Calcium silicate boards - All material info & prices

- Advantages and disadvantages

- Process calcium silicate boards

- costs

- Tips for quick readers

Calcium silicate boards are used when it comes to interior renovation. They require a high level of craftsmanship and are much more expensive than polystyrene panels as an insulating material. Their installation is, however, very quickly feasible. In addition, calcium silicate biologically is a completely harmless insulation material, which made it far superior to polystyrene plates. The main application for calcium silicate plates is mold control.

Good insulation, excellent breathing

Calcium silicate boards are mineral insulating materials made of silica, calcium oxide, water glass and cellulose. They are, similar to sand-lime bricks or aerated concrete, cured by hot steam. Calcium silicate boards have a sufficiently good insulation value of 0.053-0.07 W / mK in order to be recognized by the EnEV as an insulating material.

The greatest strength of the calcium silicate plates lies in their capillarity. These plates absorb extremely well a room and point humidity and give it back controlled. The result is always enough dry walls so that no mold can form on them. This makes the calcium silicate boards in the renovation of old buildings with listed facades so interesting.

Rescue for historic buildings

Calcium silicate boards are especially suitable for interior insulation due to their breathability. This makes them interesting for the renovation of buildings that have a protective facade. The measures initiated by the EnEV have a high energy saving effect. However, the usually applied to the outer wall thermal insulation composite system is usually made of plastered polystyrene plates. In the end, more and more houses look the same from the outside, which has already led to massive criticism. So that the cities and streets do not completely lose their face, now more emphasis is placed on interior insulation. This does not even apply exclusively to houses that are listed as historical monuments. Calcium silicate boards are ideal for a variety of reasons:

Advantages and disadvantages

... of sheets of calcium silicate

| + Simple processing (but which require knowledge and care) + Panels can be drilled through without heat loss + High pH, also contributes to resistance to mold + Rooms are heated directly, no need to warm up the exterior walls (warm wall effect) + Thus faster warming of the interiors + Baubiologisch uncritical + Excellent fire protection | - danger of "barrack climate" - Thermal conductivity is not optimal - No carrying capacity - expensive - Demanding in the coating - Loss of space through thick insulation boards |

Calcium silicate sheets can be cut well with a hand saw. For mounting a full-surface gluing with a toothed spatula is recommended. With a full-surface bonding an accumulation of moisture behind the plate is effectively avoided. Calcium silicate is one of the alkaline minerals. This makes it, in contrast to clay plaster, particularly resistant to mold . In the case of external insulation, a heating system first has to warm up the outside wall before it creates a uniform feel-good climate in the room. This is not required for interior insulation with calcium silicate panels. The interiors also heat up much faster than an external insulation. This makes interior insulation made of calcium silicate boards particularly suitable for rooms that are only used for a short time. The good landfillability is a huge advantage of calcium silicate. Here are massive problems and cost increases for owners of houses to be expected, which are insulated with polystyrene. Homeowners with an insulation made of calcium silicate can therefore look forward to the point of disposal costs.

In the section "fire protection", the sheets of calcium silicate are also clearly superior to polystyrene sheets. They are completely incombustible as a mineral insulating material. The topic of fire danger is becoming increasingly virulent in polystyrene panels. Calcium silicate boards are not only inflammable, they also reliably shield fires from the outside. Forest or street fires therefore have a much harder time jumping over the house with calcium silicate boards.

The "barrack climate" describes a phenomenon in which the air in the interior of buildings "stands" due to massive insulation. This occurs especially at high temperature differences from the inside out. The reason for this are missing heat buffers, where a certain exchange of air takes place. The plate itself is not sustainable. Dowels for wall cabinets and pictures must therefore be particularly long, since the calcium silicate board must be completely pierced. Calcium silicate has to accept lower insulation values than other insulating materials, which are also much cheaper. The price is still the biggest horse foot in the area-wide installation of calcium silicate boards. If, however, the disposal costs are added, the additional price for calcium silicate is somewhat better than for polystyrene panels.

The whole breathable effect of calcium silicate sheets can be negated again if a diffusion-proof paint (eg latex paint) is used. Calculated on the whole house, go through the use of thick insulating panels of calcium silicate some m² living space lost.

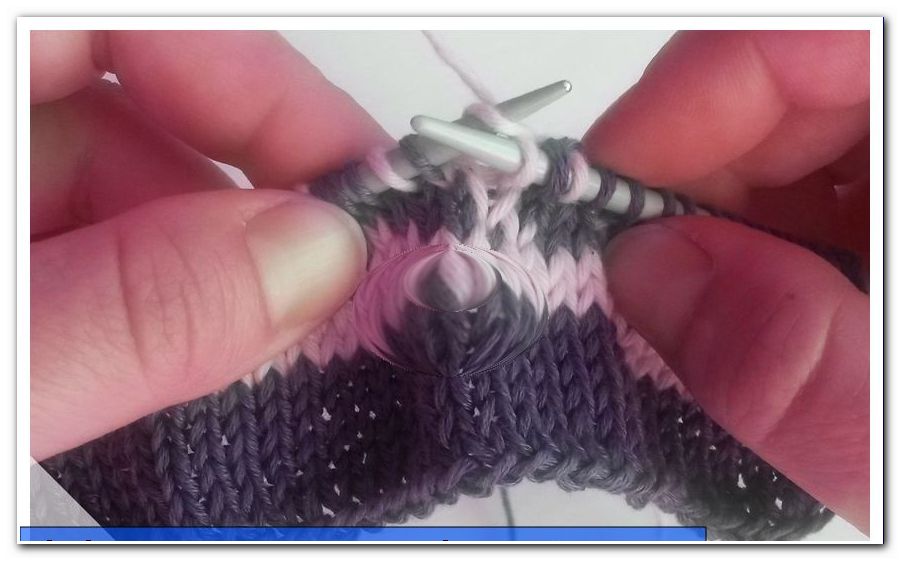

Process calcium silicate boards

The following tools are required for processing these insulation boards:

- Hacksaw (ca 12 Euro)

- Foxtail (about 15 euros)

- Drilling machine with stirring rod and drill bit (approx. 120 euros or 15 euros in rental)

- Mortar trough (ca 12 Euro)

- Scale (about 5 Euro)

- Smooth chip (about 8 Euro)

- Tooth spatula (approx. 18 Euro)

- Quast (about 5 Euro)

- Painting set (paint roller, brush, extension rod) (about 12 Euro)

- Rubber mallet (about 15 Euro)

The handling of glue and plaster is a very dirty matter. The wearing of appropriate clothing is therefore urgently indicated.

The calcium silicate board is also called "climate plate" . It ensures a balanced room humidity in the room. If it is used for mold control, existing mold must first be completely removed. Remove wallpaper and loose paint before coating. Spraying the shell wall before bonding with calcium silicate panels with a mold destroyer provides added security. An additional primer improves the adhesion of the adhesive.

The preparation of the plates must be done with millimeter accuracy. Socket holes can be made with a Core Drill Attachment with a standard drill. Here too, work is very precise. The plates are coated with a special primer with a puff. Then the calcium glue is mixed and applied generously with a smoothing tin. After application, the layer of adhesive with the toothed spatula receives a defined structure and thickness. Only now the plate with the primed side is pressed firmly against the wall. It must stick to the entire surface of the wall. Slight blows with a rubber mallet will easily hold the plate out. But you should definitely avoid corners, edges and especially gaps. With a friction board slight overhangs can still be re-smoothed. Finally, the wall is ready for plastering, puttying and painting.

costs

The price of calcium silicate boards depends on their dimensions and the purchase quantity. A standard size for these insulation boards is 1.00 m wide and 1.22 m long. Due to the low density, these large plates are also easy to process for a single worker.

Guide prices per m²

2, 5 cm thickness = 25, 50 EUR

3 cm thickness = 30, 50 EUR

4 cm thickness = 36, 90 EUR

5 cm thickness = 42, 50 EUR

6 cm thickness = 46, 90 EUR

7 cm thickness = 48, 00 EUR

8 cm thickness = 50, 00 EUR

For a normal room wall without windows so must be expected with 70-125 euros cost of insulation panels per meter length (room height 2.75 m). The thicker the insulation board chosen, the better it protects against the outside temperature. But much does not necessarily help in thermal insulation. Above a certain value, the increase in the insulating effect due to any further construction is only minimal. How big this value is depends on the existing building fabric. An exact calculation gives information about which heat protection is desired and reasonable. This is best done with the help of an energy consultant.

For window reveals there are extra thin and narrower calcium silicate plates. These leave a preassembled radiator still enough space to ensure the ideal air circulation. The almost 2 cm thick plates have a dimension of 0.5 mx 0.24 m and cost just under 7 euros each.

The adhesive for calcium silicate panels costs about 1.50 - 1.70 euros per kg. You can count on about 3-4 kg / m². The amount depends on the thickness of the plate and the unevenness of the substrate. Primer costs about 5 euros per liter. The primer is very rich. One liter is sufficient for about 3-10 m², depending on the absorbency of the substrate. Whether the climate plate is plastered or mirror-smoothed is a matter of taste of the user.

Breathable and excellently processable lime filler for climate plates costs approx. 1.60 per kg. For a 2-millimeter thick layer, approx. 3 kg of filler is required per m². Climate protection is apparently cheaper with 1.30 euros per kg. For a correct plaster, however, a thickness of 10 millimeters is required, which corresponds to about 10 kg ready-mixed mortar per m². This solution is therefore much more expensive than lime filler. With a reinforcement fabric for approx. 2.50 Euro per m², cracking is prevented effectively when plastering or filling.

Finally, there is still color on the wall. It is strongly discouraged to wallpaper a wall of calcium silicate boards. Also latex paints are unsuitable for climate plates. One liter of paint for calcium silicate panels costs about 5.60 euros. It is enough for about 6.5 m².

In summary, the following costs result for a m² wall that has been clad with an air-conditioning panel:

- Climate plate: 25, 50- 50 Euro

- Primer: 0, 5 Euro

- Adhesive: 5 euros

- Spatula: 5 Euro

- (Plaster: 12 euros)

- Reinforcing fabric: 2.50 euros

- Color: 1 Euro

- Together: 43.50 - 76 euros, depending on the thickness of the climate plate and type of paneling

However, one must remember: The maximum thickness of 8 cm is rarely necessary and really useful. For normal applications, climate panels with a thickness of 3-8 cm are used. In any case, the use of climate plates has done the maximum possible to prevent mold infestations. However, this only applies to mildew, which assumes a bad indoor climate and thermal bridges. In the case of heavily moistened walls due to a damaged exterior plaster or a damaged water pipe, even the best climate plate is powerless.

Calcium silicate boards are ideal for refurbishing cellars. From former musty-damp basement vaults can be created with the help of these plates a fully usable space. The increase in housing value and thus also the increase in value of the house should be considered in the initially high costs of this renovation measure. However, this requires absolutely dry outer walls.

Tips for quick readers

- Calculate thickness of plate with energy consultant

- Always prime the boards

- Always coat plates with diffusion permeability

- Cleaning cloth prevents cracks

- Renovated cellars increase the value of the house