Epoxy coating explained and cost overview

- Overview of the resins

- Processing of epoxy resin

- Tips for quick readers

Epoxy resin is the drug of choice when it comes to producing durable and waterproof surfaces. It is ideal for sealing porous and organic materials. In addition, epoxy resin can be used in conjunction with glass fiber mats for producing freeforms of all kinds. In fact, this material, also called "two-component adhesive", plays a decisive role in prototype construction and in wind power. Learn in this guide what to look for when processing epoxy resin and what costs are incurred.

Durable material with good-natured properties

Epoxy resin, 2-component resins or two-component adhesives have been used both privately and universally for many years. It consists of the two components "resin" and "hardener". Both materials are relatively viscous masses, which become more fluid under heat. Unmixed, they stay in their usual liquid consistency for a long time. But once they are mixed together, a chemical reaction begins. This creates a solid mass that does not deform under temperature and mechanical load.

Demanding in processing and disposal

As practical as the properties of epoxy resin are, this material is very demanding in terms of processing and disposal. Epoxy resin can deliver great results at the intended location. Until then, however, much can be done wrong. This is especially true for its preparation: The respective mixing ratio must be maintained exactly, otherwise the material gets undesirable properties. This can result from a sticky surface to cloudiness and cracking.

It is also important when dealing with epoxy resin and occupational safety. When mixed, epoxy consistently sticks everything it comes in contact with. When mixing and applying epoxy resin, it is essential to wear at least eye protection. In case of contact with the eyes, the eye must be rinsed under clear water for at least 15 minutes and then a doctor should be consulted! Also skin contact should be avoided. That is why the wearing of body suits when handling epoxy resin is mandatory. These are, for example, paper protective suits. On fast rotating drills, you should avoid using epoxy resin. The danger is otherwise too great that the material spills or splashes around.

Overview of the resins

Epoxy resin is not the same epoxy resin. The retailers offer a selection of resins, with which the appropriate funds are available for the respective project. In addition to the epoxy resins, we also list their related polyester resins here.

As with many building materials, the price depends on the container size. A one-kilogram can is particularly uneconomical. Starting at 5 kilograms, the price already halves for most products and only slightly decreases from this mark. Therefore, always try to use 5 kilograms or more. Join with friends for a team for collaborative projects. So you can save a lot of money.

The trade offers epoxy resin in combination package of resin and hardener. You can also buy resins and hardeners separately from each other. However, we recommend that you always choose the combination packages. This gives you the confidence that you have always bought the best matching products.

This overview should give you an orientation for the prices. We have oriented ourselves to the products of the famous brand "Resinpal". The main difference between polyester resin and epoxy resin is the amount of hardener needed. With polyester resin only a few grams are needed. Epoxy resin is up to 25% of the mass of hardener. This must be taken into account when calculating the required quantities.

Polyester resin Resinpal 1705 including hardener

This is a standard resin that can be used well for model making and product manufacturing. It cures without tack and provides a hard, shiny surface.

- One kilogram of polyester resin Resinpal 1705 including hardener cost about 10 euros

- Five kilograms of polyester resin Resinpal 1705 including hardener cost about 30 euros. That corresponds to a price per kilo of 6 euros

- Fifty kilograms of polyester resin Resinpal 1705 including hardener cost about 240 euros. This corresponds to a price per kilo of 4.80

Polyester resin Resinpal 1714 including hardener

This cobalt-accelerated polyester resin is suitable for end products that are subject to high mechanical and thermal stresses. It is well applicable for both private and industrial processing.

- One kilogram of polyester resin Resinpal 1714 including hardener cost about 10.50 euros

- Five kilograms of polyester Resinpal 1714 including hardener cost about 31 euros. That is equivalent to a kilo price of about 6 euros

- Fifty kilograms of polyester resin Resinpal 1714 including hardener cost about 267 euros. This corresponds to a price per kilo of 5.30 euros

Polyester resin Resinpal 1719 including hardener

Special emphasis was placed on tacky curing in this resin. This makes it particularly well suited for repair work of GRP components. In addition, it is needed for waterproof applications. An individual pond construction can be implemented particularly well with this 2K resin

- One kilogram of polyester resin Resinpal 1719 including hardener cost about 10.50 Euro.

- Five kilograms of polyester resin Resinpal 1719 including hardener cost about 31 euros. That is equivalent to a kilo price of about 6 euros

- Fifty kilograms of polyester resin Resinpal 1719 including hardener cost about 267 euros. This corresponds to a price per kilo of 5.30 euros

Epoxy resin Resinpal 2301 including hardener

This synthetic resin is a universal material that can be used for almost any application. In addition to the coating and repair tasks, Respinal 2301 is also well suited as a filling compound, repair adhesive or for laminating.

- One kilogram of epoxy resin Resinpal 2301 cost about 18 euros

- Five kilograms of Resinpal 2301 epoxy resin cost about 60 euros. That corresponds to a kilo price of about 12 euros

- Fifty kilograms of resin Resinpal 2301 cost about 585 euros. That corresponds to a kilo price of 11.70 euros

Epoxy resin Resinpal 2401 including hardener

With this resin you can produce high-end products. However, its processing is very demanding because it is mixed with different hardeners. This makes it easy to set in its properties, but it is only recommended for advanced users. The available hardeners allow a processing time of 15 minutes to one and a half hours.

- One kilogram of Resinpal 2401 epoxy resin costs about 26 euros

- Five kilograms of Resinpal 2401 epoxy resin cost about 100 euros. That corresponds to a kilo price of about 20 euros

- Fifty kilograms of Resinpal 2401 epoxy resin cost about 840 euros. That corresponds to a kilo price of 17 euros

Epoxy resin Resinpal 2304 including hardener

The Resinpal 2304 epoxy is a highly specific material developed exclusively for mold making. It is characterized by a good formability and precise sandability. This negative molds can be produced, which are suitable for mass production of other GRP parts. This material is very popular in industry and private use.

- One kilogram of Resinpal 2304 epoxy resin costs about 26 euros

- Five kilograms of Resinpal 2304 epoxy resin cost about 120 euros. That corresponds to a kilo price of about 24 euros

- Twenty kilograms of Resinpal 2304 epoxy resin cost around 450 euros. That corresponds to a price per kilogram of 22.50 euros

As you can see, accurate processing and costing are very helpful in processing epoxy.

More than just clearcoats

The industry today offers epoxy-based solutions for floor coatings, which promise fascinating results. We are talking about dyed or flocced floors and stone carpets. This solution is useful if a used tile, concrete or wooden floor is to be refreshed before a total renovation. The workmanship is pretty quick and easy. However, it is not cheap. For a stone carpet you have to expect 35-70 euros per square meter. Meanwhile, many homeowners have recognized the qualities of stone carpets and choose this solution already in the new building. Another advantage is their easy repairability.

These resin solutions for floor coating consist of a normal 2K resin, which is mixed with fillers and dyes. In pure color coatings, the color comes already mixed in the resin and in the container. Flocking or suitable stones are added by the user himself.

The manufacturers offer a huge selection of different designs and materials. For stone carpets, the usual range is marble, glass and quartz. These three basic materials are available in a huge range of colors, which can also be customized by a clever mix.

Processing of epoxy resin

There are several applications where an epoxy resin floor coating is used. Conventional are concrete sealants, leveling compounds, clear seal or design coatings. Using the example of a concrete seal, we would like to explain the handling of epoxy resin. This base seal is also well suited as a structure for a further coating of epoxy resin.

To make a floor coating from epoxy you need:

- Protective clothing for complete skin protection

- face protection

- powerful cordless screwdriver or with precisely metered rotation speed

- mixing paddle

- possibly flat spade

- vacuum cleaner

- Masking tape for masking

- brush

- small and large paint roller with low pile (max 4 mm)

- thinner

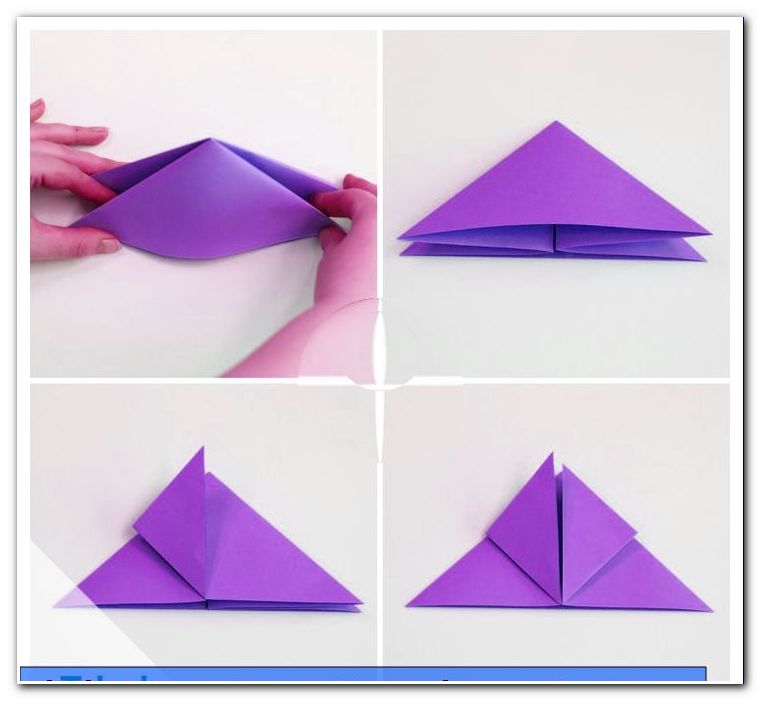

First, the floor is thoroughly cleaned. If the unfinished floor still has cement noses, you can cut them off with the flat spade. Then the room is thoroughly sucked and wiped out. If necessary, then glue the walls and fixtures in the room (eg door frame) with painter's crepe. Now stir the mixture in a clean, ideally new bucket. After mixing add 1/3 thinner. Then let the mixture ripen for about 15 minutes. The very liquid mass you can now easily distribute with brush and roller. Work already opaque, that means crosswise. Allow the base coat to set overnight. Now stir a second mixture. This time she remains undiluted. Apply the coating again with the roller. Work crosswise again and make sure that all pores are closed.

Clear coating is not painted on, but spilled directly from the mixing bucket over the ground. If you are doing S-shaped, you achieve a uniform discharge. Support the spread with a puller. The fluid mass largely self-equilibrates once the soil is completely covered. Go backwards to door and smooth all footprints with the puller. Allow the mixture to harden completely, making sure no one enters the room. This will give you a good result.

Tips for quick readers

- Find out exactly which epoxy resin you need

- Work clean and tidy. Epoxy resin forgives nothing.

- Pay attention to safety at work, especially in the face and eyes

- Always mix exactly according to the mixing ratio. Epoxy resin is a sophisticated material.