Lay sewage pipes (KG and HT pipes) - instructions

- Division of sewers

- Pipe dimensions and their use

- Fittings of the drainage pipe

- Sheets

- siphon

- feeders

- reducer

- Clutches

- cleaning openings

- backflow

- roof ventilation

- clamps

- Lay sewage pipes

- Determine material requirements

- The tool requirement

- Preliminary information on HT pipe laying

- Drain Pipe Installation

- Measuring

- The cutting to length

- Deburring

- Chamfering

- Apply the lubricant

- The joining together

- Tips for quick readers

Today's modern sanitation standards allow us to decontaminate and dispose of all waste products of the house. These include sewage pipes. A few years ago, made of sheet steel, stoneware, lead and cast iron, today plastic pipes are used in the house installation, which are not only quick and easy to assemble, but also inexpensive and rot proof. But with a simple plugging together, it is not done, much has to be considered in the correct drain installation.

Drainpipes are easy to get and put together quickly. The plastic pipes made of PVC (polyvinyl chloride) or PP (polypropylene) are almost unbreakable, acid-resistant and easy to install.

The range of fittings is plentiful and offers a solution for every application and every problem. In addition to standard tubes, elbows, reducers and various branches, there is a whole range of different fittings. Quick you are overwhelmed by the sheer abundance of possibilities to build a drain line. Already at the beginning there is a question: HT pipe or rather KG pipe ">

Division of sewers

Sewer pipes are divided into different areas and have different requirements and functions. Waste water pipes are divided into two gradients: horizontal pipes and downpipes.

One differentiates against the flow direction following line sections:

- connecting channel

- The connecting channel leads from the street channel to the property boundary, alternatively to the first cleaning opening on the property.

- underground pipe

- The ground line is laid on the property in the ground and leads from the house in the connection channel.

- manifold

- The manifold is an exposed conduit for receiving the drop and connection cables.

- penstock

- Is a drain pipe that leads vertically through the house. This means that it passes through several storeys, is ventilated via the roof and leads dirty water to a collecting line or a ground line.

- connecting cable

- Single connection lines lead from the odor trap of a drainage object to the junction with a secondary line.

- Collective connection lines combine several individual connection lines up to the case, collective or basic line.

- connecting line

- A connection line is a line between the drainage point and the odor trap.

- vent line

- This line does not absorb wastewater. It aerates and deaerates the drainage system.

Pipe dimensions and their use

HT pipes are available in the sizes DN 32 to DN 160. By default, however, only four sizes are used indoors in the family house, namely DN 40 to DN 110, rarely even DN 32. The use and the size of the pipe diameter are aimed after use and the drainage object to be connected in the house.

DN 40

DN 40 pipes and fittings are the smallest size in the HT drainage system. With this size, only hand basins and washbasins are connected.

DN 50

DN 50 pipes and fittings are the most commonly used size for drainage systems. With this size shower and bathtubs, washing machines, sinks, dishwashers and washing machines up to 6 kg dry laundry are connected.

DN 75

DN 75 pipes and fittings are used for manifolds and washing machines whose dry laundry contains 6 to 12 kg.

DN 110

DN 110 pipes and fittings are used for WC drain pipes and risers.

Fittings of the drainage pipe

Sheets

Bows are used to give lines a new direction. However, it is not irrelevant which bow is used. 87 ° bends are never installed in corners or other directional changes. They serve purely for connection to drainage points, for example, after sinks, showers, bathtubs, etc.

In order to prevent congestion and deposits in the pipe, changes of direction greater than 45 ° are made with two bends. Between both bows a so-called intermediate piece is inserted, which is 25 cm long.

siphon

A special type of bows is the siphon arch, which serves as a connection to the sewer pipe for sinks, washing machines, toilets, etc.

For example, the odor trap of the washbasin is connected to it. The difference to a normal bow is the larger sleeve and a larger and differently shaped seal.

feeders

Branches are used to merge pipes. As with bows, there are rules that must be adhered to, so that an optimal air flow in the pipe is maintained and there are no backwashes in the pipe. For example, double branches and branches on horizontal pipes may only be designed with 45 ° branches to restrict backwashes in the pipe.

reducer

Reducers are used to pass a smaller diameter tube into a larger diameter tube. In order to ensure the air movement in the pipes, the correct installation of a reducer is important. The smaller pipe connection, which merges into the larger pipe, is always up.

Clutches

Muff is not only called the end of the tube where the seal is located, but it is in the artisan Slang also a fitting in itself so called, this is called double socket or sliding sleeve. Double sleeves are used to connect fittings or pipes. Sliding sleeves are a special type of double sleeve. With this sleeve, it is possible to push it back and forth on a pipe. It is used in repairs to replace only parts of defective pipes.

cleaning openings

With the help of cleaning openings, pipes can be opened to eliminate blockages in pipes with a water jet, a cleaning spiral or similar devices. It is important that cleaning openings must be closed gas-tight. Also, cleaning ports serve as access to the pipe to inspect lines with special cameras and locate problems or leaks. To install are cleaning openings inside the house before connecting a downpipe to a base or manifold.

backflow

Backflow stops are used to prevent a so-called backwater. This happens, for example, in heavy rainfall. The sewer system is overloaded and the rainwater pushes through the underground line back into the house. The result is that wastewater enters the apartment from all drainage outlets. For this reason, backflow closures are installed at the last point of the house, where the manifold goes into the baseline. This ensures that wastewater can only flow in one direction, outside. However, it is important to ensure that every year a maintenance of the backwater stopper is carried out, possibly even months ago, in which to be expected with plenty of rain.

roof ventilation

The drainpipe must be vented to prevent negative pressure in the system, which can suck the water out of the trap and thus open the odor barrier. The result would be sewage odors in the apartment. For this purpose, the downpipe is led through the roof and mounted a so-called roof vent.

clamps

Clamps are the attachment of the HT pipe to the house. Preferably steel clamps are used with rubber insert. In this case, there is a clamp distance in lying lines of a maximum of ten times the nominal diameter of the pipe. In the case of downpipes, clamps are set after two meters at the latest. As an example, consider a DN 50 pipe. The nominal width is 50 mm multiplied by 10 this gives 500 mm. So it must be set after 50 cm at the latest a clamp. The clamps are usually attached shortly after the sleeve of the pipe. When changing direction, clamps are set shortly after the arc.

Lay sewage pipes

Determine material requirements

Before starting with the own work of laying the pipes and setting up the drainage objects, the material needs to be determined. For this, the rooms are set up in the drainage objects are measured. These include the kitchen, toilet, bathroom, the connecting room in the basement and all the rooms through which the sewage pipe is led. Also needed is a cross section of the house.

The easiest way to do this is checkered paper (even more accurate is graph paper). On a scale that is determined by itself, the rooms are traced. It is recommended here for easy calculation a useful scale. A common value here is a box on the paper equal to 10 cm in space. For larger rooms, sheets may have to be glued together with adhesive tape.

Although this preparation costs some time, it saves a lot of trouble and trouble during the actual construction.

If the drainage objects in the room are drawn in the correct dimensions, the points of the downpipes are drawn. Afterwards the manifolds and connecting cables will be shown on the sheet.

Once this step has been completed, the nominal diameter of the pipes can now be noted on the lines drawn, it is also advisable to draw in the clamps. Once this step has been completed, the clamps can now be counted and the pipe length determined. Incidentally, which dewatering article is connected with which nominal diameter has been noted above. If this step has been edited, it will go to the last step. At this point, a bit of hard work is needed. Step by step, it is now written down from the last drainage object to the connection of the basic line, which fittings are needed. Starting with the siphon angle, over bends, branches, reducers, cleaning openings etc.

Finally, you should think about a sound insulation, so that flow noise of the sewage in the house can not be heard.

Thus, it is quite easy to determine the material requirements. Furthermore, you should buy the right mounting material for the pipe clamps.

The tool requirement

The tool requirements for the installation of HT pipe are limited. The following things should be considered:

- Zollstock (colloquially also Schmiege)

- Carpenter's pencil

- carpet cutter

- hacksaw

- cutting charge

- gloves

- Drill, cordless screwdriver

- screwdriver

- fine file

- Lubricant, alternatively commercially available Fit

Preliminary information on HT pipe laying

Drain pipes are usually laid in inhabited floors in a cavity or behind a plasterboard wall. Here the pipes are attached to the wall. In the basement you fix the pipes under the ceiling, the attachment takes place either on the wall or on the basement ceiling.

HT pipes are not embedded in concrete. Like all materials, the HT pipe works. Heat is involved, in cold weather it contracts. A fixation in masonry is therefore not possible, since a fixation can cause the bursting of the tube.

Sewer pipes are self-cleaning pipes, meaning the water flushes all the products that come into the sewer pipe from it. For this purpose, it is necessary that the pipe is either laid vertically or has a slope, which leads away from the dewatering object. A toilet would therefore be built with a slope to the down pipe and a manifold would be built with a slope to the baseline. The gradient is between 1.0 and 1.5%. As a rule of thumb, there is 1 cm of slope per 1 m of pipeline.

Furthermore, it is important to pay attention to how the HT pipe is laid. The sleeve end of the pipe always points always in the direction from which the water or sewage comes.

Drain Pipe Installation

Measuring

Before a pipe can be cut, the length of the pipe must first be determined. This is done simply with a yardstick, colloquially called also Schmiege. Make sure that you also measure the piece of pipe that is later in the sleeve of the next pipe or fitting stuck. The point of cutting to length, as the shortening of the pipe is also called, is marked with a carpenter pencil.

At this point, a special feature of laying HT pipe is used. HT pipe rules on heat and cold. When heated, the tube expands, in the cold it contracts. This expansion of the material must be taken into account. For this reason, 1 cm of the pipe is cut to length.

The cutting to length

To cut the pipe to use a fine or iron saw. To ensure a right-angled cut, the tube is placed in a cutting drawer. These are available to buy, but are also quite easy to make yourself. If the pipe is firmly in the cutting drawer, it is now cut to length using the fine or iron saw.

Deburring

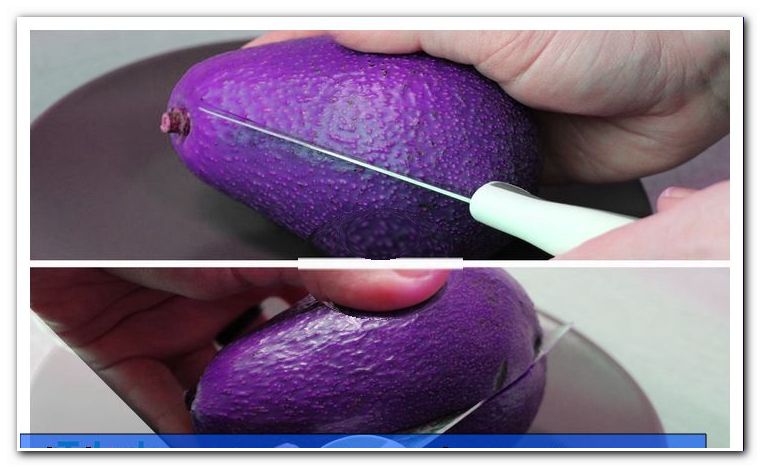

After cutting the burr is removed both inside and outside on the pipe with a standard utility knife. This is important in order to ensure a proper seal and to prevent any dirt particles from accumulating on the ridge inside the pipe, which can lead to clogging of the pipe.

Chamfering

The pipe ends as well as the fittings are chamfered at the end to achieve good insertion into the sleeve. With a fine file, the pipe is now chamfered to a width of about 1 cm with a file.

Apply the lubricant

Lubricant is used to get the tube into the next sleeve. Can be used for this also commercially available Fit. Both the sealing ring and the pipe end are evenly coated.

The joining together

Before both pipe parts or molded parts are brought together, once again the correct seat of the seal is checked. The lubricant should thus be distributed evenly and there is no dirt on the seal. Now the pipes can be pushed together completely. After a few centimeters you notice the stop, the tube is in the sleeve. As a final step, the insertion depth of the pipe is then marked and the pipe is retracted again to the previously mentioned centimeter.

Tips for quick readers

- Gradient is between 1.0 and 1.5%

- Observe the expansion compensation of 1 cm

- Nominal diameter of the HT pipe is based on the drainage object

- Downpipes are laid in DN 110

- Manifolds will be moved to DN 75

- Manifolds for toilets will be laid in DN 110

- Distance of the clamps with lying lines maximally ten times the nominal width of the pipe

- Distance of the clamps for downpipes maximum two meters

- Attach clamps to the downpipe behind the sleeve.

- Deburr cut pipes or fittings and chamfer them again

- Check the seal for damage and good fit

- Never use force to connect pipes and fittings, use lubricant