Bend the copper pipe yourself - Instructions for thin-walled pipes

- When do I need a bending machine "> bend copper tube

- manual

- Cold bending with a bending machine

- Turn copper tube with bending spring

- Turn a spiral

Copper pipes can be bent in different ways. It is possible to bend the pipes in cold as well as in warm condition. In contrast to many other components is a relatively soft material, so that with the right tool, a deformation by hand is possible. Learn in our guide how to proceed in detail when cold bending.

Copper pipes are used, among other things, in the field of sanitary installations and must here be brought to the right shape. It is crucial to create the right shape and at the same time not to damage the material. Since many craftsmen shy away from deforming the pipes, they work alternatively with fittings or fitting pieces with the desired angle. Modern bending machines have contributed to the fact that in recent years, the bending of the pipes has increasingly prevailed. The advantages are that you work with fewer individual tubes and thus save connections. Each connection represents a potential weak point, whereby the bending has clear advantages.

When do I need a bending machine?

When can I work cold and without a bending machine?

If you work without a bending machine, then you must pay attention to the following factors:

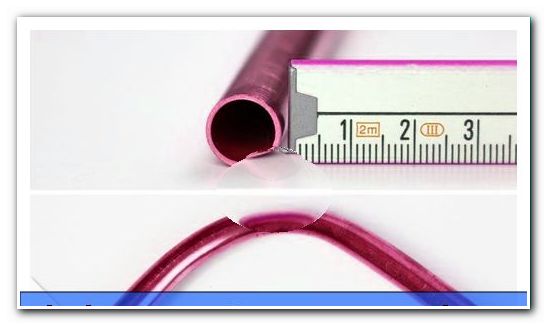

1. The outside diameter should be between six and 28 millimeters.

2. There are several risks when doing wrong:

- Hairline cracks can occur at the outer radius.

- The copper pipes can break.

- Wavy distortions can form on the inner radius.

3. Note the smallest possible bending radii. The radius of the neutral axis must be between 30 and 114 millimeters. With a spiral spring, the possible bending radius can be reduced.

Bend copper tube

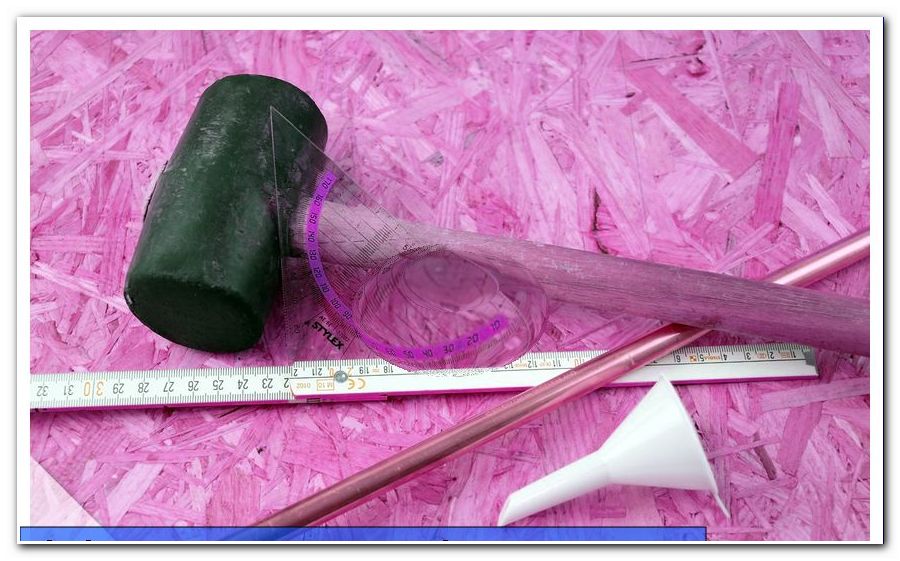

Bending by hand - you need these materials and tools when cold bending by hand:

- water

- sand

- duct tape

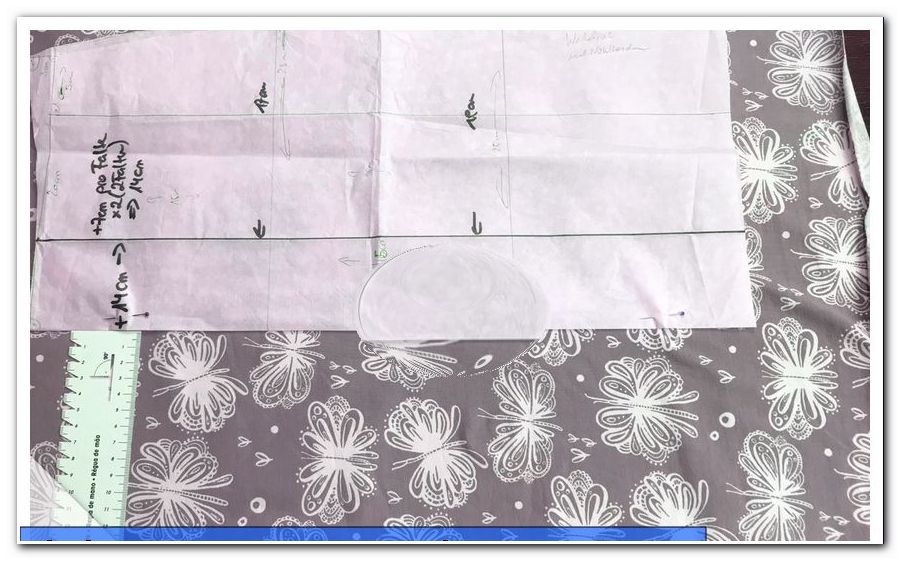

- pen

- ruler

- a bending resistance, such as a wheel rim, anvil or a rubber mallet

manual

Step 1:

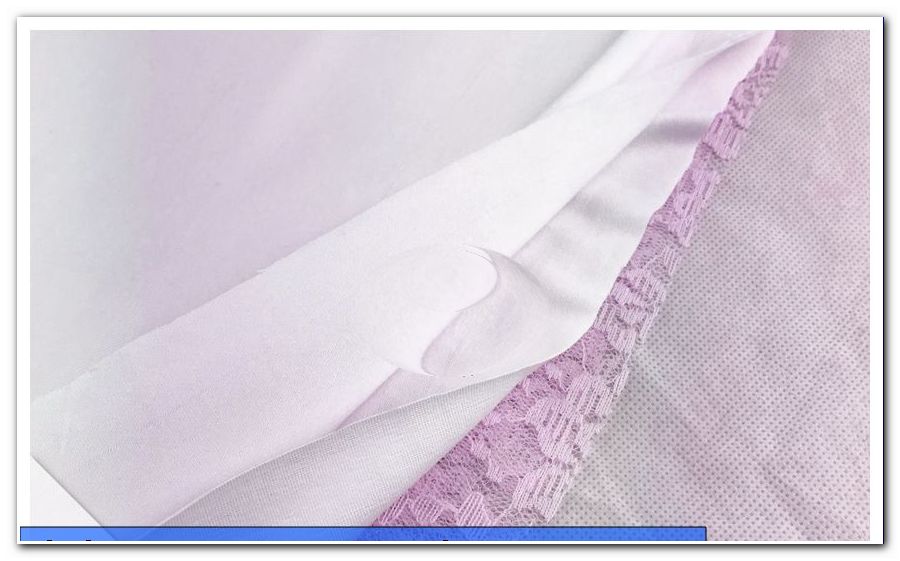

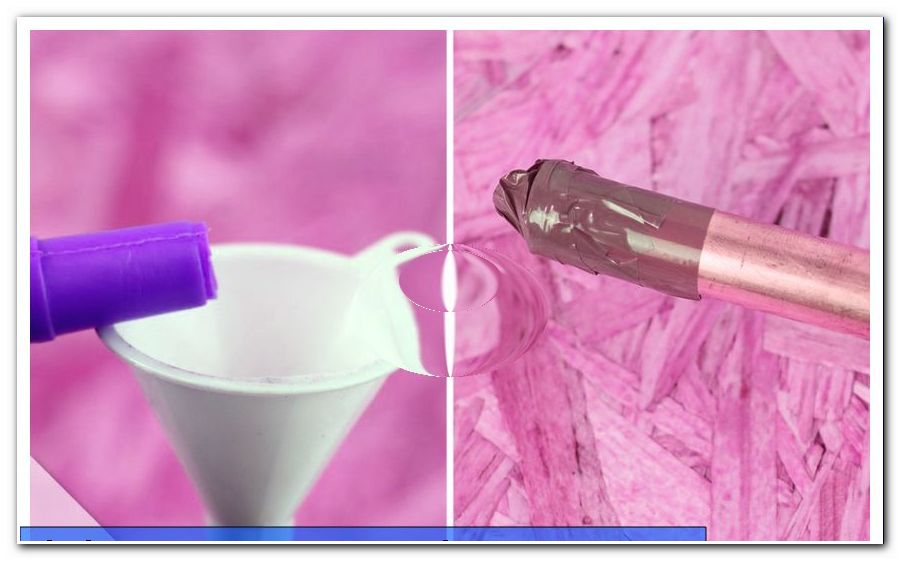

Close a pipe opening. Most copper tubes are already sold with two small caps. These can be used and simply closed with a finger of a rubber glove and some tape

Step 2:

Second, you need to fill the copper pipe with dry sand.

Tip: If you want to bend the copper tube by hand, then the outer diameter should not be more than 12 millimeters.

Step 3:

Now carefully pour water into the tube until the sand inside is wet.

Tip: Make sure that the sand in the pipe can not be rinsed out.

Step 4:

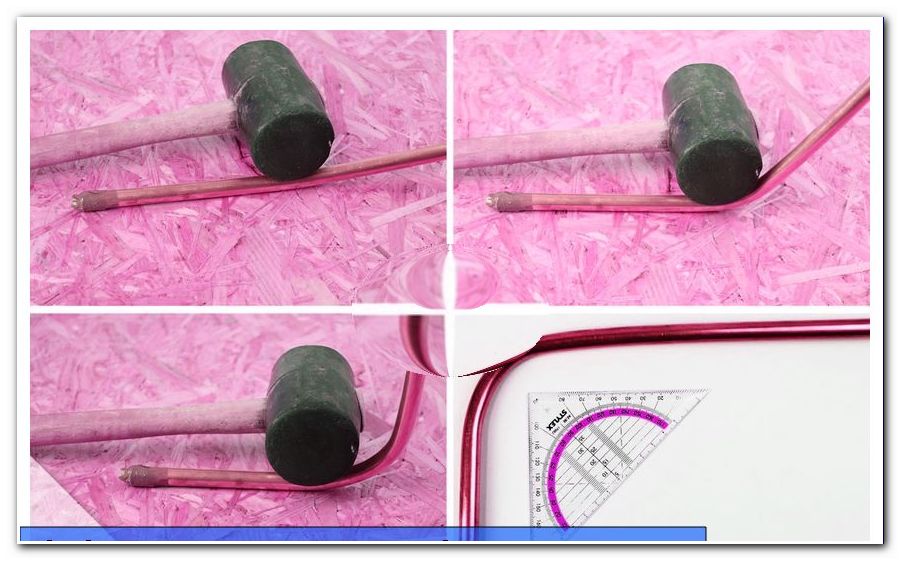

To start bending manually, you must now apply the object to be bent to the crest of the bending resistance. For example, use the edge of the anvil to give you firm resistance.

Tip: Make sure you have enough stability and a firm footing for the bending resistance.

Step 5:

Now push the bend into the pipe structure. Bend the tubes with a steady and strong pressure. Do not work too fast and check the current state in between with a protractor. You must not fall below the minimum bending radius.

Step 6:

After you have achieved the desired result, you must wash out the inside of the pipe well.

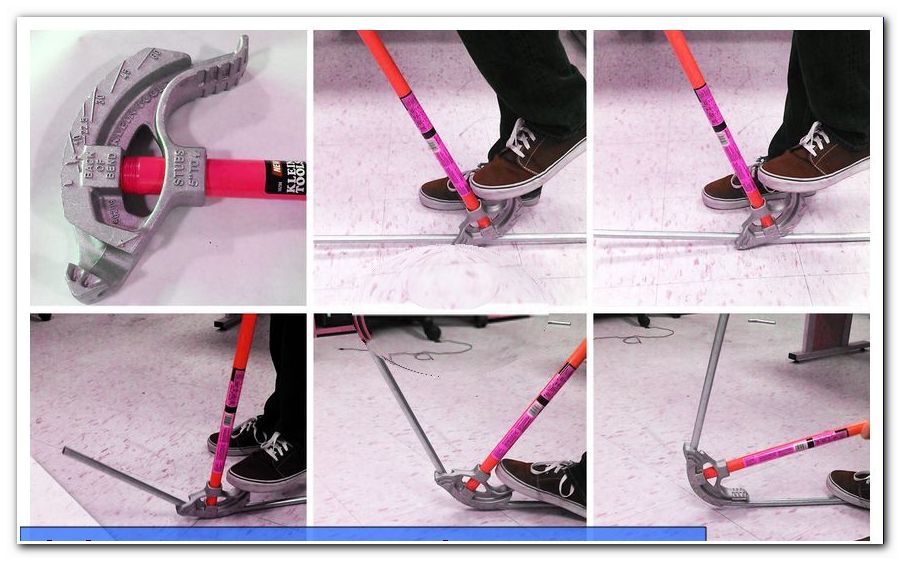

Cold bending with a bending machine

Step 1: For a bumper machine, you must put on the bending segment and the counterholds. For the drawing machine, set up the bending segment.

Step 2: Next, you need to set the appropriate pipe size.

Step 3: Now insert the copper tube. To do this, mark the pipe at the point which should be bent. The decisive factor is the vertex that is to be created by the bend.

Step 4: Make sure you have a tight fit. If necessary, you will need to tighten.

5th step: Now the bending process begins. The machine is equipped with a pressure handle, a lever or an operating rod. Electric bending machines must now be switched on and work automatically.

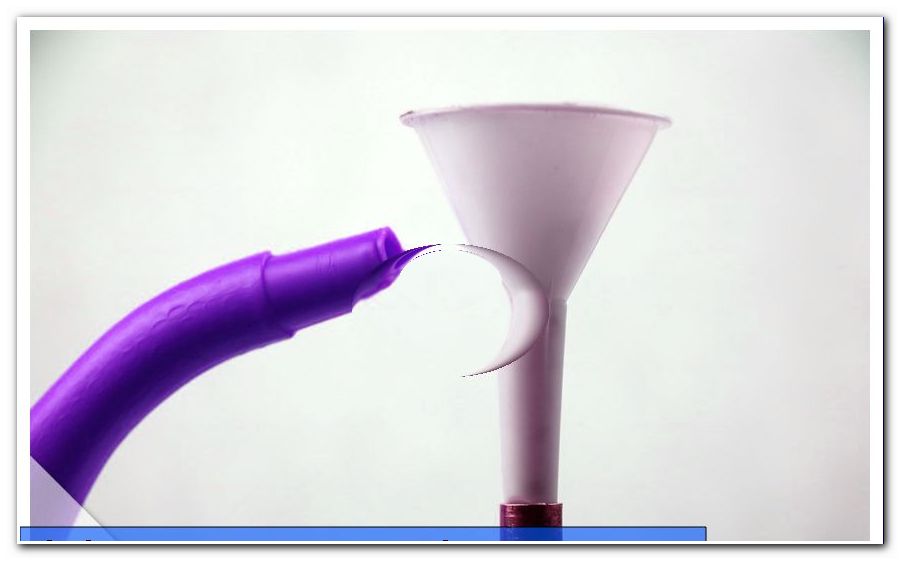

Turn copper tube with bending spring

The use of a spiral spring is another way you can deform a copper tube. It is a spiral spring without gaps. The inner diameter must be selected to match the tube to be bent. In general, the spring has a length of about 25 to 30 centimeters and is bent at one end. This allows the pipe to be inserted better. The permissible bending radius depends on the wire diameter of the spiral spring. The special feature of the spring is that particularly small bending radii are possible.

Step 1: Fill the tubes with the appropriate amount of sand, moisten them and then insert the tube into the spiral spring.

Tip: The more spring coils guide the copper pipe bend, the better the result.

Step 2: Place the copper tube at a suitable point and push the bend into the material. Pay attention to a uniform shape.

Which rules apply to cold bending ">

Turn a spiral

With a little practice and the appropriate tools, it is possible to bend spirals. In order for the individual turns of the spiral to be even, you need an object around which you can deform the tubes. For this example, steel pipes with a suitable diameter are suitable.

Attention: When selecting the tools you must pay attention to the outer diameter. The outer diameter of the auxiliary tube is later equal to the inner diameter of the resulting spiral.

Proceed as follows to form the spirals:

Step 1: Fill the pipe with sand and moisten it with enough water.

Step 2: Attach the copper tube to the auxiliary tube and bend it around the object. Pay attention to an even pressure.

3rd step: After completion of the spiral, wash the copper tubes well.

Tips for quick readers

- work with spiral spring

- Push copper tube in and bend

- start at a suitable point

- Bending resistance: wheel rim, anvil

- Bending by hand: pour in sand

- Wet the sand

- Insert bending machine

- Cold bending has advantages over Fittingen

- for a spiral, you need an auxiliary tube