Screed information - prices of screed types and all costs

- Screeds and their applications

- Screeds according to material

- Screed types after installation

- Additional costs for screeds

Screed is the name for the top layer of an irregular, rough or unsuitable surface. The primary task of the screed is to produce a smooth and even surface on which the decorative or technical flooring can then be applied. In addition to this function, Estrich has many other tasks.

Screed is bought only once

There is only one case in which it may be useful to replace an existing screed. Only when retrofitting a floor heating, which is also operated with water, a demolition of an existing screed layer may be necessary. Otherwise, screed is the same as any other building material: those who buy cheaply buy twice. The guide prices listed here for the most common types of screed can be taken as a guide. Essentially cheaper screed you buy in principle with compromises in quality. So if you want to avoid unwanted side effects such as cracking, bursting or premature erosion, should pay attention to brand quality.

Screeds and their applications

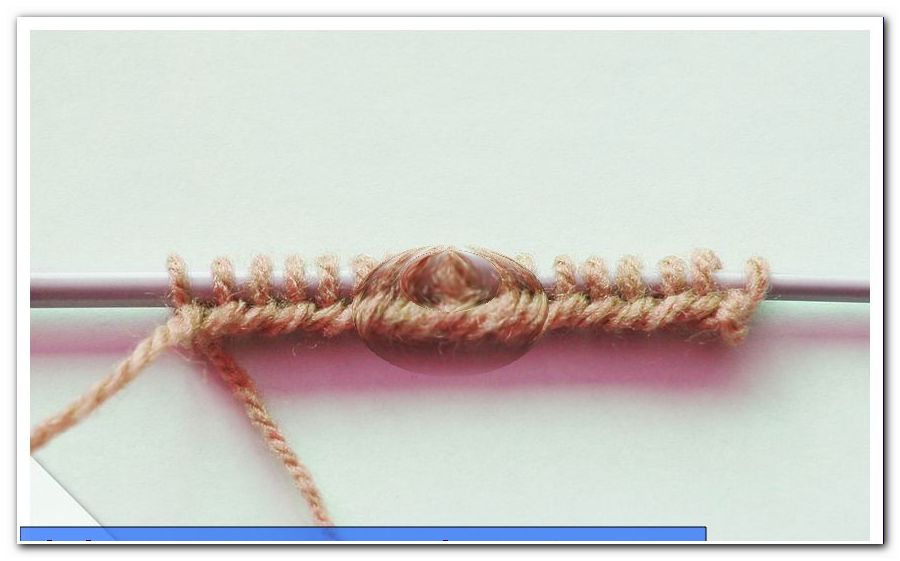

There are two ways of distinguishing each type of screed from one another: material and method of installation. The choice of material limits the choice of installation. Some types of screed can be installed by the brave do-it-yourselfers themselves. For others, he depends on a specialist company. In addition to the sack price, an example quantity is given here by way of example. The required quantities are designed for a typical living space of 20m² . The layer height varies according to used screed and other factors. Basically, each screed covering requires a reinforcement mat to prevent cracking during setting and use. At 2 euros per square meter, however, the costs for a reinforcing mat are negligible.

Screeds according to material

Cement screed (CT):

The cement screed is a universal screed that can be used both inside and outside. Basically, cement screed is just a very fine mortar that is mixed with lime, cement and sand. You can make cement screed yourself. Its installation, however, is demanding and requires a lot of prior knowledge. Cement screed is usually installed in damp earth. The advantage of cement screed is its universal suitability.

The prices for cement screed are very variable. With a brand manufacturer like Dykerhoff, Knauf or PCI you can always expect the best quality. The setting time, however, is decisive for the price fluctuation. A simple 25 kg bag of cement screed is available from just 2.50 euros. A fast-binding screed, however, can easily cost ten times as much.

Example calculation (20 m²)

A 25 kg bag of cement screed gives 15 liters of built-in volume. Now it depends on the installed layer height:

- 3 cm (normal height on smooth concrete) = 0.5 m² per bag = 40 bags at 2.50 euros = 100 euros

- 5 cm (recommended height for very irregular ground) = 0, 3 m² per bag = 60 bags for 2, 50 Euro = 150 Euro

- 7.5 cm (prescribed height for insulation layers / underfloor heating) = 0.2 m² per bag = 100 bags at 2.50 = 250 euros

Calcium sulfate screed (CE):

Calcium sulphate screed is gypsum-based screed. This screed is typically used as a liquid screed. The high proportion of gypsum makes it unsuitable for outdoor areas and humid environments. Gypsum-based building materials tend to soak and can then form fouling. Inside, however, it is standard in use and is particularly suitable for underfloor heating. But he can not be used in the bathroom.

Example calculation (20 m²)

A 40 kg sack of calcium sulfate screed gives about 22 liters of built-in volume. For the room of 20 m² this means:

- 2.5 cm (nominal height as a simple cover layer) = 0.8 m² per bag = 25 bags at about 8 euros = 200 euros

- 3.5 cm (nominal height for screeds with underfloor heating) = 0.62 m² per bag = 33 bags at 8 euros = 264 euros

Mastic asphalt (AS)

The mastic asphalt screed is not very widely used in interior design. Neatly processed and polished and polished, the dark, elastic and heat-insulating mastic asphalt screed can be very appealing. Its processing is demanding and should only be carried out by specialized companies. With 25 to 30 euros per square meter, he is not cheap. For our example room, 600 euros would only be due to the client for material costs for the screed.

Magnesia screed (MA)

Magnesia screed is a pronounced special screed, which is hardly accessible to private users. It combines many positive qualities such as elasticity, thermal insulation, electrical conductivity and much more. However, magnesia screed is difficult to install and must be professionally sealed because of its high hygroscopic properties. For this purpose, synthetic resins are used. Also magnesia scent reacts aggressively to metals.

Since magnesia screed is laid only by professional companies, the prices are difficult to determine. Basically you can expect at least 100 euros per m² .

Synthetic resin screed (SR)

Synthetic resin screeds are widely used in laboratories, public buildings and in industry. They combine many positive properties such as impact strength, insulation, abrasion resistance, resistance to moisture and chemicals. Synthetic resin screeds, like the magnesia screed, are only processed by specialist companies . The coordination of all components requires a high level of expertise. The installation and curing processes are also subject to strict work steps, which must be strictly adhered to. Above all, the ventilation during curing must be guaranteed, otherwise there is a risk of damage to health and even the danger of explosion. This makes resin screeds for home improvement and private individuals mostly uninteresting. The resin screed itself is already one of the most expensive types of screed that you can buy.

However, there are thin-film synthetic resins that can be used as a topcoat on existing screed. These applications allow particularly spectacular textures in which flakes and chips are incorporated. They are applied only in a thickness of 2-5 millimeters and cost about 170 euros for a 30 kilogram bucket. This is enough for approx. 8 m² and is ready for installation mixed. A professional craft company calculates for the synthetic resin coating of screed about 40 euros per square meter.

Screed types after installation

topping

The composite screed is a simple, balancing cover layer that is applied to a shell subfloor. Composite screeds are independent of the screed material. They are suitable wherever there are no high demands on the screed. These are, for example, screeds in garages and basements. Depending on the installation site, care must be taken as to whether the screed must be pressure-resistant, weatherproof or resistant to moisture.

With composite screed, there are hardly any additional costs. In order to avoid cracking and to create a separating layer to the outer wall, we recommend a narrow insulating strip, which is attached to the inner wall all around. A 30 meter roll of joint tape costs about 8-12 euros.

A professional craft company calculates about 25 euros per square meter of composite screed.

Floating screed

Floating screed is standard for living rooms without underfloor heating. It consists of an insulating layer of hard foam and a top layer of screed. Floating screed is mandatory for multi-family houses, otherwise the normal use of the apartment causes considerable noise pollution for all other residents.

For the professional installation of floating screed, only suitable materials are permitted. Above all, the insulation boards must have exactly defined compressive strengths, otherwise you have at the latest when setting up a wall unit depressed floor.

Impact sound insulation costs different amounts per square meter, depending on the thickness:

- 20 mm thickness (minimum): 1.50 to 3 euros

- 30 mm thickness: 2.50 to 3.50 euros

- 40 mm thickness: 3.00 Euro to 4.50 Euro

- 50 mm thickness: 3.80 to 6 euros

The thicker the impact sound insulation, the better its insulation performance. Particularly thick impact sound insulation also has a high heat-insulating effect. By investing in a thicker impact sound insulation, a big saving effect in heating costs can be achieved so quickly.

In addition, the impact sound insulation must be separated from the screed with an insulating layer covering. This prevents liquid screed from flowing through gaps in the impact sound insulation and creates a sound bridge to the floor. Smallest contacts between the screed and the raw construction floor are sufficient to destroy the entire effect of the floating screed. For the insulation layer cover is sufficient simple PE film . The prices vary greatly depending on the container size. It is advisable to buy a larger role, you can never have enough film on a construction project. A roll of 100 m² costs about 90 euros . Finally, reinforcement mats (2 euros per square meter) and edge strips or joint tape are required.

A professional craft company calculates for the installation of floating screed about 40 euros per square meter.

heating screed

The screed - ie the screed with integrated underfloor heating - is the supreme discipline when laying screed. Handyman without the necessary expertise take a big risk if they try themselves on this work.

This procedure is only necessary if a floor heating system with water hoses is to be installed. Electric underfloor heating systems are very thin and can be laid directly under laminate, parquet or a tiled surface.

A heating screed consists of pressure-resistant insulation board, possibly additional impact sound insulation, retaining plate for the piping, the heating pipes or hoses, PE film as a vapor barrier and finally the screed itself. Construction and type can vary, but the materials themselves do not change.

The prices for the pressure-resistant insulation board are the same as for footfall sound insulation at around 5 euros per square meter. This should not be waived, otherwise the expensive heating energy escapes unused down. As holding plates for the hose lines of underfloor heating systems come into consideration. Tacker boards are special boards on which the hose lines are attached by cable ties. For this purpose, a special tool, the stapler, used. It costs 100-300 euros, but can be rented in the tool rental but for about 15 euros a day.

A tacker plate costs about 3.50 euros per square meter. Knob tube carrier plates are competing systems that do not require stapling. They cost about 6.50 euros per square meter. The tacker plate offers an additional insulation performance.

The PET pipe for underfloor heating costs about 0.5 euros per meter. The required quantity depends on the room geometry. The PET pipe has at least a height of 16 millimeters, which requires a height of screed of 35 to 50 millimeters. Finally, in the floor heating still vapor barrier and mounting material are added, which are to be calculated with about 20-50 euros per room.

Additional costs for screeds

But also often advertised for DIY home improvement floor screeds are far from being as simple in the processing, as is generally claimed. Above all, the mixing ratios must be exactly right, otherwise the screed becomes pulpy and the result irregular. For liquid screed, the best solution is calcium sulfate screed.

With a little courage and skill, a home improvement is not overwhelmed with a dry earth or dry screed. With appropriate prior knowledge and conscientious execution is obtained in dry and humid installation controllable results and is protected from nasty surprises. Although these processes take longer, they take much less time to dry.

In addition to the pure screed, there are additional costs for installation. How high these are depends on the type of installation.

For the installation of screeds you need

- 1 mortar tub about 15 euros

- 1 set of work clothes (screed work is VERY dirty!)

- 1 wheelbarrow (about 50 Euro)

- 2-3 buckets (about 5 Euro)

- Only for floating screed: 1 drill with whisk about 150 euros (rental prices from 25 euros per day)

Additionally with dry / earth-moist installation:

Additionally with dry / earth-moist installation:

- 1 set knee pads about 15 euros

- 1 goggles about 5 euros

- 1 trowel about 10 euros

- 1 screed-smoothing chip about 10 euros

- 1 float

- 1 aluminum rail about 30 euros

- 1 long spirit level (2 meters) about 30 euros

Subsequent costs screed

Flooring screed usually needs to be sanded after installation. Special concrete and screed grinding machines are used for this purpose. Handset costs from about 200 euros. Professional machines can be rented from 100 euros per day. Used Screed Grinders are available from about 350 euros in operational condition.

Screed must mature sufficiently and dry. It is advisable to complete a room with fresh screed and secure against entry.

Tips for quick readers:

- Watch a few videos and instructions for dry screed. The installation takes a little longer, but is more controllable. In addition, the drying times are slightly shorter with earth-dampened screed and you have much less vapor diffusion in the house.

- Expensive experiments with mastic asphalt or magnesia should be well considered. Optical effects can also be achieved with the right flooring. On the other hand, upgrading a damaged floor with a thin synthetic resin layer is an inexpensive and very interesting option.

- When installing underfloor heating, conscientiousness is the top priority. Overlooked leaks, damaged pipes and mis-fitting sleeves can only be repaired with great effort. Also check whether the ceiling height of a room makes it possible to install underfloor heating with hose lines. Below 2.20 meters, the feeling of space becomes uncomfortable. In this case, consider electric underfloor heating as an alternative.