Renovate Wooden Staircase - DIY Guide and Cost Example

- Planning and preparation

- material

- Renovate wooden staircase in 6 steps

- 1. grinding

- 2. Mending

- 3. Railing

- 4. Fix creaking

- 5. pickling

- 6. Coat stairs

- Price and costs

- Tips for quick readers

When the old wooden staircase just creaks, has a lot of quirks and generally looks a bit shabby and worn, it's time for a makeover. How this can be accomplished by itself, what you need for it, and how it works, reveals this post. In addition, which other possibilities of the renovation there are, and what all this costs.

Wooden stairs are components that have to endure a lot. This not only includes the wear and tear of stepping on the steps. Even the supporting structure of a staircase must withstand a lot of weight. In particular, when stairs are older, a renovation is often inevitable. But you can either lend a hand, and restore the original stairs, but are also possible disguises. The workload is lower, but the costs are slightly higher. Of course, renewing a staircase is also an option. A detailed comparison of the costs of all these measures can be found at the end of this article.

Planning and preparation

Determine the renovation effort

Minor damage to stairs or the stair stringers (with a stringers staircase) you can easily repair yourself. However, if the stairs are creaking, warped, or making a crackling noise, check the load-bearing capacity of the staircase and inspect the wooden staircase for any visible damage to the support structure.

If the load capacity of a staircase is no longer given, this can be very dangerous. If in doubt, you should definitely consult a specialist here, especially with antique wooden staircases, who will examine the staircase for its carrying capacity. If there are concerns, the stairs must be renewed.

material

Once the (very important) point has been clarified, and the staircase is safely stable, it is possible to set the scope of the necessary work. Watch out for:

- visible cracks

- deep damage or quirks

- heavily worn step edges

- Degree of pollution of the stairs

- Damage to the railing, condition of the railing

- Creaking noise at the steps

You need this:

- Sandpaper in different grain sizes

- Grinder (orbital sander, triangular sander for the edges)

- Wood filler or self-made wood balance compound

- possibly acrylic

- possibly screws for additional fastening

- ev. primer

- possibly stain

- Wood varnish or wood oil or wood wax

- brush

- paint roller

Tip: If you do not like the original color of your staircase, and you would like the stairs in a different wood color, you can easily change it by pickling during the renovation. Any commercial stain is suitable for this.

Renovate wooden staircase in 6 steps

1. grinding

At the beginning of the work, the wooden staircase must be ground very thoroughly. For example, dirt that has penetrated under the wooden surface is removed, and the damaged wooden surface is removed. All old coverings and layers of paint must be completely removed.

Notes on grinding

The best way to work for the larger surfaces is with an orbital sander, and in the corners and edges with a triangular grinder. The grinding can still be tedious. This can be very tedious and time-consuming, especially when removing well-adhering paint layers. Remedy can also provide hot air blower - this will soften the paint, and can be easily scraped off with a spatula in the semi-liquid state. However, the method should be used with care, since the high temperatures could also scorch the wood.

To remove all dirt and deposits, you should always perform at least three sanding cycles. Basically, you start with sandpaper in 80 grit, then the next sanding with 120 grit the so-called intermediate sanding is applied. The final cut usually takes place with 180 grit. A very fine and smooth surface can be achieved by sanding afterwards with 240 grit.

Tip: Very easy to get a staircase like new, if you use the so-called dry ice blasting. Dry ice blasting is also possible as a mobile application, various specialist companies offer an in-house use of mobile devices.

Dry ice blasting works with carbon snow at a temperature of -80 ° C. The impacting ice particles cause the soiled surface to embrittle and splinter, leaving the clean, unweathered, raw and very clean wood behind.

Since the blasting agent used quasi "in air dissolves" (it forms only carbon dioxide) remains no blasting agent, which would have to be removed later (only a very small amount of dirt particles). The process is very gentle, does not damage the wood and does not remove anything from the surface. It is also used successfully in the protection of monuments as a mobile application. This saves a lot of effort, because then only a fine grinding must be performed.

2. Mending

If after sanding various coolings and depressions are left over, you can repair these places with wood spatula (wood balance mass). To do this, carefully press the wood filler into the recess with a small spatula until the surface is level. Then allow to dry according to manufacturer's instructions. Make sure that you hit the wood color of your staircase as exactly as possible. After curing, carefully sand the area again to match the surface.

Tip: If you can not find the right wood shade, or if you want a really perfect repair, you can resort to an old carpenter trick: Mix some of the fine sanding dust with a small amount of wood glue until a tough paste is formed. The paste should have exactly the wood color, otherwise add more sanding dust. Use as wood filler.

3. Railing

Just round or turned railings are very difficult to grind. You will probably need to do a lot of manual work here, or you will need to use appropriate renovation tools with very small attachments.

The same rules apply to sanding the railing as for sanding the steps and stair stringers (see point 1). Exception: If you want to repaint an already painted railing, you can use acrylic paint and then only need a medium to fine bevel.

Tip: Acrylic lacquer is one of the most suitable lacquers for the interior. It forms very well adhering surfaces that are completely UV-resistant and even elastic. Acrylic paint is water-based, solvent-free, virtually odor-free and also resistant to saliva and sweat. (important for very young children in the household). You can use it as primer, intermediate coat and top coat (so-called "one-pot" system, only one coat is needed) and very easy to dilute with water.

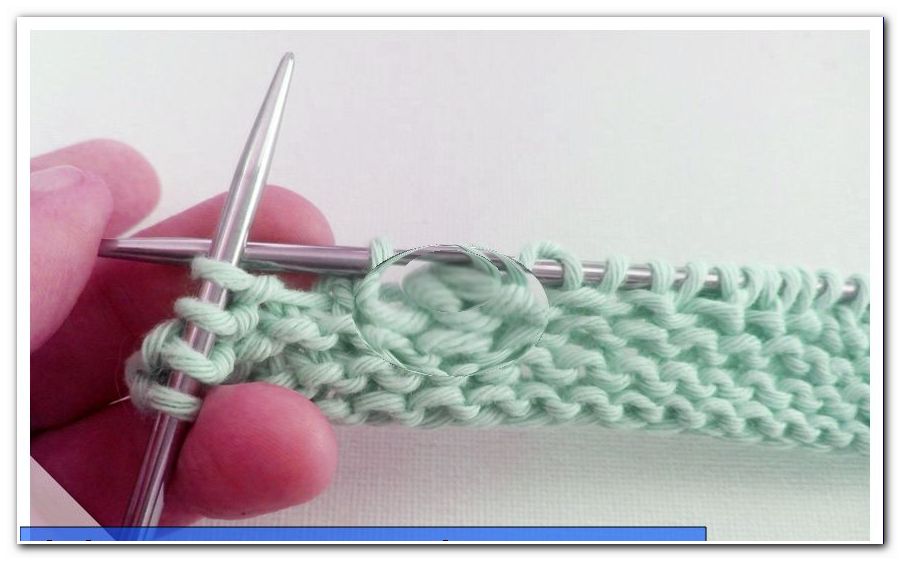

4. Fix creaking

In many cases you can easily fix creaking stairs yourself. To find out what you need to do, first pay attention to where the creaking sound comes from:

- from the front of a tread (very common, tread wear due to step treading)

- in the area of the stair string (too much play in the stage pockets)

- from the area between step and riser (vertical part, here too much play in the joint)

The fix is then relatively simple. Fold the corresponding gap (preferably with two wedged wedges) until the gap widens. Then the gap can be easily filled with acrylic from a spray gun. The creaking should be corrected after hardening of the viscoplastic acrylic.

Just put a wedge into the joint on the side pockets and cut it off flush. Alternatively, you can also use acrylic, but this is not quite as effective as the tight wedging of the step in the cheek with too much play in the cheek pouches.

Tip: The tight screwing of parts that have some play, often does not bring the desired success, and is also usually much more complex and laborious.

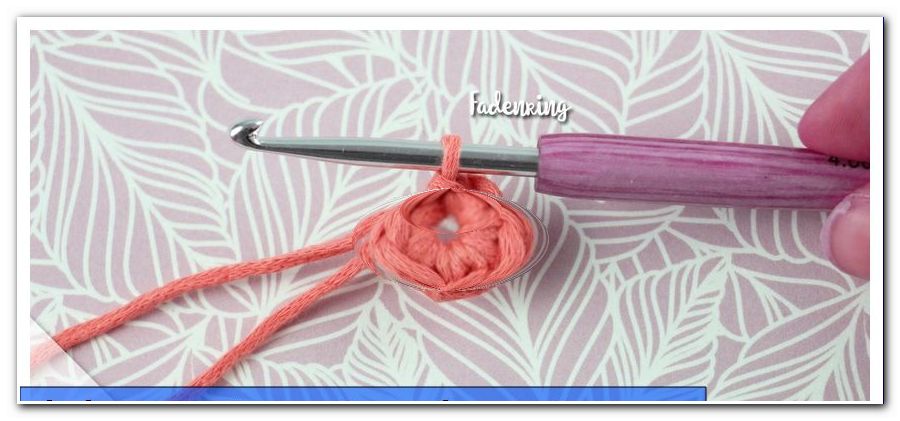

5. pickling

Of course, this step can be omitted if you are happy and satisfied with the color of your staircase. Otherwise, you can easily use a suitable commercial stain on the ground wood. If your staircase is made of solid wood, it is best to use a special stain for this type of wood.

Tip: What you should think about is the grain of the wood. Pickling retains the grain, but it does not always match the chosen wood color. In some circumstances, this may look rather unattractive in the case of unfortunate combinations (for example, oak wood color on pine wood). Ask for security rather in the retail trade again.

6. Coat stairs

For the surface coating of the stairs, there are various options available:

- clearcoat

- glaze

- Oil

- hard wax

- possibly also wooden soap (for very rustic stairs)

The most natural way of treating wood is definitely oiling. Oiled wood is highly resistant as the oil penetrates several millimeters deep into the wood, protecting itself from the wood fibers before hardening and providing stable protection. The best and most natural oil for all woods is linseed oil. It takes a long time to dry (up to 10 days and more). Boiled linseed oil (so-called linseed oil varnish) dries much faster and provides similar protection. The disadvantage of oiling, however, is that oiling must be carried out regularly (usually once a year, and more frequently at heavily used areas).

Hard wax does not penetrate into the wood, but remains only on the wood surface, from where it is relatively quickly rubbed off. For such heavily used wooden components as stairs, it is a rather unsuitable choice to protect the wood really well.

The best protection is certainly provided by clearcoats and glazes. They are also highly recommended as protection if the wood has been previously stained. Clear lacquer, just like glazes, can simply be painted with the roller. For the corners you can use a suitable brush.

A special way to protect very rustic and above all antique wooden stairs is wooden soap. It not only serves as a cleaning and care agent, but can also be used as a wood preservative (so-called "Swedish method). For this she is applied in high concentration on the stairs until she moves in. This is only necessary once, then it can be wiped off in a lesser concentration once a month. Incidentally, old peasant women know that soap-soaked wooden floors become especially beautiful and shiny when you wipe them with some milk after cleaning them.

Tip: Since the painting and glazing in the corners and on the railing is not so easy, and often not completely clean, you can consider the purchase of a spray system. Spray systems for paints, varnishes and dispersions ensure a very thin and very uniform application in all places, even in corners and at the edges. In addition, you can use the system (if appropriate) well later to paint the walls well. The purchase may therefore be worthwhile.

Heavily worn steps

If steps are already severely worn, and the edges already rounded off by walking, this can often not be repaired by sanding alone. In these cases, only either a so-called "doubling" of the stairs remains. - or a complete renewal (replacement) of the stairs. Step edge profiles would still be a possibility if only the edges are worn, but this rarely looks really nice on wooden stairs.

Dressing stairs

An old wooden staircase can be completely covered. For this purpose, so-called renovation systems are made to measure, which are then mounted on the stairs and on the stair string. They can consist of different materials. In view of the prices for such a renovation, however, the question arises, if one does not completely renew a staircase. In the long term, this is often the cheaper - and usually visually appealing - alternative.

Price and costs

Without a doubt you are of course the cheapest to renovate your own staircase, and get along with sanding, mending and repainting. Depending on which tools you purchase or have available, you often get by with very little money. However, a considerable amount of strenuous work beckons for that. Dry ice blasting, for example, can make your life much easier, especially on very old and severely damaged stairs.

Sharing costs with craft companies

In some cases, you have the option of agreeing with a craft company to do some work on your own and have the rest done by the professionals. This may be particularly worthwhile if repair or replacement of individual stair parts are necessary. Often this represents a financially favorable compromise.

Dress up stairs

For straight staircases with between 13 and 15 steps you have to expect a cladding from the professional already quite 2, 000 euros for the stairs and possibly even an additional 1, 000 euros for the stair string. Mount yourself is a bit cheaper, but not easy. Especially for the tailor-made cutting you need a lot of skill.

New stairs as desired

We once looked at what a straight wooden staircase costs the specialist company. Our staircase should be 100 cm wide, have 11 steps and have a step width of 28 cm.

First, the cost of dismantling the old staircase: Without disposal, the costs are around 50 - 60 €, with disposal by the company at around 80 - 100 € for our old staircase. If the disassembly is complicated and only handsets can be used, the price can be up to twice as high.

Then we have the stairs rebuilt.

Primed and sealed costs our staircase including installation then between 3, 200 euros and 4, 100 euros (net price). The stair railing must then be paid separately. High-quality types of wood, such as the tropical and very hard Kambala wood, but also oak or walnut, drive the price then significantly in the amount, up to 6, 000 euros are then possible for our stairs.

Even a steel staircase as a replacement would cost about 4, 500 euros, stainless steel about 5, 500 euros. (All prices net). The steps can be made of wood, glass or plastic. Natural stone is usually possible.

The labor costs account for only about 800 euros (wooden staircase) or about 600 euros (metal staircase). The rest are material costs.

Kit staircases

Finished stairs, on the other hand, are much cheaper, the installation can often even be carried out quite easily yourself (attention: liability!). A very space-saving spiral staircase (only for building law not necessary stairs) you often get for 600 - 800 euros in the trade. Higher-quality versions can then quite with 1, 800 - 3, 000 euros to book. For a cost-effective replacement of a wooden staircase if it is necessary, these stair kits are therefore quite an interesting alternative.

Tips for quick readers

- check the carrying capacity of the staircase before renovations (if necessary by a specialist)

- no longer sustainable stairs must be completely renewed

- basic renovation: sanding - repairing - fixing - (staining) - recoating

- cleaning with dry ice blasting can save a lot of sanding

- Dressing up the stairs is often costly and difficult

- Prefabricated stairs as kits offer a good alternative if the stairs have to be replaced