things get too complicated, you can continue to work by machine. Sheet metal rusting works well with a belt sander, an orbital sander or an orbital sander. If the surface is irregular, take a drill with brush head attached.

After grinding, the component is cleaned with compressed air and brake cleaner and then immediately sealed with primer. Then you can paint it and it shines again like new.

rust converter

Rust converter or stain

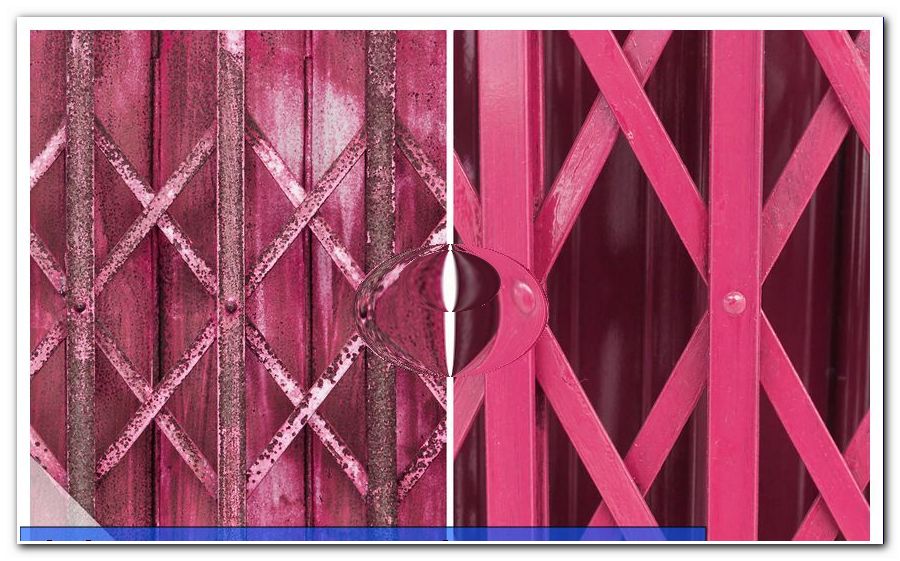

The rust converter is a chemical that stops iron oxide from further rusting. Rust converter is indeed not optimal for surface metal rust. But it is a good way to make sure during a grinding process that you have overlooked no rust nests. With rust converter, for example, ground areas on a body are aftertreated before priming. So one is sure to include no rust and get a new rust nest under the paint.

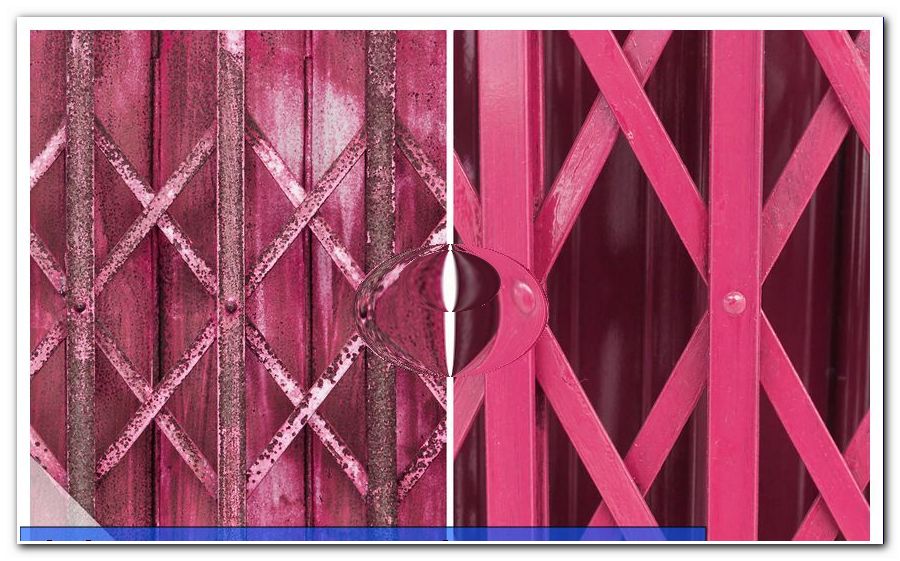

Abrasion-rays

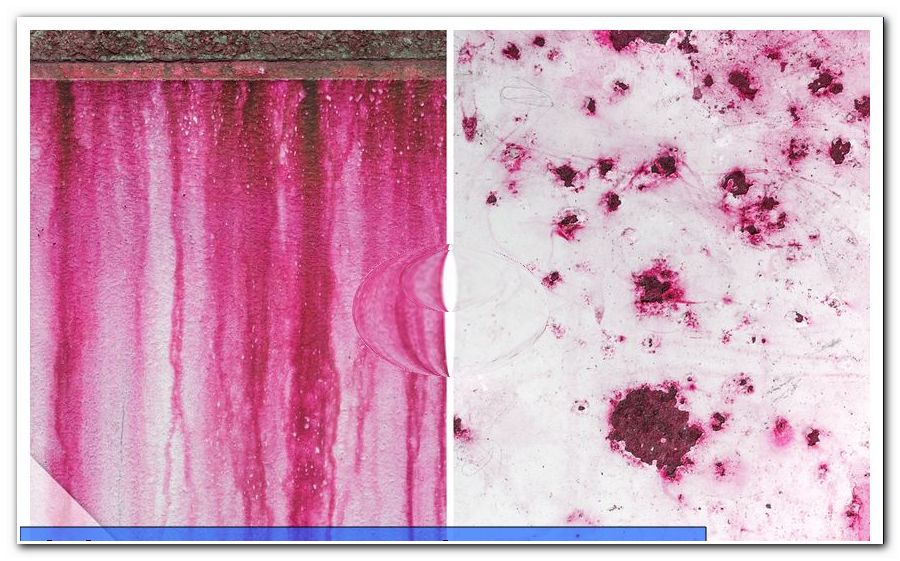

Abrasive blasting is the bombardment of a rusted surface with a hard granulate . Depending on the thickness of the component and the degree of rusting different granules are available. The spectrum ranges from relatively soft baking powder or walnut shells to super-hard quartz sand. Abrasive blasting is suitable for heavily rusted single pieces or for larger surfaces. But you have to really take care here: It is already so many beautiful vintage cars under the merciless sandblaster unrettably disappeared.

Dry ice blasting

Dry ice blasting is very similar to abrasive blasting. However, it is much gentler for the healthy basic material. Instead of hard granules, dry ice blasting is done with frozen CO2 pellets. The pellets evaporate abruptly as soon as they hit the surface. They tear loose material, including the rust. Dry ice blasting is extremely loud and quite expensive. But for vintage cars it is a very gentle process.

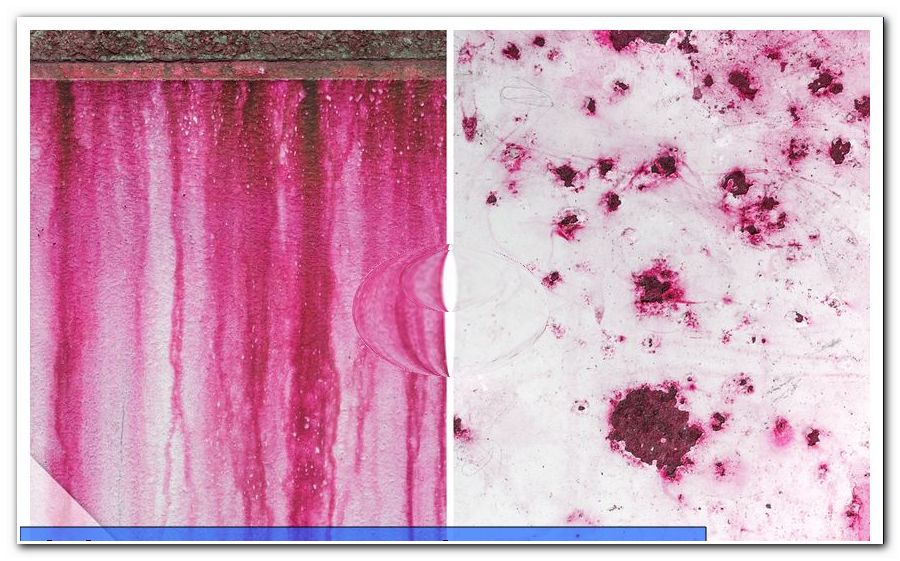

Chemical derusting

Chemical derusting with vinegar and baking soda

Rusty tools, screws or hardware made of iron can be very well de-rusted in a bath of vinegar and baking soda. The iron oxide enters into a chemical bond with the vinegar and the baking powder and thus stops the further oxidation process on the component. The metal rust removal with vinegar and baking soda has only one drawback: It is quite slow. If you are in a hurry, you can choose a particularly clever procedure.

electrolysis

Metal rust removal with electrolysis

The electrolysis is the metalworking by electric current.

For this one needs:

- 1 full car battery or a car battery charger

- 1 piece old sheet metal

- 1 plastic tub

- wire

- Washing soda or baking soda

- 1 wooden slat

The tub is filled with water and added 5-6 tablespoons of washing soda or baking soda. The bar is placed on the tub. The old piece of sheet metal is hung on a wire in the water. Likewise, the component to be rusted is hung on a wire and allowed to fully immerse in the water.

Now it says: Do not make a mistake! The RED PLUSPOL is connected to the wire to which the old piece of sheet metal hangs.

The BLACK MINUSPOL is connected to the wire to which the component hangs where you want to remove the rust. Now the charger is switched on or the battery is connected correctly.

Soon it begins to bubble on the component, where you want to remove the rust. Caution: The bubbles are pure hydrogen . Best to perform this procedure to metal rust in the open air! After a few minutes or a few hours, remove the rust. The component is taken out, cleaned and immediately sealed . As a first measure goes for WD-40 or another oil.

But please pay close attention: If the poles are confused, exactly the wrong thing happens: The old sheet metal part is clean and the component that you really wanted to rust, continues to rust. So it's better to stay with it and control where the bubbles rise.

Metal rusting with electrolysis is a very exciting experiment, especially for children and adolescents. Seeing the rusty spots vanish magically is truly mesmerizing.

Cutting and welding

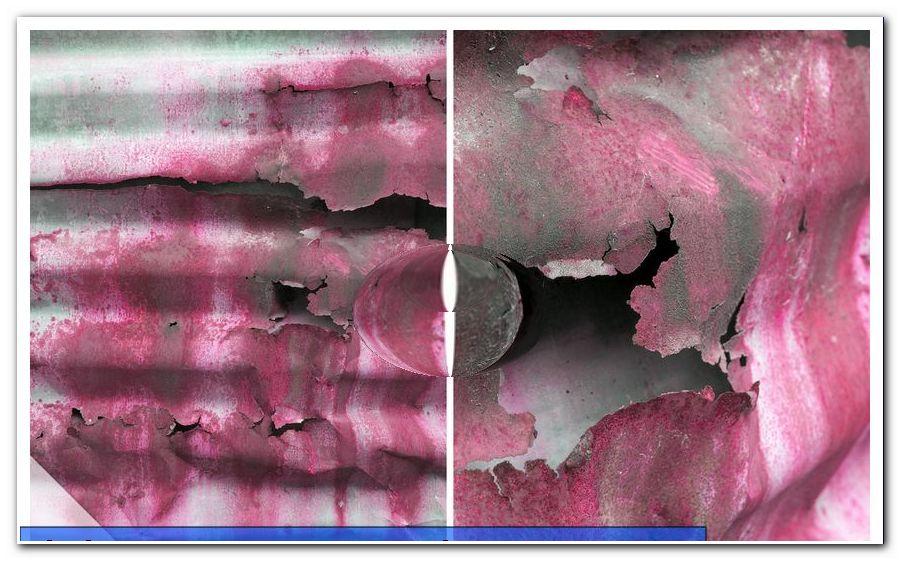

If nothing else helps: cutting and welding

If everything is too late, all that remains is to cut out the rusted area and replace it with a new piece of sheet metal. As far as you should not let it come. Therefore: Always be active before the gnawing rust has destroyed the beautiful component too much.

Do not forget to seal!

As soon as bare iron gets wet, the oxidation starts again immediately. Light flash rust can be seen very quickly, rust scars are back after a few days. Therefore: Do not stop to remove rust, but seal the component with oil, anti-rust paint, primer or a layer of plastic powder. For example, moisture and oxidation no longer have a chance to gnaw at the component.

TIP: With these tips you can quickly and very cheaply assemble a great tool collection. Convolute of rusty wrenches, pliers and saws can be found for very little money on the Internet. But if you then rusted and maintained, you quickly have a great and very nice tool set together. So you can save a lot of money and is prepared for any repair case.