Fire Classes / Fire Resistance Classes - Wiki

- To take precautions

- Prevent spread

- What can burn "> Fire resistance - German standard

- Fire resistance classes

- Further markings

- Fire protection classes according to European standard

- Fire protection classes of building parts

- fire walls

- Fire prevention materials

Fire resistance of buildings - a building should provide protection. Normally this affects wind and precipitation. However, fires can easily occur in and around a house. So that a house does not immediately become a fire trap even in a fire, the building materials must be designed accordingly. For this purpose, the fire protection classes were launched. Find out in this text everything that the fire protection classes say.

To take precautions

Prevent spread

The most important thing in an incipient fire is that its spread is delayed as long as possible. For this purpose, the use of heat-resistant materials is necessary. However, the flammability of a building material is only one of the three components contributing to its fire resistance. Fire and fire resistance means in a technical sense:

- Heavy flammability / incombustibility, incl. Smoke development

- Static load capacity at high temperatures

- smoke tightness

- wear limits

Primarily, the material properties of a building material are decisive. Here it is mainly materials with a high thermal resistance, which may even include partially impregnated wood. It is of little use to fire protection if a building does not let any flames through, but allows the heat to pass through virtually unfiltered. Therefore, for example, metals, such as those used in steel beams, untreated no materials with particularly good fire protection properties.

However, for example, the issue of smoke tightness or smoke resistance also the shape of the component comes into play.

What can burn?

In contrast to US-American houses, which are mostly made of wood, in Germany one builds mainly of stone, mortar and concrete. Nevertheless, there can be a lot of fire-promoting materials in and around a house. Until a few years ago this was mainly the wood from the roof truss. Meanwhile, with the insulation materials, another, potential source of fire has come to it. The energy transition has significantly subsidized the insulation of houses. For this purpose, mainly facades were covered with highly effective insulating materials. Mineral-based insulating materials such as glass wool, rock wool or calcium silicate are hardly relevant here in terms of fire technology.

However, the very common polystyrene is currently becoming a huge problem. The reason is that even impregnated styrofoam insulation boards do not offer lasting protection. In addition, the fire retardant, which was used until a few years ago in rigid foam boards, wash out over the years. However, it has proven to be so damaging to the groundwater that it is no longer permitted today as a fire retardant for polystyrene boards. For this reason, the insulation of facades is recommended only with mineral materials.

Of course, what the contractors have no control over is the interior design of a house. Furnishings and curtains still provide the No. 1 fire accelerator in a home fire. However, what can be structurally implemented is the installation of walls and doors that can stop the spread of smoke, flames and heat.

Fire resistance - German standard

The fire resistance in Germany is based on certain standards. They provide an orientation aid, according to which you can design a building optimally fireproof. These standards are:

- DIN 4102-2 "Fire behavior of building materials and components: components, terms, requirements and tests"

- EN 13501 Part 2 "Classification of construction products and types of fire behavior. Part 2: Classification with results from fire resistance tests, with the exception of ventilation systems "

It is quite astonishing that internationally, however, there are a large number of very different standards, which are by no means always congruent.

The fire resistance classes also apply only to pure structures within these standards. Stricter regulations apply to vehicle construction, aircraft construction or shipbuilding. Often, insurers here wrote down very carefully how a material must be approved in order to be used in these applications. In shipbuilding, the fire protection properties of materials are particularly keen.

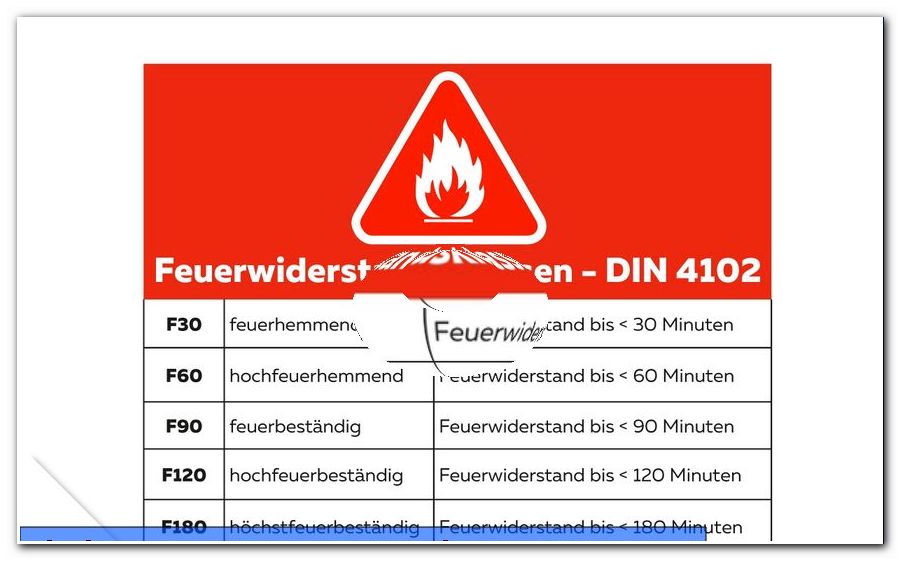

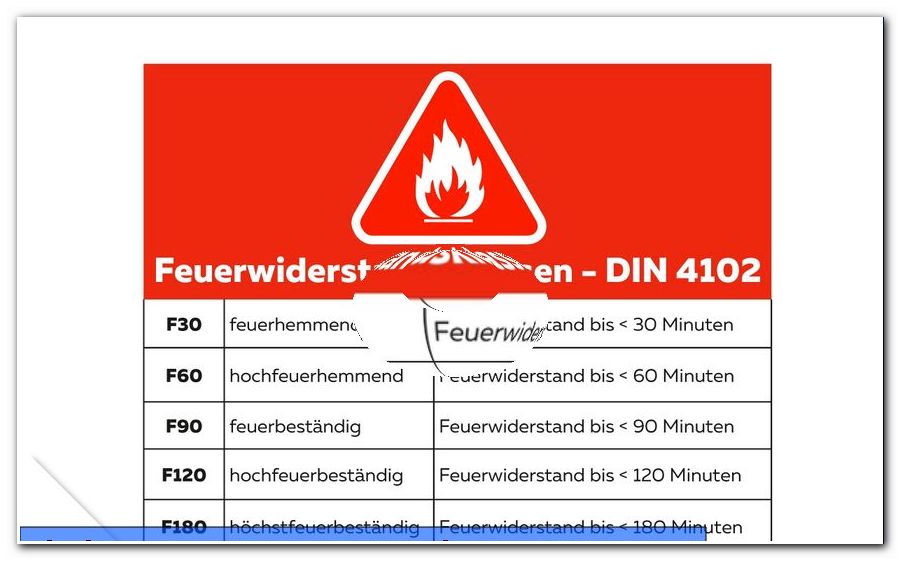

Fire resistance classes

Generally speaking, the fire resistance or fire resistance indicates a period of time. Therefore, the classes in DIN 4102 always have a two- or three-digit number. This number indicates the time in minutes in which a component under a direct flame action:

- does not collapse

- no heat passes

- Smokeproof closes

Which of these properties applies to the respective component depends on the individual case. The reading is therefore in the DIN 4102:

F30: The building material is considered to be "fire retardant" and can withstand direct flame exposure for 30 minutes.

F60: The building material is considered to be "high fire retardant and can withstand 60 minutes of direct flame exposure

F90: The building material is considered "Fire Resistant" and can withstand 90 minutes of direct flame exposure

F120: The building material is considered "High Fire Resistant" and can withstand 120 minutes of direct flame exposure

F180: The building material is considered to be "High Fire Resistant" and can withstand a full flame exposure for a full three hours.

However, these data were always found under laboratory conditions. Especially with plastic building materials such as concrete, plaster or mortar, the flame retardant effect depends significantly on the layer thickness. If a plaster is touted as "fire-resistant", then the promised 90 minutes can only withstand, if it is applied in the prescribed layer thickness. This is very important, for example, in composite thermal insulation systems.

Decisive for the designation of fire protection classes is the number. The prefixed letter may vary, depending on which component it is.

The F is generally used for stairs, walls, false ceilings, supports, fire-resistant glazing and heat shields on the side away from the fire.

For fire doors, such as doors, flaps or gates, the letter T is used.

Sight glazings with only one-sided fire protection without protection against heat radiation are marked with a G. This is used for example in single-layer glass. Although it brakes the flames, but allows the heat through virtually unhindered. Objects located too close to the glass may ignite in spite of the mechanical separation from the source of the fire. It does not matter how thick the glass is. Even bulletproof glass conducts heat so well that it can provide almost no protection against heat breakdown.

Ventilation ducts and ventilation ducts are very important, especially in terms of smoke-tightness. They are marked with the letter L. If shut-off devices are installed in the ventilation ducts, they are classified with the letter K.

E marks the fire protection classes of electrical installation aids. These include cable trays with the associated studs, conduits or cable ducts. The fire protection is demanded on both sides of these components: Neither flames from the outside must access the wiring, nor may a cable fire within a pipe lead to a propagation of the flames within the given fire protection class.

Pipe seals and pipe ducts are given an R to identify the fire protection class.

Non-supporting exterior walls are marked with a W. These include the famous "fire walls".

Further markings

In many building materials, an originally combustible material is improved by the addition of impregnating agents in its fire retardancy. Nevertheless, the classification must point to the flammability of the original material. Therefore, these building materials receive a hanging B. Impregnated wood, for example, is usually labeled "F30-B"

Conversely, combustible building materials are classified according to their flammability.

This classification is according to DIN 4102

A: Non-combustible materials (concrete, stone, mineral wool ...)

A1: Non-flammable substances with small amounts of organic material

A2: Non-combustible substances with addition of combustible substances (laminated mineral wool)

B: combustible materials (wood, polystyrene, plastics)

B1: Flame retardant materials (impregnated wood)

B2: Normally flammable materials (non-impregnated wood)

B3: highly flammable substances (prohibited as building material, eg paper)Fire protection classes according to European standard

It is now somewhat confusing that the fire protection classes according to the European standard EN 13501 Part 2 are similar to identical awarded. However, they differ somewhat in meaning. Basically, the European standards also consist of a letter and number combination. Also, the meaning of the attached number is identical to the DIN standard, namely the duration of stability in minutes. However, the preceding letter indicates the type of resistance. These are.

C: "Closing" Self- closing mechanism of a smoke door or smoke damper

E: "Etanchéité" This means "room closure" and refers to the prevention of a passage of fire to the other side of a wall.

G: Resistance to spontaneous combustion on contact with red-hot or hot soot

I: "insulation" Thermal insulation or heat loss when transferred through a wall.

K: General fire protection effect

M: "Mechanical" resistance to mechanical effects such as impacts or impacts against a wall or a supporting pillar.

P: "Power" Maintaining a supply of electricity, especially for cabling.

R: "Resistance" General maintenance of the carrying capacity of a wall or a buttress.

S: "Smoke" smoke tightness, reliability of smoke removal, shielding from penetrating smoke

W "Radiation" Radiant heat, heat radiation. Originally "Watt" was used, where the "W" comes from.

However, most of the information is well transferable between standards. What is called "F90" according to the DIN standard can be found in the Euronorm under "REI 90". The Euronorm is a bit more precise here, as it demands the carrying capacity as well as the insulation and the inhibition of the fire transfer with the combination of letters REI. These include, for example, partition walls in buildings.

Fire protection classes of building parts

The most important parts of the building are divided into dedicated fire protection classes according to German and European standards. A building that does not meet these classes is considered not eligible. It is the responsibility of the architect or civil engineer to plan the building accordingly and to supervise the appropriate execution. The specifications are in accordance with EU standard and DIN standard:

Fire retardant version

- Load-bearing components without room closure: R 30-60 / F 30-60

- Structural elements with room finishes: REI 30 / F 30-60

- Non-load-bearing interior walls: EI 30-60 / F 30-60

- Non-supporting exterior walls: E 30-60, EI 30-60 / W 30-60

- Raised floors: REI 30-60 / F 30-60

Fireproof execution

- Load-bearing components without room closure: R 90-120 / F 90-120

- Load-bearing components with room closure: REI 90 / F 90-120

- Non-load-bearing interior walls: EI 90-120 / F 90-120

- Non-supporting exterior walls: E 90-120, EI 90-120 / W 90-120

- Raised floors: REI 90-120 / F 90-120

As a "fire wall" in a building today only "load-bearing parts with room closure" and "non-load-bearing interior walls" with a fire resistance class of at least F 90. Although there are also external fire walls, but these are decoupled from the actual building. In addition, they have additional requirements.

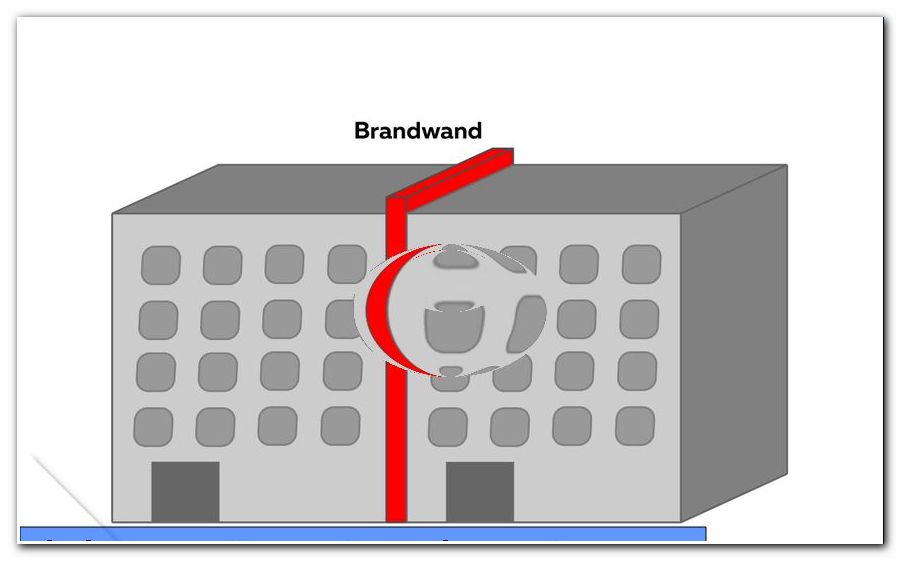

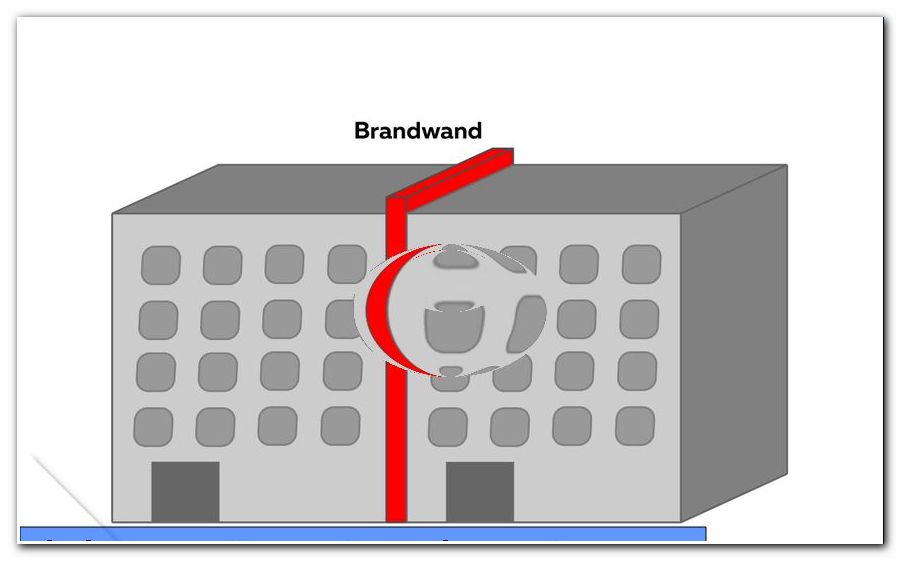

fire walls

Fire walls are used to prevent a fire inside a building or skipping a fire from one building to the next. For this they must:

- Made of fire-resistant material, so at least reach the class F90

- be mechanically strong, even with side impacts according to Euronorm class R

- Have sufficient thickness to prevent heat transfer

- Protruding beyond the roof area (for external fire walls between two buildings)

- Within the building to the roof area protrude

- Do not allow openings such as openings, windows or doors. Ventilation slots or boreholes for water pipes are also inadmissible in the case of external fire walls

- be provided with suitable flaps and doors, which in turn have appropriate fire protection properties including self-contained closure, if it is internal fire walls.

- may have to meet the requirements of the insurance.

Fire walls will be required if the outside wall of a building is too close to the outside wall of the neighboring property. A fire flashover should be prevented. With the choice of building material, which also has a sufficient insulating effect, a heat breakdown is prevented.

Internal fire walls become necessary when a building has to be divided into individual fire compartments because of its size. This allows for accurate evacuation plans and more accurate rescue operations.

Fire prevention materials

Burnt bricks One of the oldest and most proven building materials for the construction of fire-resistant building elements is the fired brick. However, he is not very isolated because of his massiveness. Flames are reliably prevented. Also, a sufficiently thick wall can very reliably intercept mechanical effects. However, a brick wall heats up quite quickly to the point that on the side facing away from the fire, there may well be a follow-up edge. Therefore, multi-layered fire-barrier elements are ideal. If the brick wall is supplemented, for example, with a lining made of aerated concrete blocks or at least mineral insulating wool, heat transfer is also reliably prevented.